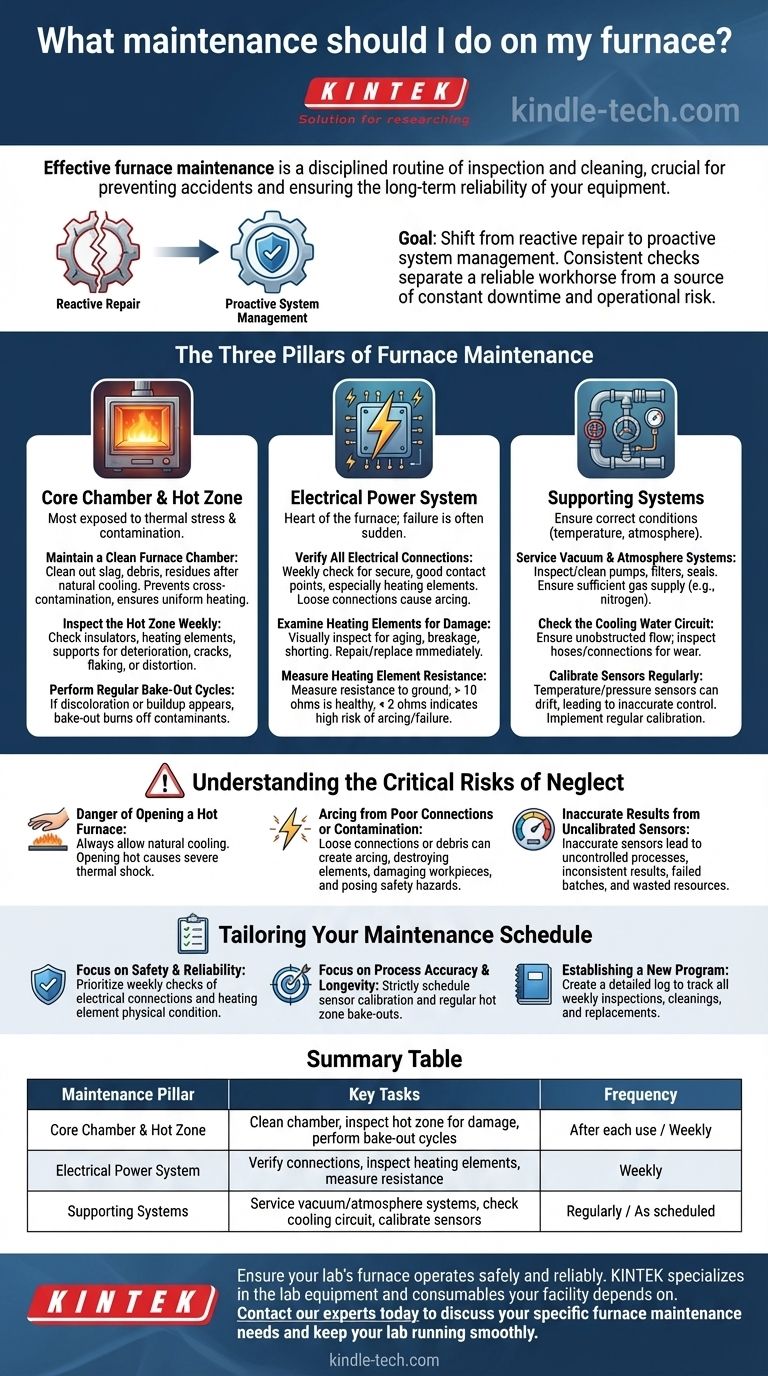

Effective furnace maintenance is a disciplined routine of inspection and cleaning, crucial for preventing accidents and ensuring the long-term reliability of your equipment. At its core, this involves regularly cleaning the furnace chamber, meticulously inspecting all electrical connections and heating elements, and verifying the integrity of auxiliary systems like cooling circuits and vacuum pumps.

The goal of furnace maintenance is to shift from reactive repair to proactive system management. Consistent checks on electrical integrity, contamination levels, and system performance are what separate a reliable workhorse from a source of constant downtime and operational risk.

The Three Pillars of Furnace Maintenance

Proper maintenance can be organized into three key areas: the core heating chamber, the electrical power system, and the essential supporting systems. Neglecting any one of these can compromise the entire operation.

Pillar 1: The Core Chamber and Hot Zone

This is where the work happens, and it's the area most exposed to thermal stress and contamination.

Maintain a Clean Furnace Chamber

After the furnace has cooled naturally, always clean out any slag, debris, or process residues. A clean chamber prevents cross-contamination and ensures more uniform heating.

Inspect the Hot Zone Weekly

The hot zone—including insulators, heating elements, and work supports—should be examined weekly. Look for signs of deterioration like cracks, flaking insulation, or physical distortion.

Perform Regular Bake-Out Cycles

If you notice discoloration on insulators or buildup in gas nozzles, a bake-out cycle can help clean the hot zone. This process burns off contaminants that accumulate over time.

Pillar 2: The Electrical Power System

The electrical system is the furnace's heart. Its failure is often sudden and can be catastrophic, making regular inspection a non-negotiable task.

Verify All Electrical Connections

At least once a week, check that all electrical connections are secure and in good contact. Pay special attention to the connection points for the heating elements, as loose connections here can cause arcing and failure.

Examine Heating Elements for Damage

Visually inspect the heating elements for signs of aging, breakage, or short-circuiting. Any compromised element should be repaired or replaced immediately to prevent uneven heating or complete failure.

Measure Heating Element Resistance

For a more technical check, measure the heating element's resistance to ground. A healthy reading should be greater than 10 ohms; a reading below 2 ohms indicates a high risk of arcing and imminent failure.

Pillar 3: Supporting Systems

These systems ensure the furnace can operate under the correct conditions, from temperature to atmosphere.

Service Vacuum and Atmosphere Systems

If you use a vacuum furnace, this includes inspecting and cleaning the vacuum pump and replacing filters and seals. For atmosphere furnaces, ensure your supply of process gas, such as high-purity nitrogen, is sufficient.

Check the Cooling Water Circuit

Ensure the cooling water circuit is unobstructed and flowing smoothly. Inspect hoses and connections for wear or damage and replace them proactively.

Calibrate Sensors Regularly

Temperature and pressure sensors can drift over time, leading to inaccurate process control. Implement a regular calibration schedule to ensure your furnace is operating at the specified parameters.

Understanding the Critical Risks of Neglect

Skipping maintenance isn't a trade-off; it's an acceptance of risk. Understanding these risks reinforces the importance of a consistent maintenance routine.

The Danger of Opening a Hot Furnace

After a cycle, always cut the power and allow the furnace to cool down naturally. Opening the furnace door while it is still hot can cause severe thermal shock to the chamber and heating elements, drastically reducing their lifespan.

Arcing from Poor Connections or Contamination

A loose electrical connection or conductive debris in the chamber can create an electrical arc. This can destroy a heating element, damage the workpiece, and pose a significant safety hazard.

Inaccurate Results from Uncalibrated Sensors

If your temperature or pressure sensors are not accurate, your process is not controlled. This leads to inconsistent results, failed batches, and wasted resources, directly impacting quality and efficiency.

Tailoring Your Maintenance Schedule

Use these guidelines to build a routine that matches your operational priorities.

- If your primary focus is safety and reliability: Prioritize weekly checks of all electrical connections and the physical condition of the heating elements.

- If your primary focus is process accuracy and longevity: Implement a strict schedule for sensor calibration and regular hot zone bake-outs to prevent contamination.

- If you are establishing a new maintenance program: Start by creating a detailed log to track all weekly inspections, cleanings, and any component replacements.

A well-maintained furnace is a predictable asset, not an unpredictable liability.

Summary Table:

| Maintenance Pillar | Key Tasks | Frequency |

|---|---|---|

| Core Chamber & Hot Zone | Clean chamber, inspect hot zone for damage, perform bake-out cycles | After each use / Weekly |

| Electrical Power System | Verify connections, inspect heating elements, measure resistance | Weekly |

| Supporting Systems | Service vacuum/atmosphere systems, check cooling circuit, calibrate sensors | Regularly / As scheduled |

Ensure your lab's furnace operates safely and reliably. KINTEK specializes in the lab equipment and consumables your facility depends on. From replacement heating elements and thermocouples to expert advice on maintenance schedules, we provide the support you need to minimize downtime and maximize productivity. Contact our experts today to discuss your specific furnace maintenance needs and keep your lab running smoothly.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the precautions for heat in the laboratory? Essential Safety Rules to Prevent Burns and Fires

- Can calcination be done in a muffle furnace? Yes, for precise air-atmosphere heating.

- What are the results of calcination? A Guide to Purification and Material Transformation

- Can a muffle furnace be used for calcination? Achieve Pure, Controlled Thermal Decomposition

- What is the specific heat capacity for melting? Clarifying Latent Heat vs. Specific Heat