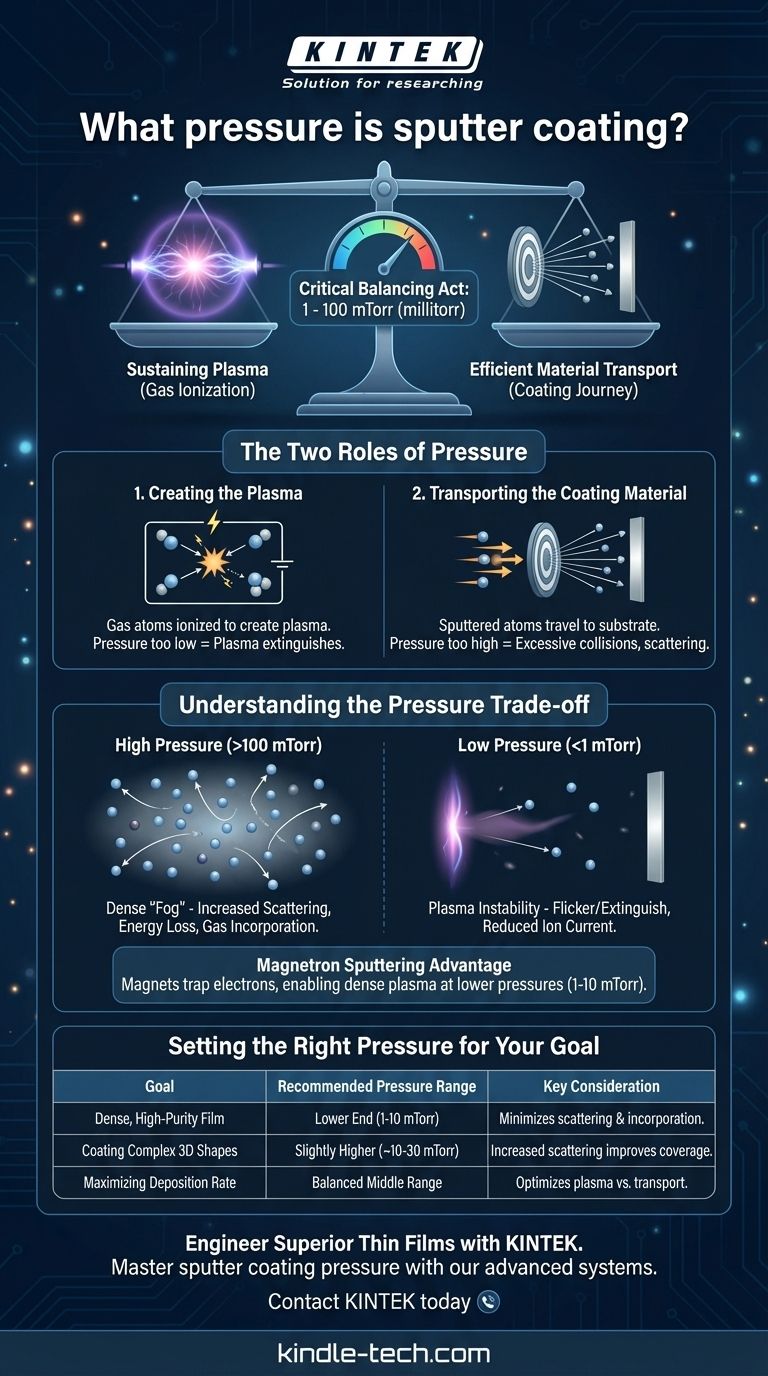

For effective sputter coating, the process is conducted in a vacuum with a carefully controlled gas pressure, typically in the range of 1 to 100 millitorr (mTorr). This low pressure is not a single value but a critical balancing act. It must be high enough to sustain a plasma but low enough to allow the ejected coating material to travel to your sample without interference.

The core challenge of sputter coating is managing a fundamental conflict: the process requires a gas to create a plasma, but that same gas becomes an obstacle for the material being deposited. The optimal pressure is the "sweet spot" that best resolves this conflict for a specific application.

The Two Roles of Pressure in Sputtering

To understand why a specific pressure is used, you must recognize its dual function in the sputtering process. The working gas, almost always a noble gas like Argon, plays two very different roles.

1. Creating the Plasma

Sputtering begins by introducing a small amount of working gas into a vacuum chamber. A high voltage is then applied, which strips electrons from the gas atoms, creating a mixture of positive ions and free electrons known as a plasma.

This process requires a minimum number of gas atoms. If the pressure is too low, there aren't enough atoms to collide with and sustain the ionization, and the plasma will extinguish.

2. Transporting the Coating Material

Once the plasma is formed, the positive gas ions (e.g., Ar+) are accelerated into the "target," which is a solid block of the material you want to deposit. These energetic ion collisions physically eject or "sputter" atoms from the target.

These sputtered atoms must then travel through the chamber and land on your sample (the "substrate"). This journey needs to be as direct as possible. If the gas pressure is too high, the sputtered atoms will constantly collide with gas atoms, scattering them and preventing them from reaching the substrate efficiently.

Understanding the Pressure Trade-off

The quality of your final coating is dictated by how well you manage the trade-off between sustaining the plasma and ensuring efficient material transport.

The Problem with High Pressure

When the pressure is too high (e.g., >100 mTorr), you create a dense "fog" of gas atoms. This leads to several negative effects:

- Increased Scattering: Sputtered atoms are deflected from their path, reducing the number of atoms that reach the substrate and slowing down the coating rate.

- Energy Loss: Collisions rob the sputtered atoms of their kinetic energy. Atoms arriving with low energy produce a less dense, more porous film with poorer adhesion.

- Gas Incorporation: Working gas atoms can become trapped in the growing film, altering its purity, stress, and electrical properties.

The Problem with Low Pressure

When the pressure is too low (e.g., <1 mTorr), the primary issue is sustaining the plasma itself.

- Plasma Instability: There are too few gas atoms to ensure a stable rate of ionization. It becomes difficult to ignite the plasma, and it may flicker or extinguish entirely.

- Reduced Ion Current: A weaker plasma means fewer ions are available to bombard the target, which directly reduces the sputtering rate.

Modern systems, particularly magnetron sputtering systems, use powerful magnets behind the target. These magnets trap electrons near the target surface, dramatically increasing their chances of ionizing a gas atom. This efficiency allows magnetrons to sustain a dense plasma at much lower pressures (typically 1-10 mTorr), which is a key reason for their widespread use.

Setting the Right Pressure for Your Goal

The ideal pressure depends entirely on your desired outcome. There is no single "best" pressure, only the right pressure for your specific objective.

- If your primary focus is a dense, high-purity film: Operate at the lowest stable pressure your system allows to minimize gas scattering and incorporation.

- If your primary focus is coating a complex 3D shape: A slightly higher pressure can be beneficial, as the increased scattering helps "throw" the coating material into shadowed areas, improving coverage uniformity.

- If your primary focus is maximizing the deposition rate: You must find the point where the plasma is strong but the pressure is low enough that scattering does not significantly impede material transport.

Mastering pressure control is the key to moving from simply applying a coating to engineering a film with specific, predictable properties.

Summary Table:

| Goal | Recommended Pressure Range | Key Consideration |

|---|---|---|

| Dense, High-Purity Film | Lower End (1-10 mTorr) | Minimizes gas scattering and incorporation for superior film properties. |

| Coating Complex 3D Shapes | Slightly Higher (~10-30 mTorr) | Increased scattering improves coverage in shadowed areas. |

| Maximizing Deposition Rate | Balanced Middle Range | Optimizes plasma strength while minimizing transport interference. |

Engineer Superior Thin Films with KINTEK

Mastering sputter coating pressure is essential for achieving the specific film properties your research demands. Whether you need dense, high-purity layers or uniform coverage on complex geometries, the right equipment is critical.

At KINTEK, we specialize in advanced lab equipment, including magnetron sputtering systems designed for precise pressure control. Our solutions help you consistently hit the 'sweet spot' for your unique applications, ensuring repeatable, high-quality results.

Ready to optimize your deposition process? Let our experts help you select the perfect system for your laboratory's needs.

Contact KINTEK today to discuss your project and discover how our sputtering solutions can enhance your work.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Non Consumable Vacuum Arc Induction Melting Furnace

People Also Ask

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings