There is no single temperature for sintering. The process is not defined by an absolute number but is fundamentally relative to the specific material being consolidated. Sintering temperatures can range dramatically, from 630°C for certain alloys to over 2000°C for high-performance ceramics, with the critical requirement being that the temperature remains below the material's actual melting point.

The core principle of sintering is not to reach a specific temperature, but to apply enough thermal energy to allow atoms to diffuse across particle boundaries. This typically requires a temperature greater than 60% of the material's absolute melting temperature (Tm), but always below the point of liquefaction.

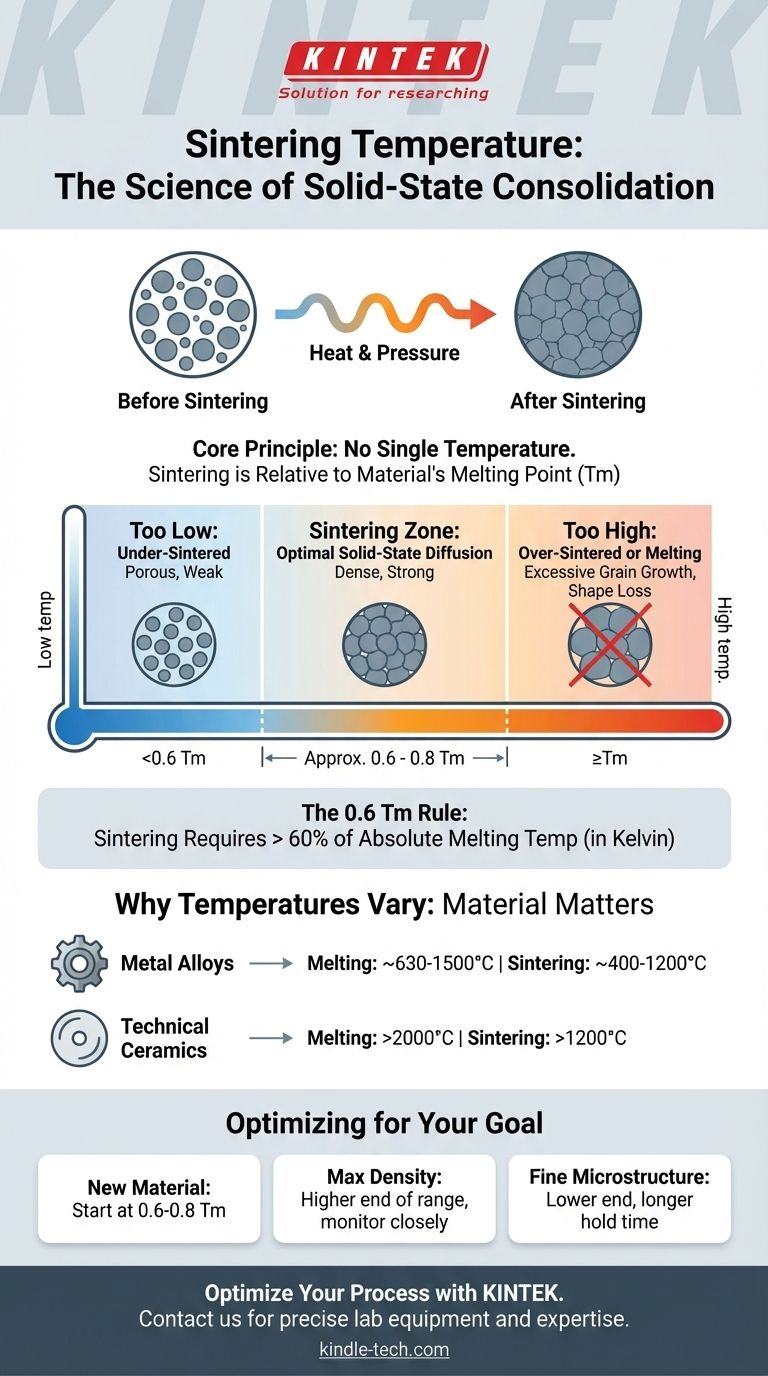

The Core Principle: Temperature's Role in Sintering

Sintering is a process of compaction and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction. Temperature is the primary driver of this transformation.

Facilitating Atomic Diffusion

The main purpose of heat in sintering is to give atoms enough energy to move. At high temperatures, atoms vibrate intensely and can diffuse across the boundaries of individual particles, filling the voids between them.

This atomic movement reduces the total surface area and causes the particles to fuse, creating a dense, coherent solid piece from a starting powder.

The "Goldilocks" Zone: Below the Melting Point

It is critical to understand that sintering is a solid-state process. The goal is to make the material hot enough for atoms to move, but not so hot that the material's crystalline structure collapses.

If the temperature reaches or exceeds the melting point, the process is no longer sintering; it becomes casting or welding, and the precise shape of the compacted powder is lost.

The 0.6 Tm Rule of Thumb

As a general guideline, the minimum temperature for effective sintering is often cited as being greater than 0.6 times the material's absolute melting temperature (Tm).

For this rule to be accurate, the temperature must be calculated in Kelvin. For example, a material melting at 1727°C (2000 K) would begin to sinter effectively around 927°C (1200 K).

Why Sintering Temperatures Vary So Widely

The vast range in sintering temperatures is a direct result of the different properties of the materials being processed. The 2000°C and 630°C figures are both correct—just for entirely different substances.

Material Melting Point

This is the single most important factor. A material with a very high melting point, like a technical ceramic, will naturally require a very high sintering temperature.

Conversely, a metal alloy with a lower melting point will sinter at a correspondingly lower temperature. The sintering temperature scales directly with the melting point.

Pre-Sintering Processes

In many industrial applications, especially in metal injection molding (MIM) and ceramics, a preliminary step called debinding occurs before sintering.

This process happens at a much lower temperature (e.g., up to 600°C) and serves to burn away a polymer binder that holds the powder in its green state. This must be done completely before ramping up to the much higher sintering temperature.

Understanding the Trade-offs

Choosing a sintering temperature is a balance. The precise temperature and duration affect the final properties of the part, and getting it wrong can lead to component failure.

Under-Sintering: Insufficient Temperature

If the temperature is too low or the time too short, atomic diffusion will be incomplete. This results in a weak, porous part that has not achieved full density, compromising its mechanical strength and other properties.

Over-Sintering: Excessive Grain Growth

If the temperature is too high (while still below melting), the process can happen too quickly or aggressively. This leads to excessive grain growth, where smaller crystal grains merge into larger ones. While the part may be dense, large grains can often make the material more brittle.

The Danger of Melting

Exceeding the melting point is a catastrophic failure in the sintering process. The part will slump, lose its shape, and its internal microstructure will be destroyed, rendering it useless.

Determining the Right Temperature for Your Project

The ideal sintering temperature is not a fixed number but a variable you control to achieve a desired outcome. Your focus should be on the material's properties and your end goal.

- If your primary focus is working with a new material: Start by finding its melting temperature (Tm) and use the range of 0.6 to 0.8 Tm (in Kelvin) as your experimental starting point.

- If your primary focus is achieving maximum density: You will likely need to operate at the higher end of the material's sintering range, carefully monitoring to avoid excessive grain growth or melting.

- If your primary focus is preserving a fine-grained microstructure for specific properties: Aim for the lower end of the effective sintering temperature range, potentially combined with a longer hold time to achieve sufficient density.

Ultimately, understanding that sintering temperature is a function of a material's intrinsic properties empowers you to move beyond searching for a single number and toward optimizing the process for your specific goal.

Summary Table:

| Material Type | Typical Melting Point (Tm) Range | Sintering Temperature Range (Approx. 0.6-0.8 Tm) |

|---|---|---|

| Metal Alloys | ~630°C - 1500°C | ~400°C - 1200°C |

| Technical Ceramics | >2000°C | >1200°C |

| General Guideline | Varies by Material | Always below melting point |

Optimize your sintering process with KINTEK's expertise.

Whether you're working with high-performance ceramics or specialized metal alloys, achieving the perfect sintering temperature is critical for part density, strength, and microstructure. KINTEK specializes in providing the precise lab equipment and consumables you need to control your thermal processes effectively.

Let our experts help you select the right furnace and accessories to ensure your materials sinter correctly, without under-sintering or excessive grain growth.

Contact our team today to discuss your specific material and application requirements. We'll help you move beyond guesswork and achieve consistent, high-quality results.

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What is the difference between hot air oven and laboratory incubator? Choose the Right Thermal Instrument

- What metals can you braze together? A Guide to Strong, Versatile Metal Joining

- What is the future of pyrolysis oil? A Key to Circular Economy & Renewable Fuels

- How to do brazing on stainless steel? Master the Art of Overcoming the Oxide Layer for Strong, Permanent Bonds

- What is the technical advantage of using an ammonia and hydrogen gas mixture? Achieve Precision Surface Engineering

- What happens to metal powders during sintering? Transform Powder into Durable, Complex Metal Parts

- What role does an alumina-supported substrate play in CCD? Unlock the 'Gate' Effect for MFI Zeolite Membranes

- Which type of water should be used in water bath for laboratory? Protect Your Equipment and Experiments