At its core, a laboratory freeze dryer, also known as a lyophilizer, is a specialized piece of equipment designed to preserve perishable materials by removing water. It accomplishes this not through heat, but by first freezing the material and then using a high-vacuum environment to cause the frozen water to transform directly from a solid (ice) into a gas (vapor), a process called sublimation.

The fundamental value of a freeze dryer isn't simply removing water; it's preserving the delicate structural and biological integrity of a substance. By bypassing the liquid phase, it protects heat-sensitive materials that would be destroyed by conventional drying methods.

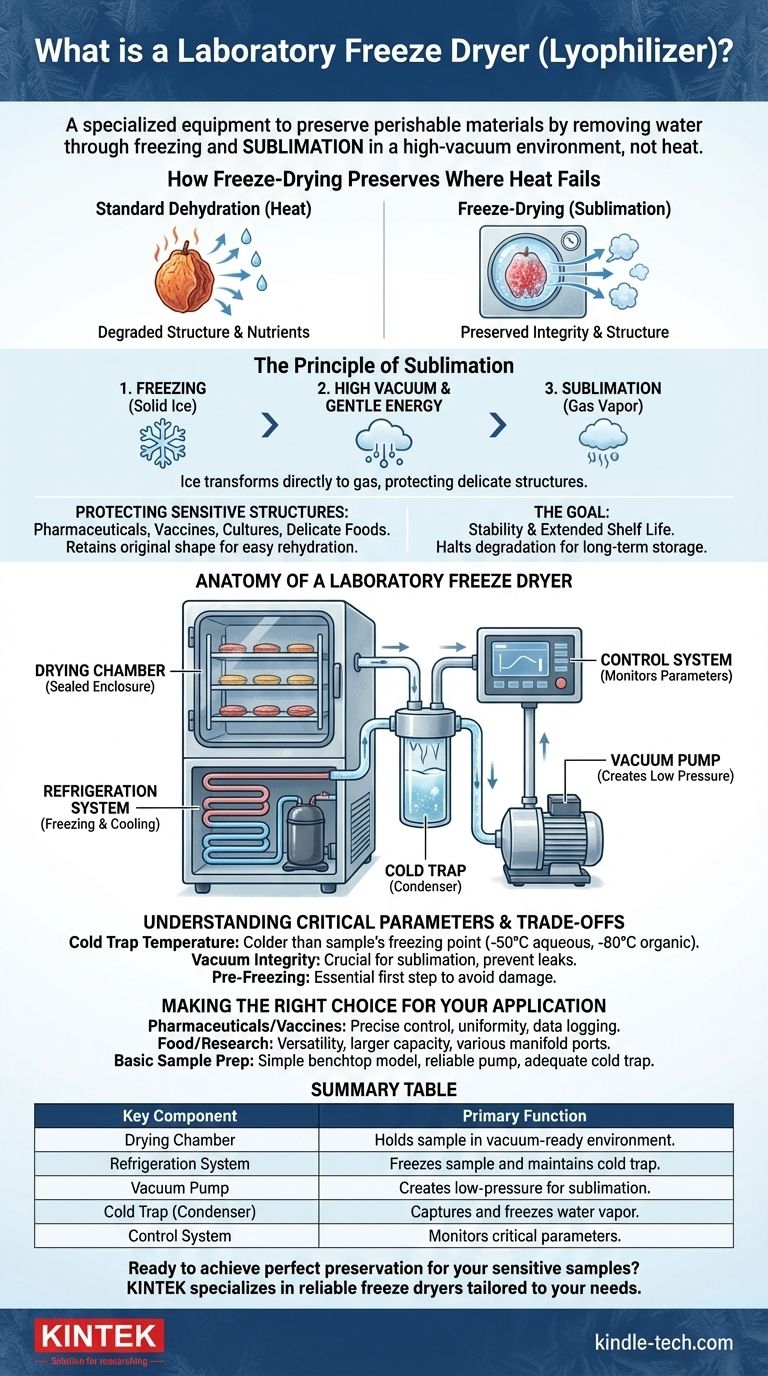

How Freeze-Drying Preserves Where Heat Fails

Standard dehydration uses heat to evaporate water, which can degrade the chemical structure, nutritional value, and biological activity of sensitive samples. Freeze-drying is a far gentler alternative.

The Principle of Sublimation

The entire process hinges on sublimation. Under normal atmospheric pressure, ice melts into water before evaporating.

A freeze dryer creates a deep vacuum, drastically lowering the pressure. In this environment, applying a small amount of energy is enough to make the ice molecules transition directly into a gaseous state, leaving the original material's structure intact.

Protecting Sensitive Structures

This method is critical for preserving materials like pharmaceuticals, vaccines, microbial cultures, and delicate food products.

Because the water is removed as a solid, the original shape and framework of the material are not compromised. This results in a porous, lightweight substance that can be easily rehydrated.

The Goal: Stability and Extended Shelf Life

By removing nearly all water content, freeze-drying effectively halts most biological and chemical reactions that cause degradation.

This makes the material stable for long-term storage at ambient temperatures, significantly extending its shelf life and simplifying transportation.

Anatomy of a Laboratory Freeze Dryer

A freeze dryer is a sophisticated system with several interconnected components working in concert. While designs vary, they all share a core set of parts.

The Drying Chamber

This is the sealed enclosure where the material is placed for processing. It's built to withstand a deep vacuum and varying temperatures.

The Refrigeration System

This powerful system, often involving a compressor and evaporator coils, is responsible for freezing the material before the drying process begins and keeping the cold trap at extremely low temperatures.

The Vacuum Pump

The vacuum pump is the heart of the pressure reduction system. It removes air and other gases from the drying chamber to create the low-pressure environment necessary for sublimation to occur.

The Cold Trap (Condenser)

Positioned between the drying chamber and the vacuum pump, the cold trap is a surface chilled to a very low temperature (e.g., -50°C to -80°C).

Its sole purpose is to attract and capture the water vapor leaving the sample, freezing it back into solid ice. This protects the vacuum pump from moisture, which could damage it.

The Control System

Modern freeze dryers use an electrical control system to manage and monitor the critical parameters of the process, including temperature, pressure (vacuum level), and time.

Understanding the Trade-offs and Critical Parameters

Choosing or operating a freeze dryer effectively requires understanding the key variables that influence its performance. An error in one of these can compromise the entire process.

Cold Trap Temperature is Not One-Size-Fits-All

The temperature of the cold trap must be significantly colder than the freezing point of your sample's solvent. For aqueous solutions, a -50°C trap is often sufficient, but for samples with organic solvents, a -80°C or colder trap may be necessary to capture the vapors effectively.

The Importance of Vacuum Integrity

The entire process depends on achieving and maintaining a deep vacuum. Leaks in seals, hoses, or the chamber itself will prevent sublimation and can ruin the batch. Regular inspection and maintenance are crucial.

Pre-Freezing is a Critical First Step

Properly freezing the material before applying the vacuum is non-negotiable. If the material is not fully frozen, it can melt and boil under vacuum, destroying the sample's structure.

Making the Right Choice for Your Application

The ideal freeze dryer is directly tied to the materials you are working with and your ultimate goal.

- If your primary focus is preserving pharmaceuticals or vaccines: Prioritize models with precise shelf temperature control, excellent temperature uniformity, and robust data logging for process validation.

- If your primary focus is food preservation or diverse research samples: Look for a versatile unit with a larger capacity, multiple manifold ports for flasks, and a sufficiently low cold trap temperature for various solvents.

- If your primary focus is basic sample preparation for analysis: A simpler benchtop model with a reliable vacuum pump and an adequate cold trap temperature will likely meet your needs without unnecessary complexity.

Ultimately, understanding the principles of lyophilization empowers you to select and operate this equipment to achieve perfect preservation.

Summary Table:

| Key Component | Primary Function |

|---|---|

| Drying Chamber | Holds the sample in a sealed, vacuum-ready environment. |

| Refrigeration System | Freezes the sample and maintains the cold trap temperature. |

| Vacuum Pump | Creates the low-pressure environment necessary for sublimation. |

| Cold Trap (Condenser) | Captures and freezes water vapor, protecting the vacuum pump. |

| Control System | Monitors and manages critical parameters like temperature and pressure. |

Ready to achieve perfect preservation for your sensitive samples? The right freeze dryer is critical for success in pharmaceuticals, food science, and research. KINTEK specializes in providing reliable lab equipment, including freeze dryers tailored to your specific application. Our experts can help you select the ideal model to ensure stability, extend shelf life, and protect your valuable materials. Contact our team today to find your perfect laboratory solution!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the function of a freeze dryer in the ice-templating process? Preserving Aligned Pore Scaffolds for LAGP

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability