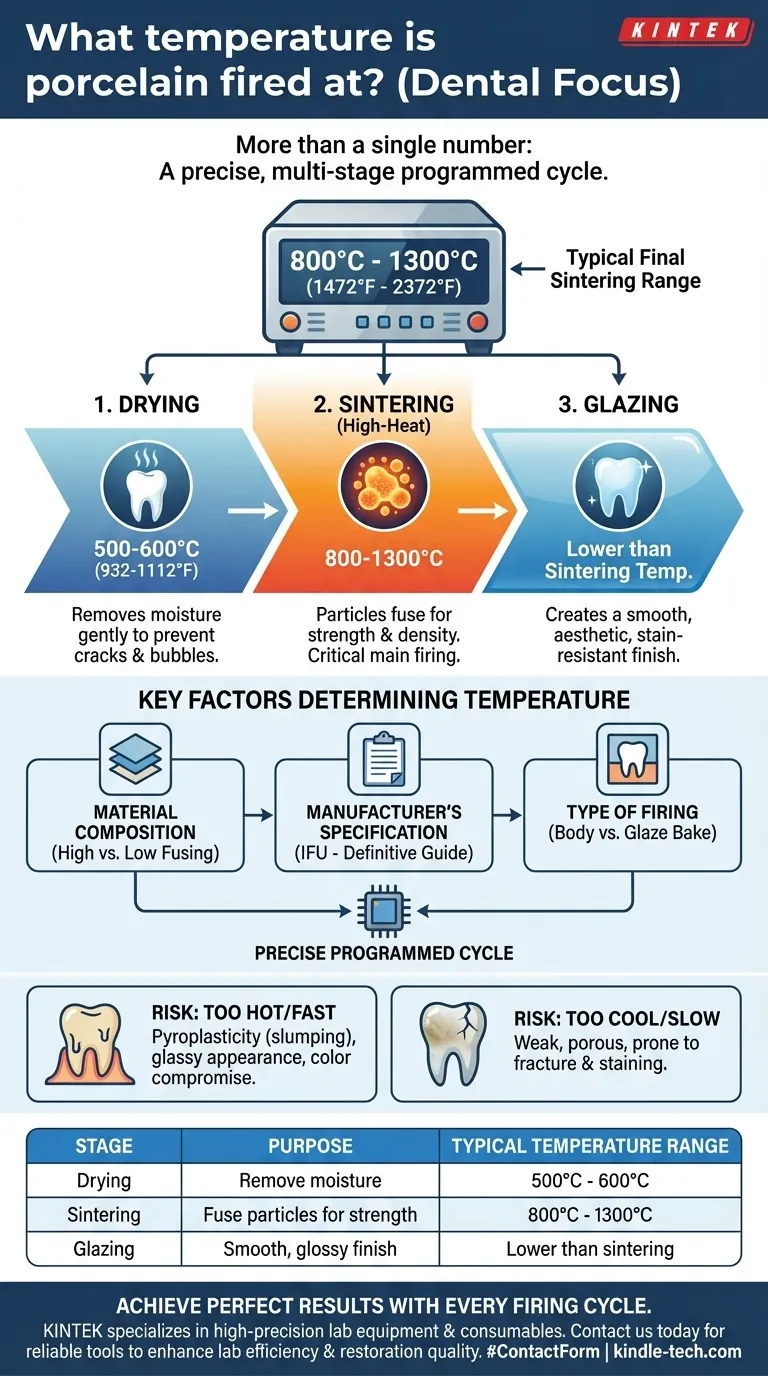

The final firing temperature for dental porcelain typically falls between 800°C and 1300°C (1472°F to 2372°F). However, a single number is misleading because porcelain firing is not one event but a precise, multi-stage process where temperature, duration, and rate of heating are all critical variables.

The crucial insight is not to find a single "correct" temperature, but to understand that porcelain firing is a programmed cycle with distinct stages. The exact temperatures are dictated by the specific type of ceramic and the desired outcome, such as building up layers or applying a final glaze.

Why Firing is a Process, Not a Number

Asking for a single firing temperature is like asking for the single "baking temperature" for a multi-layered cake. Different layers and the final icing all require different conditions. Dental porcelain is the same.

The entire procedure is managed by a dental furnace, which runs a pre-set or custom program to control the temperature climb rate, hold times, and cooling.

The Critical Stages of a Firing Cycle

Each firing program consists of several key phases designed to transform the chalky porcelain powder into a dense, strong, and aesthetic restoration.

Stage 1: Drying Before high heat is applied, the furnace gently heats the restoration at a low temperature, typically around 500-600°C (932-1112°F). This crucial first step slowly evaporates all moisture from the porcelain paste, preventing steam from causing cracks or bubbles later.

Stage 2: Sintering (The High-Heat Firing) This is the main firing stage where the magic happens. The temperature is raised significantly to the material's specific maturation point, usually in that 800°C to 1300°C range. During sintering, the individual porcelain particles fuse together, shrinking and densifying to create a strong, solid mass.

Stage 3: Glazing The final step is often a separate, slightly lower temperature firing. The glaze firing melts a thin, glassy layer onto the surface of the restoration. This creates a smooth, high-shine, stain-resistant, and natural-looking finish.

Key Factors That Determine Firing Temperature

The exact program and peak temperatures are never arbitrary. They are dictated by precise technical and clinical requirements.

Material Composition

Different types of dental ceramics have vastly different compositions and, therefore, different melting and sintering points.

- High-fusing porcelains, often used for denture teeth, require higher temperatures.

- Low-fusing porcelains, used for veneers and crowns layered over a metal or zirconia core, fire at much lower temperatures to avoid damaging the underlying structure.

The Manufacturer's Specification

Every ceramic manufacturer provides an Instructions for Use (IFU) document. This is the definitive guide. It contains the exact, tested firing programs for their material, and deviating from it is a significant risk.

The Type of Firing

A technician fires a single restoration multiple times. A "body" or "dentin" bake will have a different temperature profile than a final "glaze" bake on the same piece. Each subsequent firing is typically done at a slightly lower temperature to avoid distorting the previous layers.

Understanding the Trade-offs and Pitfalls

Controlling the firing cycle is paramount for success. Small deviations can lead to complete failure of the restoration.

The Risk of Firing Too Hot or Too Fast

Heating the porcelain too quickly or to an excessive temperature can cause pyroplasticity, where the material begins to slump and lose its shape. It can also create a glassy, unnatural appearance and may compromise the color.

The Problem with Firing Too Cool or Too Slow

Under-firing is equally problematic. If the porcelain doesn't reach its optimal sintering temperature, the particles will not fuse completely. This results in a weak, porous, and opaque restoration that is prone to fracture and staining.

Making the Right Choice for Your Goal

Your approach to the firing program should be directly linked to the clinical or technical objective at hand.

- If your primary focus is achieving maximum strength for a core: You must adhere strictly to the manufacturer's sintering program to ensure full densification.

- If your primary focus is achieving ideal aesthetics on a veneer: Pay close attention to the specific programs for each layer (opaque, body, enamel, glaze) to build up translucency and color correctly.

- If your primary focus is procedural accuracy and efficiency: Always verify the correct program is selected in the furnace before every cycle, as a simple mistake can ruin the restoration.

Ultimately, the firing cycle is a precise thermal recipe that transforms raw materials into a durable and lifelike dental restoration.

Summary Table:

| Stage | Purpose | Typical Temperature Range |

|---|---|---|

| Drying | Removes moisture to prevent cracks | 500°C - 600°C (932°F - 1112°F) |

| Sintering | Fuses particles for strength | 800°C - 1300°C (1472°F - 2372°F) |

| Glazing | Creates a smooth, glossy finish | Lower than sintering temperature |

Achieve Perfect Results with Every Firing Cycle

Mastering the precise thermal recipe for porcelain is critical for creating strong, aesthetic, and long-lasting dental restorations. The right dental furnace and consumables are essential for consistent success.

KINTEK specializes in high-precision lab equipment and consumables for dental laboratories. We provide the reliable tools you need to execute perfect firing cycles, ensuring maximum strength for cores and ideal aesthetics for veneers.

Contact us today to discuss how our solutions can enhance your lab's efficiency and restoration quality.

#ContactForm to get started!

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Spark Plasma Sintering Furnace SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the main difference between soldering and brazing? Choose the Right Metal Joining Method

- What is the advantage of firing porcelain in a vacuum? Achieve Denser, Stronger, and More Aesthetic Dental Restorations

- Why are porcelain fired under vacuum? To Eliminate Porosity for Superior Strength & Translucency

- What is the function of a porcelain furnace? Precision Firing for Lifelike Dental Restorations

- What is the difference between VAR and VIM? Legacy Vimscript Variables vs. Modern Neovim API