The primary types of laboratory freeze dryers are Manifold, Shelf (or Tray), and Bench-Top models. Each is designed to remove moisture from sensitive materials through sublimation, preserving their physical structure and biological integrity. Their applications span critical work in pharmaceuticals, biological research, and food science, where maintaining the original properties of a substance is paramount.

Your choice between a manifold, shelf, or bench-top freeze dryer is driven by your specific application's need for sample volume, format, and process control. Understanding these differences is key to ensuring sample integrity and process efficiency.

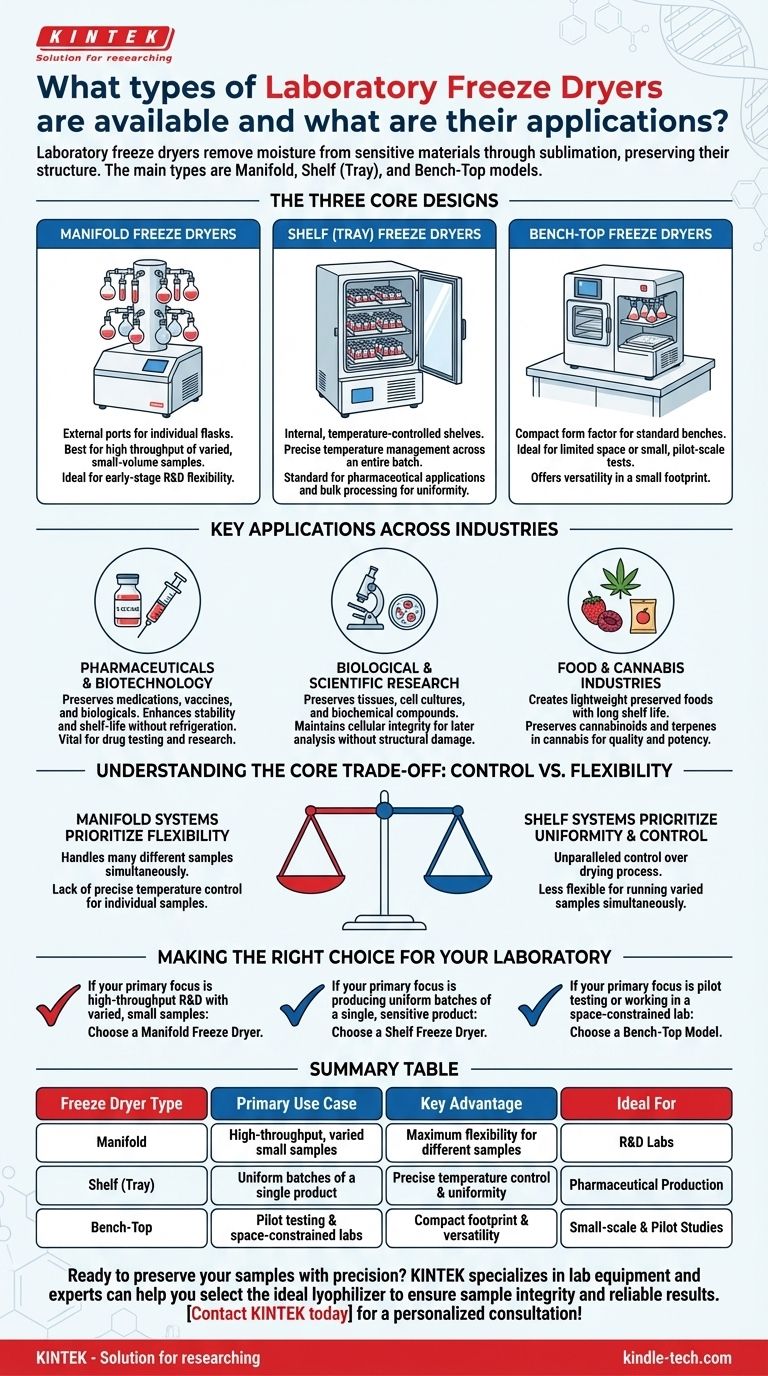

The Three Core Designs of Laboratory Freeze Dryers

The fundamental technology of freeze drying (lyophilization) is consistent, but the equipment's design varies significantly to accommodate different laboratory needs. The main distinction lies in how the samples are held and processed.

Manifold Freeze Dryers

A manifold freeze dryer is characterized by external ports where individual flasks or vials are attached. This design allows for processing multiple, often different, samples simultaneously.

It is best suited for laboratories handling a high throughput of varied, small-volume samples. Researchers in early-stage R&D often favor this design for its flexibility.

Shelf (Tray) Freeze Dryers

Shelf freeze dryers contain internal, temperature-controlled shelves where samples are placed in trays or vials. This allows for precise and uniform temperature management across an entire batch.

This model is the standard in pharmaceutical applications and bulk processing, where consistency and control are critical for producing a uniform final product.

Bench-Top Freeze Dryers

This category refers more to the unit's form factor than its processing method. A bench-top freeze dryer is a compact unit designed to fit on a standard laboratory bench.

These systems are ideal for labs with limited space or for conducting smaller, pilot-scale tests. They can incorporate either a manifold or a small shelf system, offering versatility in a smaller footprint.

Key Applications Across Industries

The ability to remove water without heat makes freeze drying indispensable for preserving delicate, heat-sensitive, or unstable materials across many scientific and commercial fields.

Pharmaceuticals and Biotechnology

In pharmaceuticals, freeze drying is essential for preserving medications, vaccines, and other biologicals. This process enhances the stability and shelf-life of drugs, making them easier to store and transport without refrigeration.

It is also a cornerstone of drug testing and research, enabling the long-term preservation of biological samples for analysis.

Biological and Scientific Research

Biologists and researchers use freeze dryers to preserve tissues, cell cultures, and biochemical compounds. The process maintains the integrity of delicate cellular structures for later examination.

This ensures that samples can be studied without the structural damage that could be caused by other drying methods.

Food and Cannabis Industries

Food scientists use freeze drying to create lightweight, preserved foods with an exceptionally long shelf life that retain much of their original flavor and nutritional value.

Similarly, the cannabis industry uses freeze drying to preserve cannabinoids and terpenes. This enhances the quality, potency, and shelf-life of the final product by protecting these sensitive compounds.

Understanding the Core Trade-off: Control vs. Flexibility

Choosing the right freeze dryer involves balancing the need for precise process control against the need for sample flexibility and throughput.

Manifold Systems Prioritize Flexibility

The primary advantage of a manifold system is its ability to handle many different samples at the same time. You can add or remove flasks independently.

The trade-off is a lack of precise temperature control for each individual sample, as they are all subjected to the same vacuum and condenser temperature.

Shelf Systems Prioritize Uniformity and Control

A shelf system offers unparalleled control over the drying process. The ability to manage shelf temperature is critical for optimizing the process for a specific product.

This design is less flexible for running varied samples simultaneously and is geared toward producing consistent, uniform batches.

Making the Right Choice for Your Laboratory

Your decision should be based directly on your sample type, volume, and required level of process control.

- If your primary focus is high-throughput R&D with varied, small samples: A manifold freeze dryer offers the flexibility to process many different materials at once.

- If your primary focus is producing uniform batches of a single, sensitive product: A shelf freeze dryer provides the critical temperature control needed for consistency, which is vital in pharmaceutical applications.

- If your primary focus is pilot testing or working in a space-constrained lab: A bench-top model offers a compact footprint with the versatility for smaller-scale projects.

Selecting the right freeze dryer design is fundamental to preserving the integrity of your materials and achieving reliable, repeatable results.

Summary Table:

| Freeze Dryer Type | Primary Use Case | Key Advantage | Ideal For |

|---|---|---|---|

| Manifold | High-throughput, varied small samples | Maximum flexibility for different samples | R&D Labs |

| Shelf (Tray) | Uniform batches of a single product | Precise temperature control & uniformity | Pharmaceutical Production |

| Bench-Top | Pilot testing & space-constrained labs | Compact footprint & versatility | Small-scale & Pilot Studies |

Ready to preserve your samples with precision? Choosing the correct freeze dryer is critical for your lab's success. KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the ideal manifold, shelf, or bench-top lyophilizer to ensure sample integrity, process efficiency, and reliable results for your work in pharmaceuticals, biotech, or food science. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What are the advantages of using a Laboratory Freeze Dryer? Preserve Sample Integrity with Lyophilization

- In which fields is the laboratory freeze dryer commonly used? Essential for Biopharma, Food Science & Research

- What is freeze drying and how does it work? A Complete Guide to Lyophilization

- What is a Laboratory Freeze Dryer and what is its primary function? Achieve Perfect Preservation of Sensitive Materials

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure