In short, press forging is used to manufacture large, high-strength, and critical components where structural integrity is paramount. Key examples include aircraft landing gear, turbine disks for jet engines, automotive crankshafts, large industrial gears, and high-pressure valve bodies used in the energy sector.

Press forging is not defined by a single product but by a class of them: large-scale components requiring exceptional strength and internal quality. The process's slow, controlled pressure uniformly refines the metal's internal grain structure, making it the superior choice for parts that simply cannot fail.

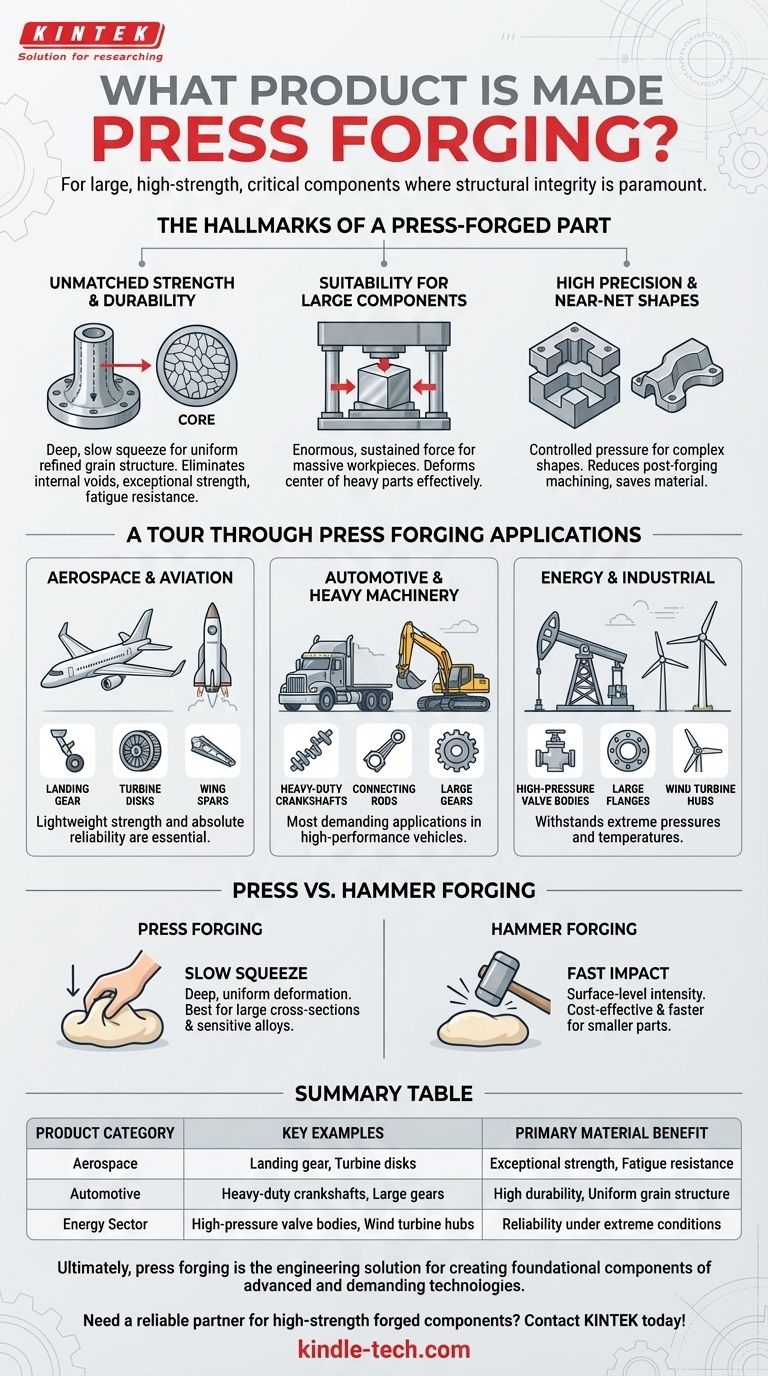

The Hallmarks of a Press-Forged Part

To understand why certain products are press-forged, you must first understand the unique characteristics the process imparts to the metal. It’s chosen when the performance requirements justify its cost.

Unmatched Strength and Durability

Press forging involves slowly applying immense, continuous pressure to a heated metal billet. This slow squeeze penetrates deep into the material's core.

The result is a highly refined and uniform grain structure throughout the entire part, eliminating internal voids and aligning the grain flow with the part's shape. This creates exceptional strength, ductility, and resistance to fatigue.

Suitability for Large Components

Hydraulic and mechanical presses can generate enormous, sustained force, making them ideal for shaping massive workpieces that can weigh many tons.

This is a key differentiator from hammer forging, which relies on the kinetic energy of a falling ram and is less effective at deforming the center of very large metal blocks.

High Precision and Near-Net Shapes

The controlled nature of the press allows for more complex die shapes and better dimensional accuracy than the violent impacts of hammer forging.

This reduces the amount of post-forging machining required, saving time and material, which is especially important when working with expensive alloys like titanium or nickel-based superalloys.

A Tour Through Press Forging Applications

The unique benefits of press forging make it indispensable in several high-stakes industries. The common thread is the need for large components with superior mechanical properties.

Aerospace and Aviation

This is the classic domain for press forging. The need for lightweight strength and absolute reliability makes it essential.

Products include structural airframe bulkheads, landing gear components, turbine and compressor disks for jet engines, and wing spars.

Automotive and Heavy Machinery

While many smaller automotive parts are drop-forged, press forging is used for the most demanding applications in high-performance vehicles and heavy equipment.

Examples are heavy-duty crankshafts, connecting rods, large gears for transmissions, and front axles for trucks and earthmovers.

Energy and Industrial

In the oil, gas, and power generation industries, components must withstand extreme pressures and temperatures.

Press forging is used to create large valve bodies, high-pressure flanges, hubs for wind turbines, and components for nuclear reactors.

Understanding the Trade-offs: Press vs. Hammer Forging

Choosing a forging process is an engineering and economic decision. Press forging is powerful but not always the right tool for every job.

The Core Difference: Slow Squeeze vs. Fast Impact

Think of press forging as slowly kneading dough to work it all the way through. Hammer forging is like striking the dough with a mallet—the effect is intense but more localized to the surface.

The slow squeeze of press forging ensures deep, uniform deformation. The rapid impact of a hammer is excellent for shaping the surface and is often faster and less expensive for smaller components.

When to Choose Press Forging

This method is the superior choice when your design involves large cross-sections, requires uniform mechanical properties through its core, or is made from sensitive alloys (like titanium and nickel alloys) that can crack under the shock of hammer blows.

When Other Methods Are Better

For smaller parts where ultimate internal refinement is not the primary driver, hammer or drop forging is typically more cost-effective and faster. Many standard automotive components, hand tools, and fittings are made this way.

Making the Right Choice for Your Goal

The decision to use press forging comes down to balancing performance requirements with manufacturing costs.

- If your primary focus is maximum strength for large, critical components: Press forging is the definitive choice due to its deep, uniform material deformation.

- If your primary focus is cost-effective production for smaller parts: Hammer or drop forging often provides a better balance of performance and cost.

- If your primary focus is working with high-performance or sensitive alloys: The controlled pressure of press forging minimizes the risk of material cracking.

Ultimately, press forging is the engineering solution for creating the foundational components of our most advanced and demanding technologies.

Summary Table:

| Product Category | Key Examples | Primary Material Benefit |

|---|---|---|

| Aerospace | Landing gear, turbine disks, wing spars | Exceptional strength, fatigue resistance |

| Automotive | Heavy-duty crankshafts, connecting rods, large gears | High durability, uniform grain structure |

| Energy Sector | High-pressure valve bodies, flanges, wind turbine hubs | Reliability under extreme pressures and temperatures |

Need a reliable partner for high-strength forged components? KINTEK specializes in providing precision lab equipment and consumables, serving industries that demand uncompromising quality and performance. Whether you're in aerospace, automotive, or energy, our expertise ensures your components meet the highest standards of durability and precision. Contact us today to discuss how we can support your manufacturing goals with tailored solutions!

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does the use of a high-pressure uniaxial hydraulic press influence the final phase structure? Optimize Conductivity

- What materials are used in press forming? Choosing the Right Metal for Your Stamped Parts

- Do hydraulic presses use electricity? Powering Industrial Force with Electric Motors

- What core conditions does a laboratory hydraulic press provide for solid-state electrolyte pellets? Enhance Density!

- What are the hazards of press machine? Mitigate Crushing, Amputation, and Other Critical Risks

- Why is a uniaxial hydraulic press used for LLZTO powder? Achieving High Green Density for Ceramic Success

- What is the difference between XRF and AAS? Choosing the Right Elemental Analysis Tool

- Why is a laboratory hydraulic press required for solid-state battery assembly? Essential Tools for Ion Conductivity