In metalworking, the machine used to press, shape, or cut metal is broadly known as a press. However, this single term covers a wide range of machines, most notably the mechanical press, hydraulic press, and pneumatic press. Each operates on a different principle and is chosen based on the specific requirements of the job, such as the force, speed, and control needed.

The critical takeaway is not to find a single "metal press," but to understand how the three main types—hydraulic, mechanical, and pneumatic—offer distinct advantages in force, speed, and control. The right choice depends entirely on the manufacturing goal, from high-speed stamping to heavy-duty forging.

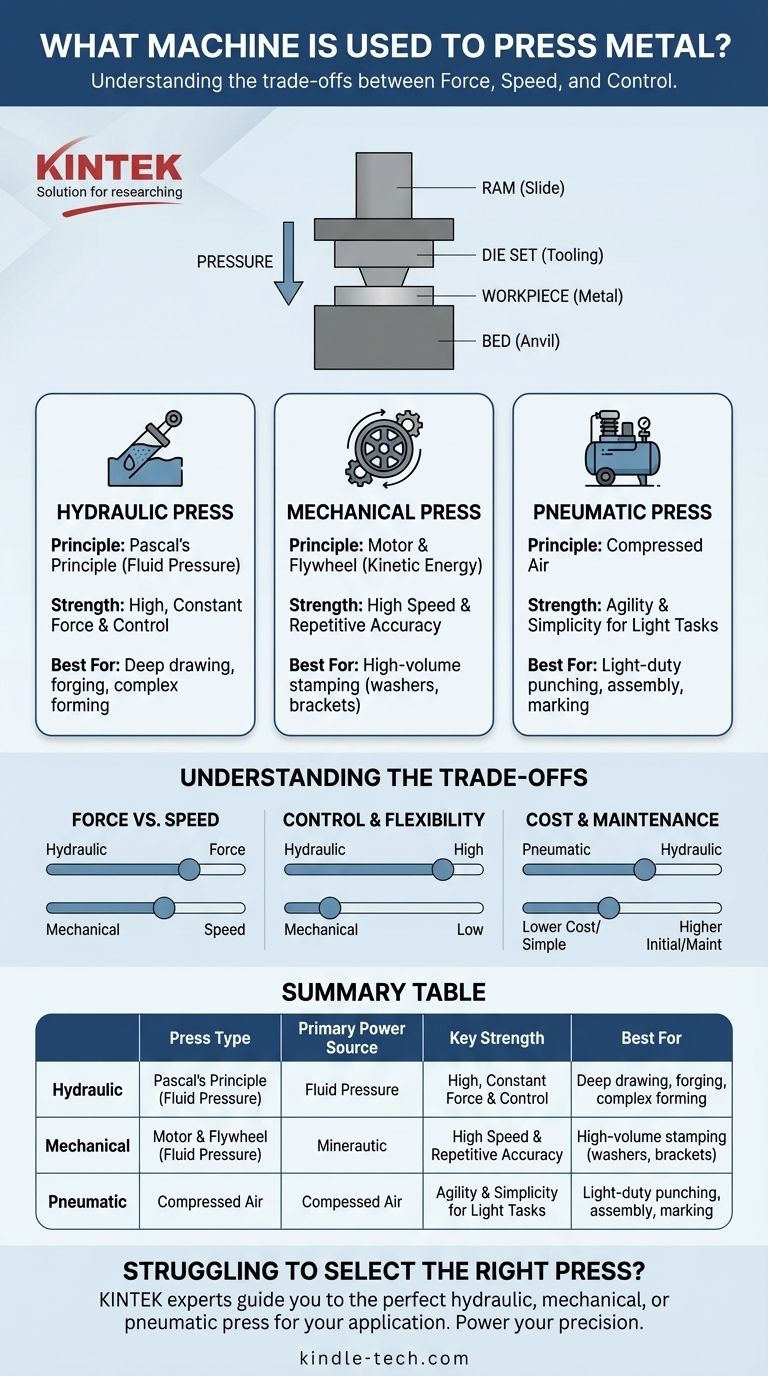

The Core Function: How a Metal Press Works

At its most fundamental level, a metal press is a machine tool that changes the shape of a workpiece by applying pressure. This process is used for a vast array of applications, including stamping, punching, forging, and forming.

The Basic Principle: Force and Dies

All presses operate on a simple concept. A ram (or slide) moves towards a stationary bed (or anvil).

Tooling, known as a die set, is attached to both the ram and the bed. A metal workpiece is placed between the upper and lower dies, and the press applies force, causing the metal to be cut, bent, or formed into the desired shape.

Key Processes: Stamping, Forming, and Forging

The term "pressing metal" can refer to several distinct processes.

Stamping generally involves using a die to cut a shape from a metal sheet (blanking) or create a shallow impression (coining). Forming and bending create shapes like angles and channels, often using a machine called a press brake. Forging involves shaping a solid block of hot or cold metal with immense compressive force.

The Three Main Types of Presses

The "engine" that drives the ram is what truly defines the press and its capabilities. The choice between them is a foundational decision in manufacturing process design.

The Hydraulic Press: Unyielding Force and Control

A hydraulic press is powered by one or more hydraulic cylinders. It operates on Pascal's principle, where a fluid under pressure is used to generate immense, controllable force.

This design gives the hydraulic press its signature characteristic: the ability to deliver its full rated force (tonnage) at any point in the ram's stroke. This makes it exceptionally well-suited for tasks that require sustained pressure, such as deep drawing car body panels or forging thick billets of steel.

The Mechanical Press: Speed and Repetitive Accuracy

A mechanical press uses a motor to spin a large, heavy flywheel, which stores kinetic energy. When the operator engages the press, a clutch connects the flywheel to a crankshaft that drives the ram up and down in a continuous motion.

Its force is not constant; it is highest at the very bottom of the stroke. The primary advantage of a mechanical press is speed and repeatability, making it the workhorse for high-volume production of stamped parts like washers, brackets, and electronic components.

The Pneumatic Press: Agility and Simplicity

Also known as an air press, a pneumatic press uses compressed air to drive a piston and actuate the ram. It delivers quick, repetitive strokes but generates significantly less force than hydraulic or mechanical systems.

These presses excel at light-duty, high-speed applications. They are often used for piercing thin materials, light assembly work, marking parts, and other tasks where speed is more critical than raw power.

Understanding the Trade-offs

Choosing a press involves balancing competing factors. No single type is universally superior; each represents a different set of compromises.

Force vs. Speed

This is the most fundamental trade-off. Mechanical presses are built for speed, capable of hundreds of strokes per minute, but their force varies throughout the stroke. Hydraulic presses are generally slower but provide constant, massive force that can be held or "dwelled" for extended periods.

Control and Flexibility

Hydraulic presses offer unparalleled control. The operator can precisely adjust the stroke length, speed, and pressure on the fly. This flexibility is crucial for complex forming operations and for working with sensitive materials that might tear under the abrupt impact of a mechanical press.

Cost and Maintenance

For high-volume, standardized jobs, a mechanical press is often more energy-efficient and has a lower cost-per-part. Hydraulic presses can have a higher initial cost and require more maintenance related to seals, pumps, and hydraulic fluid, but their flexibility can be invaluable for custom or low-volume work. Pneumatic presses are the simplest and least expensive for light applications.

Making the Right Choice for Your Application

Selecting the correct press begins with a clear understanding of your primary objective.

- If your primary focus is high-volume production of simple stamped parts: A mechanical press is the most efficient and cost-effective solution due to its high speed.

- If your primary focus is forming complex shapes, deep drawing, or forging: A hydraulic press provides the necessary constant force and precise control to prevent material failure.

- If your primary focus is rapid, light-duty punching, assembly, or marking: A pneumatic press offers a fast, simple, and low-cost tool for the job.

By matching the machine's operating principle to your specific application, you ensure an efficient, reliable, and high-quality manufacturing process.

Summary Table:

| Press Type | Primary Power Source | Key Strength | Best For |

|---|---|---|---|

| Hydraulic Press | Hydraulic Fluid | High, Constant Force & Control | Deep drawing, forging, complex forming |

| Mechanical Press | Motor & Flywheel | High Speed & Repetitive Accuracy | High-volume stamping (washers, brackets) |

| Pneumatic Press | Compressed Air | Agility & Simplicity for Light Tasks | Light-duty punching, assembly, marking |

Struggling to select the right press for your metalworking project? The wrong choice can lead to inefficiency, poor quality, or damaged materials. KINTEK specializes in lab and industrial equipment, helping you navigate the critical trade-offs between force, speed, and control. Our experts can guide you to the perfect hydraulic, mechanical, or pneumatic press for your specific application—ensuring a reliable and high-quality manufacturing process. Contact our team today for a personalized consultation and let KINTEK power your precision.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What role does a laboratory hydraulic pellet press play in fly ash utilization? Enhancing Adsorption and Flow Control

- How does high-precision pressure control in hydraulic presses affect the quality of solid-state battery electrodes?

- Why is a precision laboratory hydraulic press required for manufacturing molybdenum target green bodies?

- What is the primary function of a laboratory hydraulic press in the preparation of graphite electrodes?

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What role does a laboratory hydraulic press play in all-solid-state battery electrode evaluation? Key Roles Explained

- What are the different types of sample preparation? Achieve Accurate & Reliable Analytical Results

- Do hydraulic presses need electricity? Discover the Power Source for Your Workshop