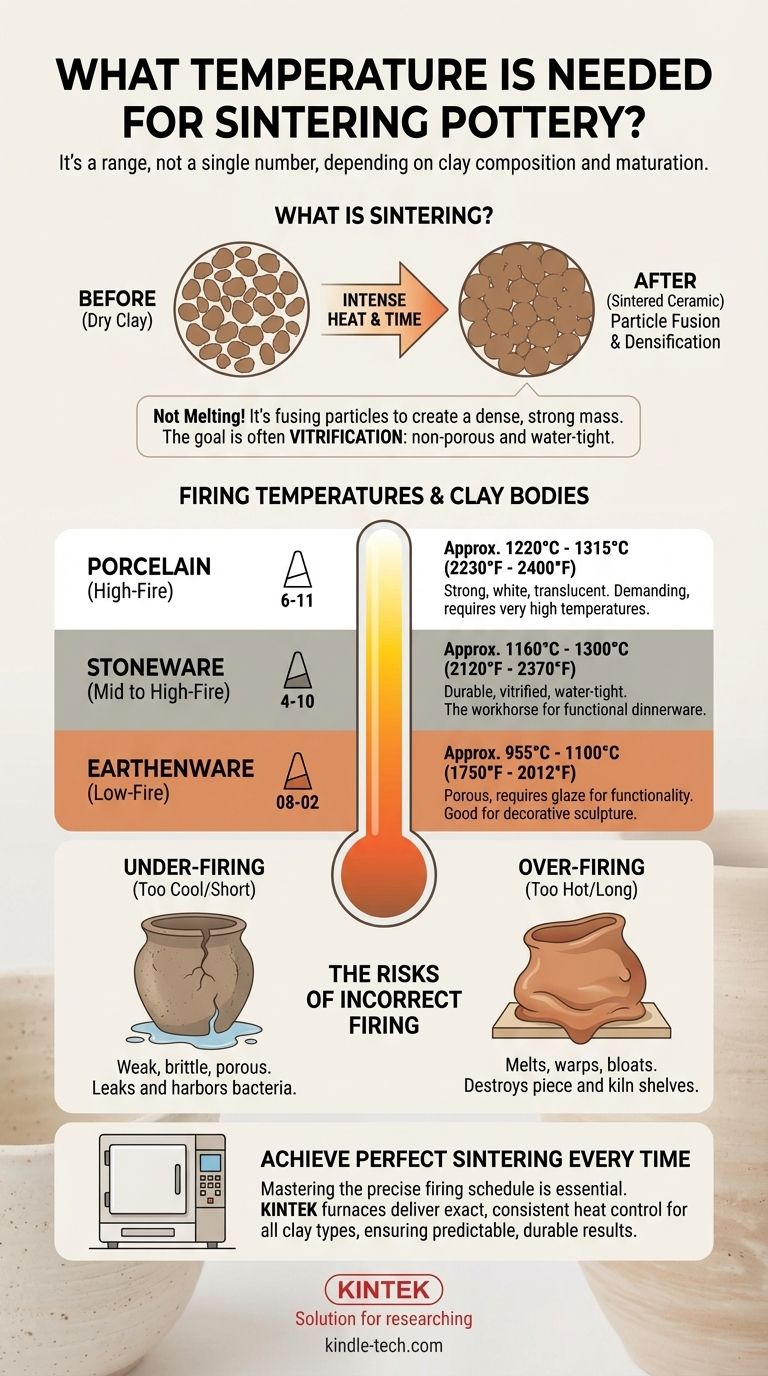

The temperature required for sintering pottery is not a single number, but a wide range that depends entirely on the chemical composition of the clay body you are using. Generally, this process occurs between 955°C (1750°F) for low-fire earthenware and can go as high as 1300°C (2370°F) for high-fire porcelain. The key is to fire the clay to its specific maturation point to achieve the desired strength and density.

Sintering is a process of particle fusion driven by heat, not just a target temperature. The fundamental task for any potter is to match the firing schedule—specifically the target "cone"—to their specific clay body. This ensures the piece becomes strong and dense without melting or warping.

What is Sintering in Ceramics?

Sintering is the critical transformation that turns a fragile, chalky piece of dry clay into a hard, stone-like ceramic object. Understanding this process is more important than memorizing a single temperature.

From Particles to a Solid Mass

At a microscopic level, clay is made of tiny, flat particles. During sintering, the intense heat causes the edges of these particles to fuse together. The particles themselves don't melt entirely, but they bond at their points of contact, reducing the space between them and creating a dense, unified mass.

Sintering vs. Melting

This is a crucial distinction. Sintering is the fusion of particles without turning the entire object into a liquid. If you exceed the correct sintering range, the clay will begin to fully melt, a process called slumping or bloating, which results in a ruined piece.

The Goal: Vitrification

For functional pottery like mugs or bowls, the ideal result of sintering is vitrification. This is a state where the clay particles have fused so densely that the final object is no longer porous and will not absorb water. Low-fire clays sinter but do not fully vitrify, remaining porous unless covered in a glaze.

Firing Temperatures for Common Clay Bodies

The ceramic world categorizes clay by the temperature required to bring it to maturity. This is most accurately measured using a system of pyrometric cones, which bend at a specific "heat work" value—a combination of time and temperature.

Earthenware (Low-Fire)

Earthenware is fired at the lowest temperatures. It sinters to become hard but remains porous, making it unsuitable for functional dinnerware unless properly glazed.

- Cone Range: Cone 08 to Cone 02

- Temperature Range: Approx. 955°C to 1100°C (1750°F to 2012°F)

Stoneware (Mid to High-Fire)

Stoneware is the workhorse of functional pottery. When fired correctly, it becomes vitrified, making it extremely durable, strong, and water-tight. It has a broad firing range depending on the specific clay body.

- Cone Range: Cone 4 to Cone 10

- Temperature Range: Approx. 1160°C to 1300°C (2120°F to 2370°F)

Porcelain (High-Fire)

Porcelain is known for its strength, whiteness, and potential for translucency. It is a demanding clay body that must be fired at very high temperatures to achieve its signature vitrified state.

- Cone Range: Cone 6 to Cone 11

- Temperature Range: Approx. 1220°C to 1315°C (2230°F to 2400°F)

Understanding the Trade-offs: Under-firing vs. Over-firing

Achieving the correct level of sintering is a balancing act. Errors in either direction will compromise your final result.

The Risks of Under-firing

An under-fired piece has not sintered sufficiently. The clay particles have not fused together properly, resulting in a piece that is weak, brittle, and porous. For functional ware, this means it will leak and can harbor bacteria.

The Dangers of Over-firing

An over-fired piece has been heated beyond its maturation point. The clay begins to melt, causing it to bloat, warp, and slump into a puddle. In a worst-case scenario, it can melt onto and destroy your kiln shelves, a costly and frustrating mistake.

Making the Right Choice for Your Goal

Your firing strategy should always be dictated by your clay choice and the intended use of the final piece.

- If your primary focus is functional dinnerware: You must fire to the clay's specified maturation point (typically mid-to-high fire stoneware or porcelain) to ensure it is fully vitrified and food-safe.

- If your primary focus is decorative sculpture: You have more flexibility. Low-fire earthenware is an excellent choice that offers vibrant glaze colors and requires less energy to fire.

- If you are ever unsure about your clay: Always trust the manufacturer's recommendation. The clay's packaging will state the ideal firing cone, which is the most reliable guide for achieving proper sintering.

Matching your firing process to your specific clay body is the fundamental skill for achieving predictable and durable ceramic results.

Summary Table:

| Clay Body Type | Firing Range (Cone) | Temperature Range (°C) | Temperature Range (°F) | Key Characteristic |

|---|---|---|---|---|

| Earthenware (Low-Fire) | Cone 08 - Cone 02 | 955°C - 1100°C | 1750°F - 2012°F | Porous, requires glaze for functionality |

| Stoneware (Mid to High-Fire) | Cone 4 - Cone 10 | 1160°C - 1300°C | 2120°F - 2370°F | Durable, vitrified, and water-tight |

| Porcelain (High-Fire) | Cone 6 - Cone 11 | 1220°C - 1315°C | 2230°F - 2400°F | Strong, white, and potentially translucent |

Achieve Perfect Sintering Every Time with KINTEK

Mastering the precise temperature for your clay body is essential for creating strong, functional, and beautiful pottery. KINTEK specializes in providing reliable lab furnaces and kilns that deliver the exact, consistent heat control needed for perfect sintering results—from low-fire earthenware to high-fire porcelain.

Our equipment helps you avoid the risks of under-firing (weak, porous pieces) and over-firing (warping, melting), ensuring your ceramics reach their full potential. Whether you're a studio artist, educator, or professional potter, we have the solutions to meet your specific firing needs.

Ready to elevate your ceramic work? Contact our experts today to find the ideal kiln for your studio and achieve predictable, durable results with every firing.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the suitable material of construction of a muffle furnace? A Guide to High-Temperature Performance

- What is the purpose of using a high-temperature muffle furnace for 500 °C calcination? Optimize Catalyst Activity

- What contributes to ash content in food? A Guide to Mineral Content and Food Quality

- What is a muffle furnace in the food industry? A Key Tool for Accurate Nutritional Analysis

- What role does a box resistance furnace play in solar-thermal wood treatment? Unlock High-Efficiency Light Absorption

- What role does a high-temperature calcination furnace play in the synthesis of mixed metal oxide catalysts?

- Why is a high-temperature muffle furnace required for the pre-treatment of catalyst supports? Engineering Performance

- What is firing and sintering? A Guide to the Powder-to-Solid Transformation