At its core, the laboratory freeze dryer is a critical instrument in any field where preserving the integrity of a sensitive substance after removing water is paramount. It is most commonly used in the biopharmaceutical, biotechnology, food science, and scientific research sectors. These industries rely on freeze-drying to stabilize materials that would otherwise be damaged by heat-based drying methods.

A laboratory freeze dryer's value is not just in removing water, but in how it removes it. By freezing a material and then turning the ice directly into vapor under a vacuum (sublimation), it preserves the delicate structure and chemical integrity of the original substance.

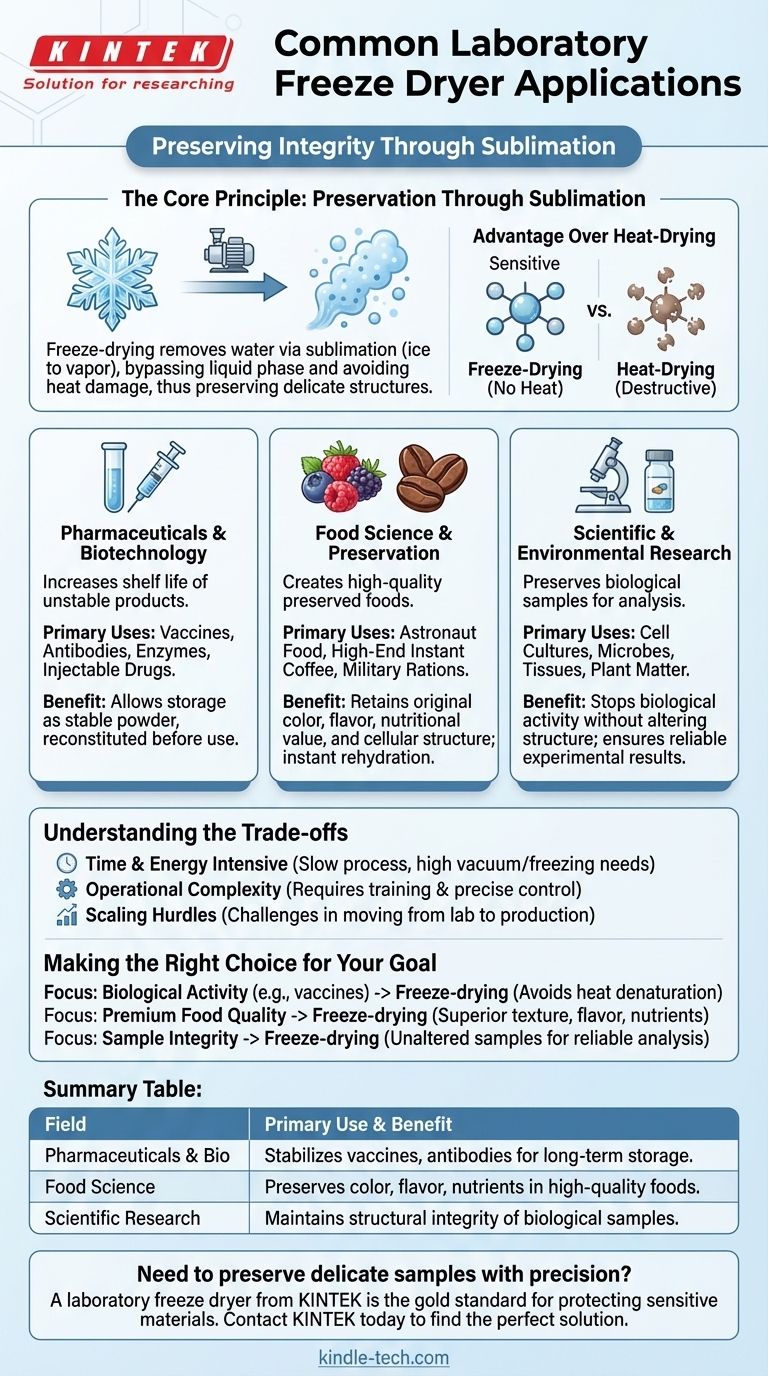

The Core Principle: Preservation Through Sublimation

Before examining its uses, it is essential to understand why freeze-drying is so effective. The entire process is built to avoid the destructive force of heat.

How Freeze-Drying Works

A laboratory freeze dryer first freezes the water-containing material into a solid. Next, it creates a powerful vacuum, and under these low-pressure conditions, the frozen water sublimates—meaning it transitions directly from solid ice into a gas. This vapor is then collected on a cold condenser, leaving behind a perfectly dry, structurally intact product.

The Advantage Over Heat-Drying

Conventional drying uses heat to evaporate water. While effective, this heat can destroy or denature sensitive biological and chemical structures, such as proteins, microbes, and complex flavor compounds. Freeze-drying completely avoids this, ensuring the final product remains as close to its original state as possible.

Key Applications by Industry

The ability to remove water without heat damage makes the freeze dryer indispensable across several high-tech fields.

Pharmaceuticals and Biotechnology

This is arguably the most critical application. Freeze-drying, or lyophilization, is used to increase the shelf life of products like vaccines, antibodies, enzymes, and other injectable drugs. Many of these molecules are unstable in a liquid solution and would be destroyed by heat. Freeze-drying allows them to be stored and transported as a stable powder, ready to be reconstituted with a sterile liquid just before use.

Food Science and Preservation

In the food industry, freeze-drying is used to create high-quality preserved foods that retain their original color, flavor, and nutritional value. Unlike simple dehydration, which can make food tough and shrunken, freeze-drying maintains the food's cellular structure. This results in a lightweight, porous product that rehydrates instantly, such as in astronaut food, high-end instant coffee, and military rations.

Scientific and Environmental Research

For researchers, sample integrity is non-negotiable. Freeze-drying is used to preserve biological samples like cell cultures, microbes, tissues, or plant matter for long-term storage and analysis. By stopping all biological activity without altering the sample's structure, scientists can ensure that their experimental results are reliable and that they are studying the sample in its original state, not one degraded by time or a poor preservation method.

Understanding the Trade-offs

While powerful, freeze-drying is not a universal solution. It involves specific challenges that make it suitable for high-value applications.

The Cost of Precision: Time and Energy

The freeze-drying process is notably slow, often taking 24 hours or more for a single batch. The deep-freezing and high-vacuum systems are also very energy-intensive compared to simpler drying methods.

Operational Complexity

Laboratory freeze dryers are sophisticated instruments that require user training. Achieving the correct balance of temperature and pressure is crucial for a successful outcome, and improper use can lead to sample loss or incomplete drying. Scaling the process from a lab bench to industrial production presents significant engineering hurdles.

Making the Right Choice for Your Goal

Deciding whether to use a freeze dryer depends entirely on the nature of your material and your ultimate objective.

- If your primary focus is preserving biological activity (e.g., vaccines, enzymes): Freeze-drying is the gold standard because it avoids the heat that would denature these delicate structures.

- If your primary focus is premium food quality and stability: Freeze-drying offers superior preservation of texture, flavor, and nutrients compared to conventional dehydration.

- If your primary focus is sample integrity for research: Freeze-drying ensures your samples remain unaltered, providing a reliable and stable baseline for future analysis.

Ultimately, the laboratory freeze dryer is a cornerstone technology for any field that requires the highest standard of material preservation.

Summary Table:

| Field | Primary Use & Benefit |

|---|---|

| Pharmaceuticals & Biotechnology | Stabilizes vaccines, antibodies, and injectable drugs for long-term storage. |

| Food Science | Preserves color, flavor, and nutritional value in high-quality preserved foods. |

| Scientific Research | Maintains structural integrity of biological samples for reliable analysis. |

Need to preserve delicate samples with precision?

A laboratory freeze dryer from KINTEK is the gold standard for protecting the integrity of sensitive materials in biopharmaceuticals, food science, and research. By using sublimation to remove water without heat damage, our equipment ensures your vaccines, enzymes, and biological samples remain stable and effective.

Contact KINTEK today to find the perfect freeze-drying solution for your laboratory's specific needs and enhance your preservation capabilities.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What happens during the freezing phase of lyophilization? Master the Critical First Step for Product Integrity

- What is the basic process of freeze drying? A Guide to Lyophilization Stages and Benefits

- What occurs during the secondary drying phase? Master the Final Step for Product Stability

- What physical property enhancements does freeze drying provide for pharmaceutical products? Achieve Superior Stability & Global Distribution

- What are the three main stages of the freeze-drying process? Master Sublimation and Desorption