In practice, "surface hardening" refers not to a single off-the-shelf product, but to a range of industrial processes that modify the surface of a metal part. These processes use specific materials like carbon-rich gases, nitrogen-releasing salts, or applied energy sources like induction coils to create a hard, wear-resistant outer layer while preserving a softer, tougher core.

The most critical takeaway is that choosing a surface hardening "product" is actually about selecting a process. The right choice depends entirely on the base material, the desired surface properties (like wear resistance), and the part's geometry and application.

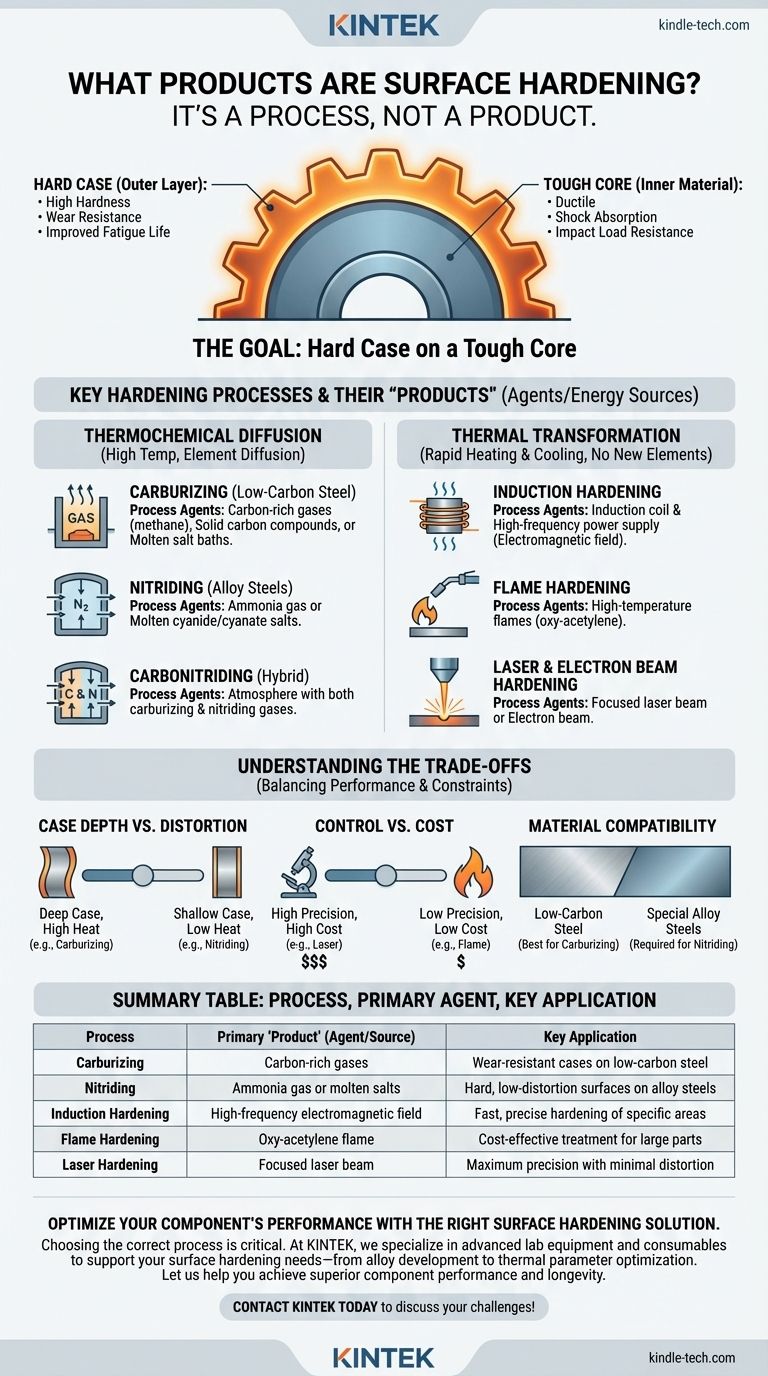

The Goal: Creating a Hard Case on a Tough Core

Surface hardening, also known as case hardening, is a fundamental metallurgical strategy. It aims to create a component with two distinct sets of properties.

The "Case" (Outer Layer)

The hardened surface, or case, provides high hardness. This is essential for components that experience friction, abrasion, or contact stress. A hard case delivers exceptional wear resistance and can improve fatigue life.

The "Core" (Inner Material)

The original, untreated interior of the material, or core, remains relatively soft and ductile. This toughness allows the component to absorb shock and impact loads without fracturing, a property a fully hardened part would lack.

Key Hardening Processes and Their "Products"

The "products" involved in surface hardening are the agents or energy sources used in a specific process. They can be broadly categorized into thermochemical, thermal, and mechanical methods.

Thermochemical Diffusion Processes

These processes work by diffusing elements into the surface of the steel at high temperatures.

Carburizing

Carburizing introduces carbon into the surface of low-carbon steel. The part is then quenched to create a high-carbon, hardened martensitic case.

- Process Agents ("Products"): Carbon-rich atmospheres (gas carburizing using gases like methane or propane), solid carbon-based compounds (pack carburizing), or cyanide-based molten salt baths (liquid carburizing).

Nitriding

Nitriding diffuses nitrogen into the surface of special alloy steels containing nitride-forming elements like aluminum or chromium. It is a lower-temperature process that causes minimal distortion.

- Process Agents ("Products"): Ammonia gas (gas nitriding) or molten cyanide and cyanate salts (salt bath nitriding).

Carbonitriding

This process is a hybrid, diffusing both carbon and nitrogen into the steel's surface. It creates a harder case than carburizing alone and can be performed at lower temperatures.

- Process Agents ("Products"): An atmosphere containing both a carburizing gas (like propane) and a nitriding gas (ammonia).

Thermal Transformation Processes

These methods use rapid heating and cooling of the surface to transform its structure without adding new elements.

Induction Hardening

A high-frequency alternating current is passed through a copper coil, inducing eddy currents that rapidly heat the part's surface. Once the critical temperature is reached, it is immediately quenched.

- Process Agents ("Products"): An induction coil and a high-frequency power supply. The "product" is the precisely controlled electromagnetic field.

Flame Hardening

This is a similar concept to induction hardening but uses a direct flame to heat the surface. It is less precise but often more cost-effective for very large parts or small-batch production.

- Process Agents ("Products"): High-temperature flames, typically from oxy-acetylene or other fuel gases.

Laser & Electron Beam Hardening

These advanced methods use a highly focused energy beam (laser or electron beam) to heat a very localized surface area with extreme precision. This offers maximum control and minimal distortion.

- Process Agents ("Products"): A focused laser beam or electron beam.

Understanding the Trade-offs

No single surface hardening process is universally superior. The choice involves balancing performance requirements with practical constraints.

Case Depth vs. Distortion

Processes like carburizing can produce very deep, robust cases (over 1mm) but require high heat, increasing the risk of part distortion. In contrast, nitriding is a lower-temperature process that produces a shallower but very hard case with minimal distortion, making it ideal for finished, close-tolerance parts.

Control vs. Cost

Laser hardening offers unparalleled control over which areas are hardened, but the equipment and processing costs are high. On the other end, flame hardening is inexpensive but offers far less precision. Induction hardening strikes a balance, offering excellent control and speed for high-volume production.

Material Compatibility

The base metal is a critical factor. Carburizing is designed for low-carbon steels. Nitriding, however, requires specific alloying elements (like Cr, Mo, Al, V) in the steel to be effective. Standard plain carbon steels cannot be effectively nitrided.

Selecting the Right Hardening Process

Your choice should be driven by the primary engineering goal for your component.

- If your primary focus is maximum wear resistance and hardness with minimal distortion: Gas nitriding is the superior choice, provided you are using a compatible alloy steel.

- If your primary focus is creating a deep, tough case for high-impact applications: Carburizing followed by quenching is the standard industry method for low-carbon steels.

- If your primary focus is high-volume, repeatable hardening of specific areas (like gear teeth or bearing journals): Induction hardening offers an unmatched combination of speed, control, and consistency.

- If your primary focus is low-cost hardening for large or simple parts: Flame hardening provides a practical and economical solution.

Ultimately, selecting the right surface treatment is a critical design decision that directly impacts the performance and lifespan of your component.

Summary Table:

| Process | Primary 'Product' (Agent/Source) | Key Application |

|---|---|---|

| Carburizing | Carbon-rich gases (e.g., methane) | Wear-resistant cases on low-carbon steel |

| Nitriding | Ammonia gas or molten salts | Hard, low-distortion surfaces on alloy steels |

| Induction Hardening | High-frequency electromagnetic field | Fast, precise hardening of specific areas |

| Flame Hardening | Oxy-acetylene flame | Cost-effective treatment for large parts |

| Laser Hardening | Focused laser beam | Maximum precision with minimal distortion |

Optimize Your Component's Performance with the Right Surface Hardening Solution

Choosing the correct surface hardening process is critical to enhancing wear resistance, fatigue life, and durability while maintaining a tough core. At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your surface hardening needs—whether you're developing new alloys, testing case depths, or optimizing thermal treatment parameters.

Our expertise supports laboratories and manufacturers in selecting and implementing the ideal hardening method for their specific materials and applications. Let us help you achieve superior component performance and longevity.

Contact KINTEK today to discuss your surface hardening challenges and explore our specialized solutions!

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- What are the environmental issues with biomass? The Hidden Costs of a 'Green' Energy Source

- What is a cheaper alternative to injection moulding? Find the Right Process for Your Volume

- What is a filter press used for? Achieve Maximum Solid-Liquid Separation Efficiency

- What temperature is brazing material? Master the Heat for Perfect Metal Joints

- What is the function of a laboratory heater? Achieve Precise, Safe, and Controlled Heating

- What is RF sputtering? A Guide to Depositing Non-Conductive Thin Films

- What are the techniques of sintering? Choose the Right Method for Your Material

- What data is collected for a melting point measurement? A Guide to Accurate Identity & Purity Analysis