At its core, safely applying pressure and vacuum to a system hinges on three principles: controlling the rate of change, preventing contamination, and ensuring the system is in a known, safe state before any intervention. Key precautions include using the correct, non-interchangeable pump oils, always closing the valve between the pump and the chamber before shutting the pump down, and slowly bleeding lines to equalize pressure before disconnecting any components.

The immense potential energy stored in a pressure differential, whether high pressure or a deep vacuum, is the primary hazard. Safe operation is not just about following rules, but about fundamentally respecting this energy and ensuring it is never released uncontrollably.

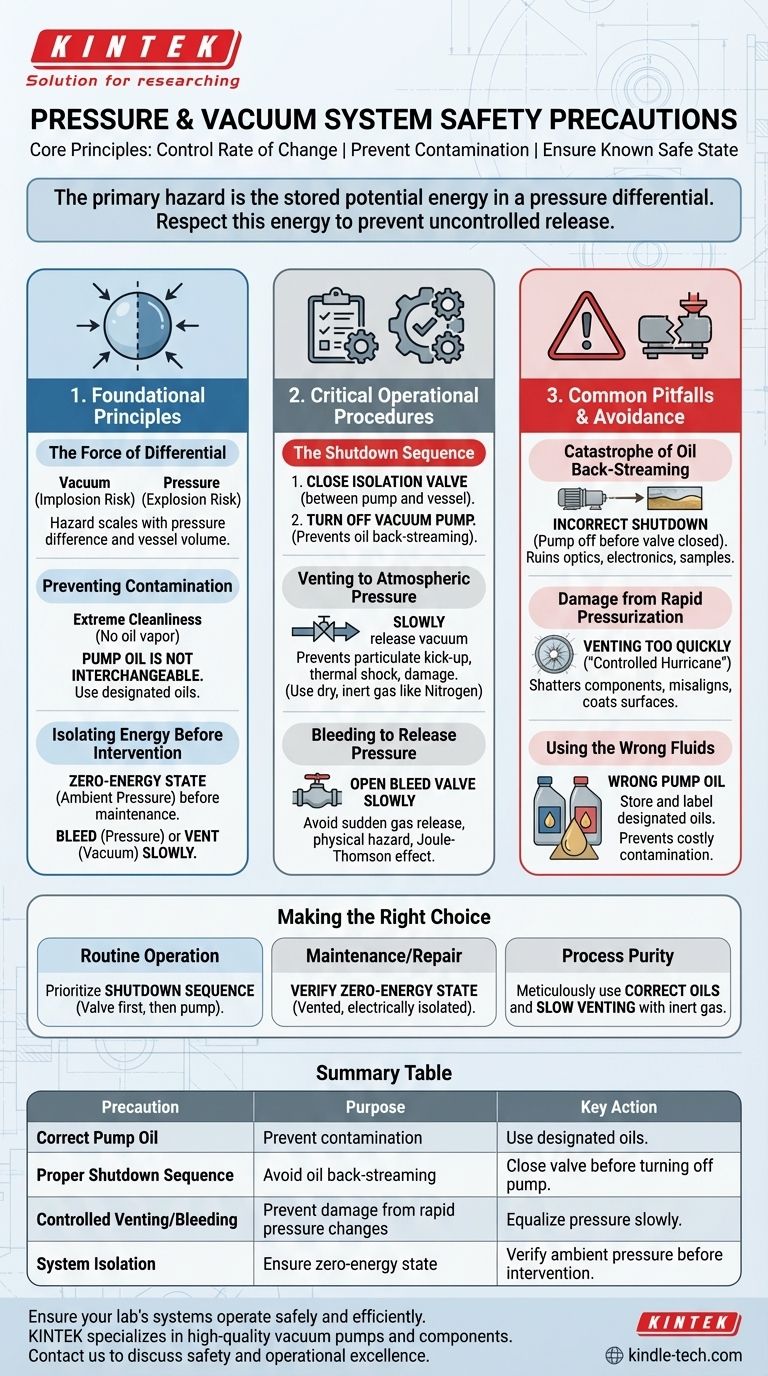

Foundational Principles of Vacuum and Pressure Safety

A vacuum does not "suck." Rather, the external atmospheric pressure, a force of approximately 14.7 pounds per square inch (or 101 kPa), pushes inward on the walls of a vessel. Understanding this principle is the first step to safe handling.

The Force of a Pressure Differential

A vacuum chamber is a stored-energy device. The larger the surface area, the greater the total inward force, creating a significant risk of implosion if the vessel is compromised.

Conversely, a pressurized system stores energy riscopposite way, posing an explosion risk. In both cases, the hazard级别scales with the pressure difference and the volume of the vessel.

Preventing System Contamination

Many high-vacuum applications require extreme cleanliness. The most common contaminant is oil vapor from the vacuum pumps themselves.

This is why pump oil is not interchangeable. A roughing pump oil has different vapor pressure characteristics than oil for a diffusion or booster pump. Using the wrong oil can contaminate the entire system, rendering it useless for它的intended purpose.

Proper shutdown procedures, such as closing isolation valves, are critical to prevent oil from back-streaming from the pump into the chamber.

Isolating Energy Before Intervention

Never work on a system that is under pressure or vacuum. The system must be returned to a zero-energy state—at ambient atmospheric pressure—before maintenance.

This is achieved by bleeding (for pressurized systems) or venting (for vacuum systems). This process must be slow and controlled.

Critical Operational Procedures

Following a strict, logical sequence of operations is non-negotiable. These procedures are designed to manage the stored energy and prevent contamination.

The Shutdown Sequence

The single most important sequence is shutting down a vacuum system. Failing to do this correctly is a common and costly mistake.

- Close the isolation valve between the vacuum pump and the vacuum vessel.

- Turn off the vacuum pump.

Following this order prevents the pressure difference from pushing oil from the pump back into your clean chamber.

Venting to Atmospheric Pressure

When you need to open the system, you must release the vacuum by venting it. This should always be done slowly.

A rapid in-rush of air can create turbulence that kicks up particulate contaminants, cause thermal shock to sensitive components, and even damage delicate internal-mechanisms. Often, a dry, inert gas like nitrogen is used for venting to avoid introducing moisture and oxygen.

Bleeding to Release Pressure

Similarly, when de-pressurizing a system, the bleed valve should be opened slowly. A sudden release of high-pressure gas can create a physical hazard, damage gauges, and cause extreme temperature drops due to the Joule-Thomson effect.

Common Pitfalls and How to Avoid Them

Mistakes in vacuum and pressure handling often stem from a misunderstanding of the underlying physics, leading to damaged equipment or contaminated processes.

The Catastrophe of Oil Back-Streaming

This occurs when the shutdown sequence is performed incorrectly. If the pump is turned off while still connected to the chamber, air from the pump's exhaust can push the pump oil backward, up into the vacuum lines and the chamber.

This can ruin sensitive optics, electronic components, or scientific samples, often requiring a complete and expensive system disassembly and cleaning.

Damage from Rapid Pressurization

Venting a vacuum chamber too quickly is like letting a controlled hurricane loose inside. The sudden blast of air can shatter delicate viewports, misalign internal fixtures, and coat every surface with any microscopic dust that was previously settled.

Using the Wrong Fluids

As stated in the operational principles, pump oils are highly specific. Always store and label oils for their designated pump. Educate all personnel on this fact. This simple discipline prevents costly contamination events.

Making the Right Choice for Your Task

Your specific task dictates which precautions are most critical at that moment.

- If your primary focus is routine operation: Always prioritize the shutdown sequence—close the isolation valve before turning off the pump.

- If your primary focus is maintenance or repair: Your absolute priority is to verify the system is fully vented to atmospheric pressure and electrically isolated before touching any hardware.

- If your primary focus is process purity: Meticulously use the correct pump oils and implement a slow, controlled venting procedure, preferably with a clean, dry inert gas.

Ultimately, a deep respect for pressure differentials is the foundation of safe and effective system operation.

Summary Table:

| Precaution | Purpose | Key Action |

|---|---|---|

| Correct Pump Oil | Prevent system contamination | Use designated, non-interchangeable oils |

| Proper Shutdown Sequence | Avoid oil back-streaming | Close isolation valve before turning off pump |

| Controlled Venting/Bleeding | Prevent damage from rapid pressure changes | Equalize pressure slowly before opening system |

| System Isolation | Ensure zero-energy state for maintenance | Verify ambient pressure before intervention |

Ensure your lab's pressure and vacuum systems operate safely and efficiently. KINTEK specializes in high-quality lab equipment and consumables, including vacuum pumps and system components designed for reliable, contamination-free performance. Our experts can help you select the right equipment and establish proper safety protocols for your specific laboratory needs. Contact us today to discuss how we can support your lab's safety and operational excellence!

Visual Guide

Related Products

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Laboratory High Pressure Vacuum Tube Furnace

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- What is the process of vacuum heat treating? Achieve Superior Hardening with a Clean, Bright Finish

- What temperature do you need to braze aluminum? Master the Precise 577-607°C Window for Strong Joints

- What can brazing be used to join? Unlock Versatile Metal & Ceramic Bonding Solutions

- What is the process of a pyrolysis furnace? Transform Waste into Valuable Products with Thermal Decomposition

- How does a vacuum diffusion bonding furnace contribute to titanium laminates? Precision for Near-Alpha Alloys

- What are the materials for vacuum hardening? A Guide to High-Performance Steel Selection

- What is the significance of using high-vacuum heat treatment furnaces and rapid quenching for zirconium alloys?

- What role does a high-temperature annealing furnace play in LPBF NAB? Optimize Microstructure for Industrial Performance