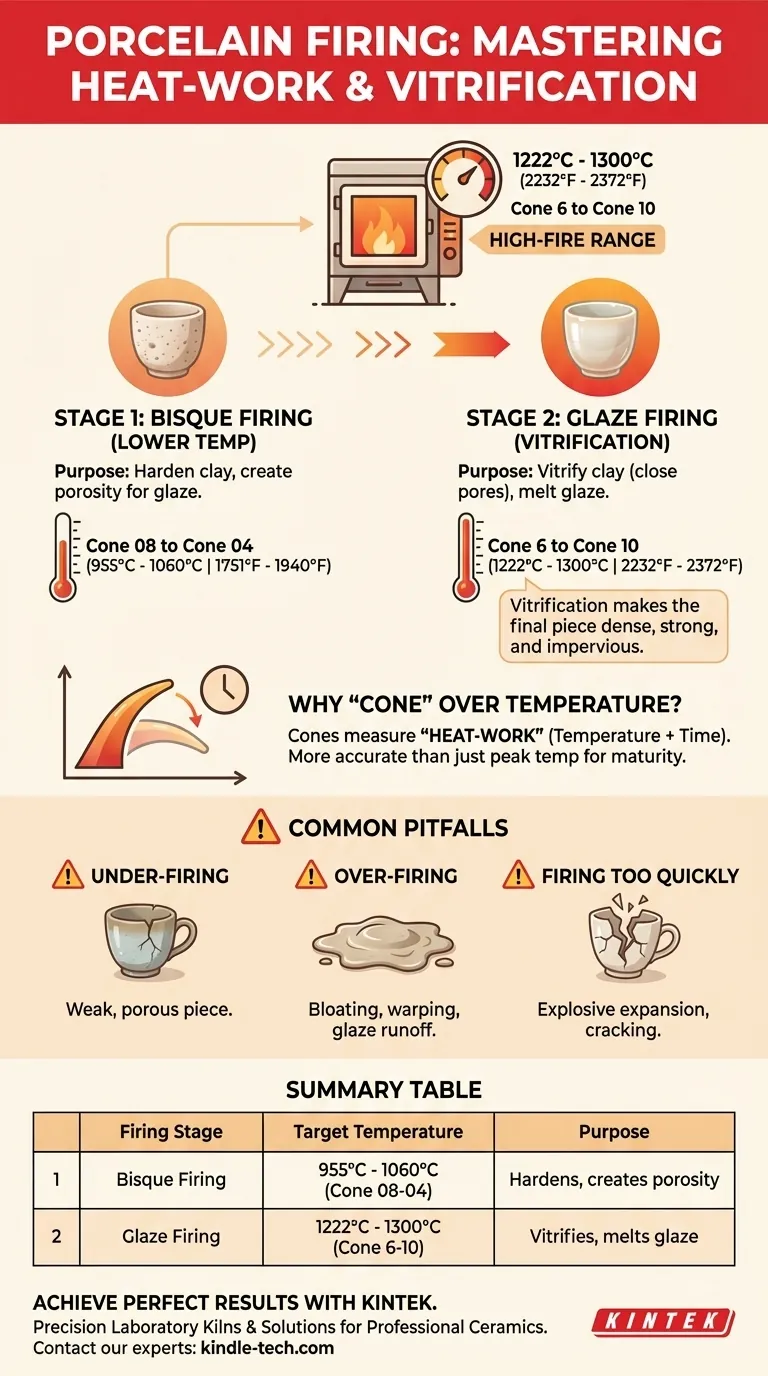

In professional ceramics, porcelain is typically high-fired to a temperature between 1222°C and 1300°C (2232°F and 2372°F). This range corresponds to the pyrometric cone standards of Cone 6 to Cone 10. However, this single number represents only the final step; the correct temperature is part of a larger, carefully controlled process that includes a preliminary "bisque" firing at a much lower temperature.

The specific temperature is less important than the entire firing schedule—the controlled rate of heating, holding, and cooling. True success with porcelain comes from understanding this complete process, as it is the total "heat-work" that determines the final properties of the piece.

The Two-Stage Firing Process Explained

Porcelain is almost never fired just once. Achieving its signature strength and translucency requires a two-step approach, with each stage serving a distinct purpose at a different temperature.

Stage 1: The Bisque Firing

The first firing, known as the bisque firing, is a lower-temperature step. Its goal is not to fully mature the clay but to transform it into a hardened, yet porous, ceramic state.

This porosity is critical because it allows the piece to readily absorb the water-based glaze in the next step without dissolving or breaking.

A typical porcelain bisque firing happens between Cone 08 and Cone 04, which is approximately 955°C to 1060°C (1751°F to 1940°F).

Stage 2: The Glaze Firing (Vitrification)

The second and final firing is the high-temperature glaze firing. This is where the porcelain reaches its peak temperature and undergoes vitrification.

Vitrification is the process where the clay particles melt and fuse together, closing the pores and making the final piece dense, strong, and impervious to water.

This is the firing that brings the piece to its final temperature of Cone 6 to Cone 10 (1222°C to 1300°C), melting the applied glaze into a smooth, glassy coating that bonds permanently to the clay body.

Why "Cone" is More Important Than Temperature

In ceramics, professionals rarely talk about temperature alone. Instead, they refer to pyrometric cones, which provide a more accurate measure of what happens inside a kiln.

What is a Pyrometric Cone?

A pyrometric cone is a small, pyramid-shaped tool made of ceramic materials. It is designed to soften and bend at a specific combination of temperature and time.

Measuring "Heat-Work," Not Just Heat

A kiln can reach a target temperature very quickly or very slowly. These two paths will produce dramatically different results in the clay, even if the peak temperature is identical.

Cones measure this total energy input, known as "heat-work." When the correct cone bends, it confirms the porcelain has absorbed the right amount of energy to mature properly, providing a more reliable outcome than a simple temperature reading.

Common Pitfalls to Avoid

The firing schedule is a precise formula. Deviating from the requirements of your specific clay body can easily ruin a piece.

The Risk of Under-firing

If the porcelain does not reach its required maturation temperature, it will not fully vitrify. The resulting piece will be weak, porous, and prone to breaking. The glaze may also appear dull, rough, or poorly fitted.

The Danger of Over-firing

Firing porcelain to a temperature higher than its intended cone rating is equally damaging. The clay body can bloat, warp, or even melt into a puddle on the kiln shelf. Glazes will become overly fluid, running off the piece and potentially damaging your equipment.

Firing Too Quickly

Ramping up the temperature too fast, especially during the early stages, can cause moisture trapped in the clay to turn to steam and expand explosively. This is a primary cause of cracking and shattering inside the kiln.

Making the Right Choice for Your Goal

Always match your firing program to your materials. There is no universal setting that works for all types of porcelain.

- If your primary focus is working with a commercial clay body: Always follow the manufacturer's recommended cone firing range. This information is non-negotiable and is printed on the packaging.

- If your primary focus is ensuring glaze compatibility: Make sure the cone rating of your glaze matches the cone rating of your porcelain clay body. A mismatch is a leading cause of defects like crazing (cracking) or shivering.

- If your primary focus is troubleshooting defects like warping: Your piece is likely being over-fired or is not adequately supported on the kiln shelf. Verify your target cone and consider a slower heating and cooling cycle.

Ultimately, mastering porcelain is about mastering the controlled application of heat over time.

Summary Table:

| Firing Stage | Target Temperature | Purpose |

|---|---|---|

| Bisque Firing | 955°C - 1060°C (Cone 08-04) | Hardens clay, creates porosity for glazing |

| Glaze Firing | 1222°C - 1300°C (Cone 6-10) | Vitrifies clay, melts glaze for final finish |

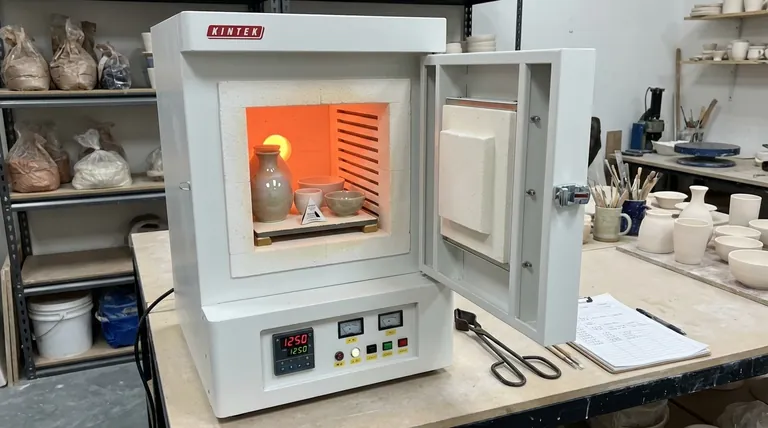

Achieve Perfect Porcelain Results with KINTEK

Mastering porcelain firing requires precision equipment and expert knowledge. At KINTEK, we specialize in high-performance laboratory kilns and consumables designed specifically for professional ceramics. Our reliable equipment ensures precise temperature control and consistent heat-work for perfect vitrification every time.

Let us help you unlock the full potential of your porcelain projects. Whether you're a studio artist, educational institution, or research facility, KINTEK has the solutions to support your ceramic firing needs.

Contact our experts today to discuss the ideal kiln for your porcelain workflow and achieve flawless results!

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the melting temperature of ceramics? Understanding High-Temperature Material Performance

- Does melting point ever change? Unlock the Secrets of Pressure and Purity

- How did the design of muffle furnaces change with the advent of electric heating elements? The Evolution to Precision and Purity

- What is the muffle furnace used for ash content? Achieve Accurate Gravimetric Analysis

- How is ash content determined using muffle furnace? Achieve Accurate Mineral Analysis