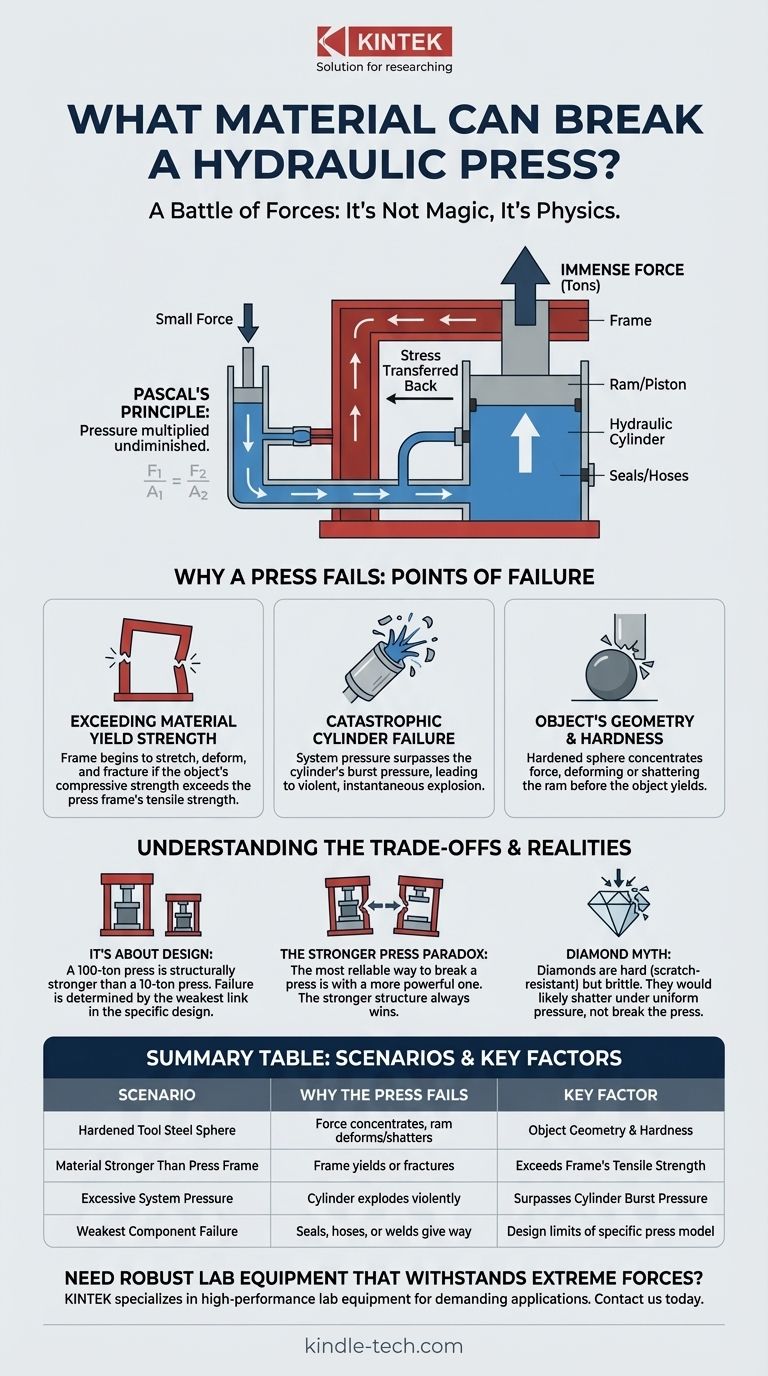

In short, a hydraulic press breaks when it attempts to crush an object that is stronger than the press itself. This isn't about a single "magic" material, but a fundamental battle of forces. If the force required to deform or break an object exceeds the structural integrity of the press's own frame, cylinder, or seals, the press will be the one that fails.

A hydraulic press is not an unstoppable force. It is a machine with engineered limits, defined by the strength of its materials and design. It fails when the object it's compressing effectively "pushes back" with a force that surpasses the press's own yield strength, causing its components to bend, stretch, or shatter.

The Principle of Immense Force: How a Press Works

To understand what can break a press, you must first understand how it generates force. The entire machine is an application of a core physics principle.

Pascal's Principle in Action

A hydraulic press uses Pascal's Principle, which states that pressure applied to a confined fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, a small amount of force applied to a small piston creates immense pressure in the hydraulic fluid. This high-pressure fluid then pushes against a much larger piston, multiplying the initial force into the crushing power measured in tons.

The Components Are the Points of Failure

A press is a system, and it is only as strong as its weakest link. The primary components are:

- The Frame: Usually a heavy steel structure that contains the immense forces.

- The Hydraulic Cylinder: The chamber where fluid pressure builds to push the ram.

- The Ram/Piston: The moving component that makes contact with the object.

- Seals and Hoses: Components that contain the high-pressure fluid.

Failure in any one of these parts means the failure of the entire machine.

Why a Press Fails: A Battle of Strengths

Failure occurs when the object being crushed resists deformation so effectively that the stress is transferred back onto the press's own structure, pushing it beyond its limits.

Exceeding Material Yield Strength

Every structural material has a yield strength—the point at which it begins to permanently deform—and an ultimate tensile strength, the point at which it breaks. The frame of a hydraulic press is typically made from high-strength steel.

If you attempt to crush a block of material with a higher compressive strength than the press frame's tensile strength, something has to give. The C-frame or H-frame of the press will begin to stretch and eventually fracture.

Catastrophic Cylinder Failure

The most dangerous failure is when the hydraulic cylinder itself gives way. To crush a very strong object, the system's pressure must be increased. If this pressure exceeds the burst pressure of the cylinder walls, the cylinder will explode.

This is not a simple leak; it is a violent, instantaneous release of stored energy, launching metal fragments and high-pressure fluid.

The Object's Geometry and Hardness

It's not just the material, but its shape and hardness. A small, solid sphere of hardened tool steel is exceptionally difficult to crush because it concentrates the force onto tiny points and has no easy axis for deformation. The press ram itself might shatter or deform before the sphere does.

Understanding the Trade-offs and Realities

The idea of an "uncrushable" object is more complex than it appears. The outcome is always a matter of engineering design and material science.

It's About Design, Not Just Material

A 100-ton press is not simply a bigger version of a 10-ton press; it is fundamentally more robust. Its frame is thicker, its cylinder walls are stronger, and its welds are designed for higher stress. The failure point is always determined by the weakest part of that specific design.

The "Stronger Press" Paradox

The most reliable way to break a hydraulic press is with another, more powerful hydraulic press. This perfectly illustrates the principle: the stronger structure will always win.

What About a Diamond?

A diamond is the hardest known natural material, but hardness is not the same as strength. Hardness is resistance to scratching. While diamonds have high compressive strength, they are also brittle and full of microscopic flaws. Under the uniform, immense pressure of a press, a diamond would likely shatter into dust rather than break the machine.

Making the Right Choice for Your Goal

Understanding how a press fails is about appreciating the engineering limits and the incredible forces at play.

- If your primary focus is the physics: The key takeaway is that an object will break a press if its compressive strength and geometry require a force that exceeds the yield strength of the press's own structural components.

- If your primary focus is a specific material: The most likely candidate is not a mythical substance, but a precisely engineered object—like a solid sphere of tungsten carbide or a purpose-built block of a hardened superalloy—that is itself stronger than the steel of the press.

- If your primary focus is the engineering: Remember that a press fails due to its own design limitations. The "uncrushable" object is simply one that exposes the weakest link in the system, whether it's the frame, cylinder, or the ram itself.

Ultimately, the contest between a hydraulic press and the object it crushes is a direct battle between two opposing structures, and the weaker one will always break.

Summary Table:

| Scenario | Why the Press Fails | Key Factor |

|---|---|---|

| Hardened Tool Steel Sphere | Force concentrates, ram deforms/shatters | Object geometry & hardness |

| Material Stronger Than Press Frame | Frame yields or fractures | Exceeds frame's tensile strength |

| Excessive System Pressure | Cylinder explodes violently | Surpasses cylinder burst pressure |

| Weakest Component Failure | Seals, hoses, or welds give way | Design limits of specific press model |

Need robust lab equipment that withstands extreme forces? KINTEK specializes in high-performance lab equipment and consumables designed for demanding applications. Whether you're testing material strength or require durable machinery for your laboratory, our solutions are engineered to exceed safety and performance standards. Contact us today to find the right equipment for your needs!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How is the pressure and temperature process used to make a synthetic diamond? Replicate Earth's Diamond Formation in a Lab

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density