The primary advantage of a laboratory freeze dryer is its ability to preserve the most delicate, heat-sensitive materials by removing water without damaging their fundamental structure. This process, known as lyophilization, maintains the biological and chemical integrity of samples like pharmaceuticals, proteins, and microorganisms, enabling long-term storage and perfect rehydration.

A freeze dryer's true value isn't just in dehydration; it's in its unique ability to bypass the destructive liquid water phase entirely. This preserves a sample's original structure and activity, a feat that simple heating or evaporation cannot achieve.

How Freeze-Drying Achieves Superior Preservation

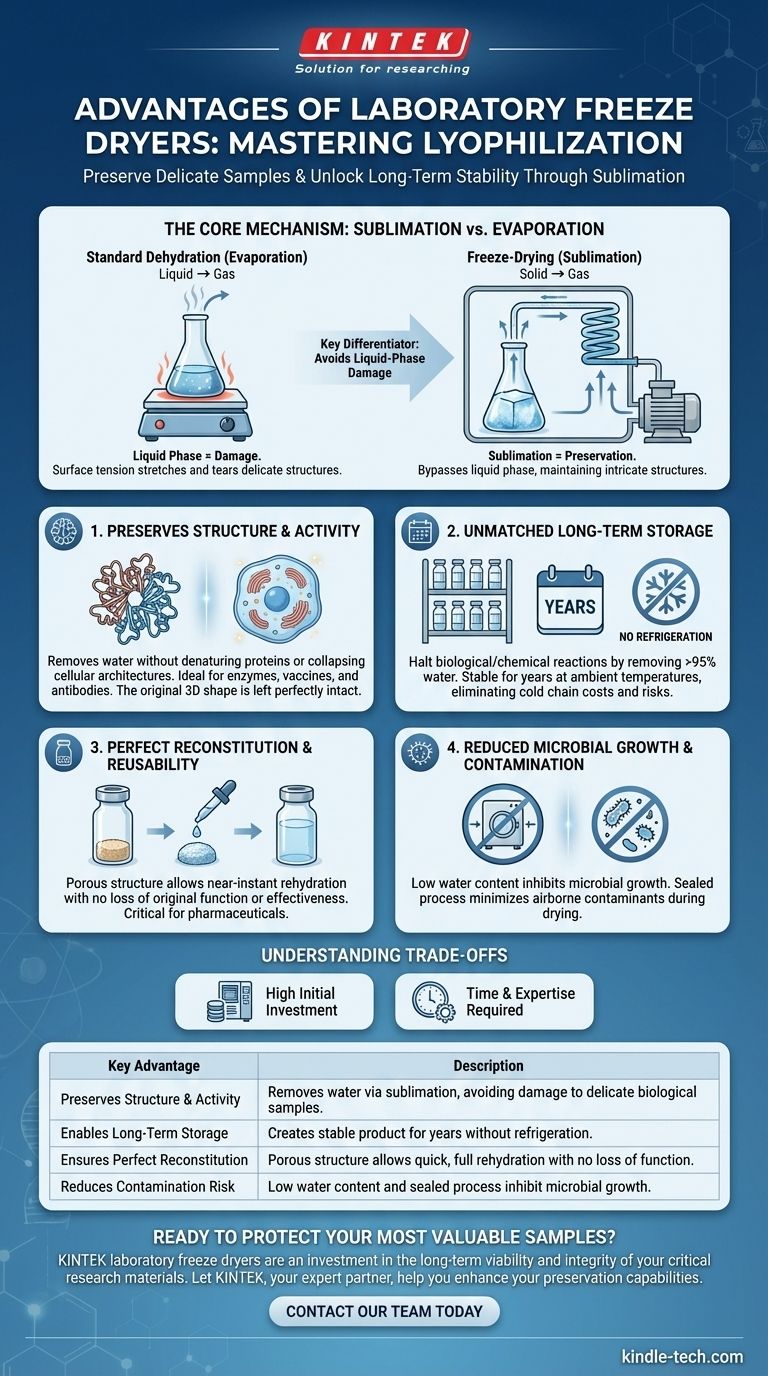

To understand the advantages of a freeze dryer, you must first understand its core mechanism: sublimation. This is the key differentiator from all other drying methods.

The Principle of Sublimation

A freeze dryer first freezes a sample solid. Then, by creating a deep vacuum, it allows the frozen water crystals to turn directly into a gas (water vapor) without ever melting into a liquid.

This vapor is then collected on a freezing-cold condenser coil inside the unit, permanently removing it from the sample.

Avoiding Liquid-Phase Damage

Standard dehydration (evaporation) forces water molecules to pass through and out of a sample's structure as a liquid. This process creates immense surface tension that can stretch, tear, and collapse delicate cellular or molecular architectures.

Freeze-drying completely avoids this. By keeping the water solid until it becomes a gas, the sample's intricate framework—from a cell wall to a complex protein—is left behind intact and undamaged.

Preserving Biological and Chemical Activity

For materials like enzymes, vaccines, or antibodies, their function is tied directly to their three-dimensional shape. The gentle nature of sublimation ensures these complex structures are not denatured or altered.

The final lyophilized product is a porous, structurally identical "scaffold" of the original material, ready to be reactivated simply by adding water.

The Tangible Benefits in the Lab

The underlying principle of sublimation translates into several powerful, practical advantages for researchers and technicians.

Unmatched Stability for Long-Term Storage

By removing over 95% of the water, freeze-drying effectively halts most biological and chemical reactions, including those that cause degradation.

This creates a product that is exceptionally stable for years, often without the need for constant, energy-intensive refrigeration. This eliminates the cost and risk associated with maintaining a cold chain.

Perfect Reconstitution and Reusability

Because the sample's original porous structure is preserved, water can re-enter it almost instantly and completely. This is known as reconstitution.

A freeze-dried vial of protein, for example, can be brought back to its original state in seconds with no loss of effectiveness, which is critical for pharmaceuticals and laboratory reagents.

Reduced Microbial Growth and Contamination

Water is essential for the growth of bacteria and fungi. By removing it so thoroughly, freeze-drying makes the material an inhospitable environment for microbial contaminants.

Furthermore, because the process occurs within a sealed chamber, the risk of introducing airborne contaminants during drying is minimized.

Understanding the Trade-offs and Limitations

While powerful, a freeze dryer is a specialized piece of equipment with specific trade-offs that must be considered.

The Investment: High Initial Cost

Laboratory freeze dryers are complex machines with refrigeration, vacuum, and control systems. This results in a significant upfront capital investment compared to simpler dehydration equipment like ovens or desiccators.

The Process: Time and Expertise Required

Lyophilization is not a fast process. A typical cycle can last anywhere from 12 hours to several days, depending on the sample type and volume.

Operating the equipment also requires a degree of training to develop proper protocols, perform routine maintenance on vacuum pumps and seals, and troubleshoot cycles.

Sample Compatibility: Not a Universal Solution

Freeze-drying is less effective for samples with high concentrations of non-volatile solvents, fats, or sugars. These substances can interfere with the sublimation process or result in a sticky, collapsed final product instead of a dry, porous cake.

Making the Right Choice for Your Preservation Needs

Deciding whether to use a freeze dryer depends entirely on the nature of your sample and your ultimate goal.

- If your primary focus is preserving biological activity (e.g., enzymes, vaccines, proteins): Freeze-drying is the gold standard, as it is unmatched in its ability to maintain molecular structure and function.

- If your primary focus is long-term archival of samples at ambient temperature: Lyophilization provides exceptional stability, eliminating the need for cold chain logistics and freezer space.

- If your primary focus is simple water removal from robust, non-sensitive materials: A more cost-effective method like oven drying or vacuum desiccation may be a more efficient choice.

Ultimately, a freeze dryer is an investment in the long-term integrity and future viability of your most critical and delicate samples.

Summary Table:

| Key Advantage | Description |

|---|---|

| Preserves Structure & Activity | Removes water via sublimation, avoiding damage to delicate biological samples like proteins and cells. |

| Enables Long-Term Storage | Creates a stable, dry product that can be stored for years without refrigeration. |

| Ensures Perfect Reconstitution | Porous structure allows samples to be quickly and fully rehydrated with no loss of function. |

| Reduces Contamination Risk | Low water content and sealed process inhibit microbial growth and minimize contamination. |

Ready to protect your most valuable samples?

A laboratory freeze dryer from KINTEK is an investment in the long-term viability and integrity of your critical research materials. Our lyophilization equipment is designed to deliver the precise, gentle drying required for pharmaceuticals, proteins, and other sensitive biologicals.

Let KINTEK, your expert partner in lab equipment, help you enhance your preservation capabilities. Contact our team today to discuss your specific application and find the ideal freeze-drying solution for your laboratory.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability

- What is the function of Freeze-thaw Equipment in Au-(PNiPAAm/PVA) hydrogel? Achieve High-Speed Photothermal Actuation

- What is the function of a freeze dryer in the ice-templating process? Preserving Aligned Pore Scaffolds for LAGP

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis