In essence, freeze-drying is a method of preserving materials by removing water without using damaging heat. This process, also known as lyophilization, works by first freezing the material solid. Then, under a strong vacuum, the frozen water is converted directly from a solid (ice) into a gas (vapor) without ever melting into a liquid. This gentle technique perfectly preserves the item's original structure, nutritional value, and biological activity.

The core problem with traditional drying is that heat and the physical movement of liquid water destroy delicate structures. Freeze-drying solves this by bypassing the liquid phase entirely, allowing for a level of preservation that is impossible with any other method.

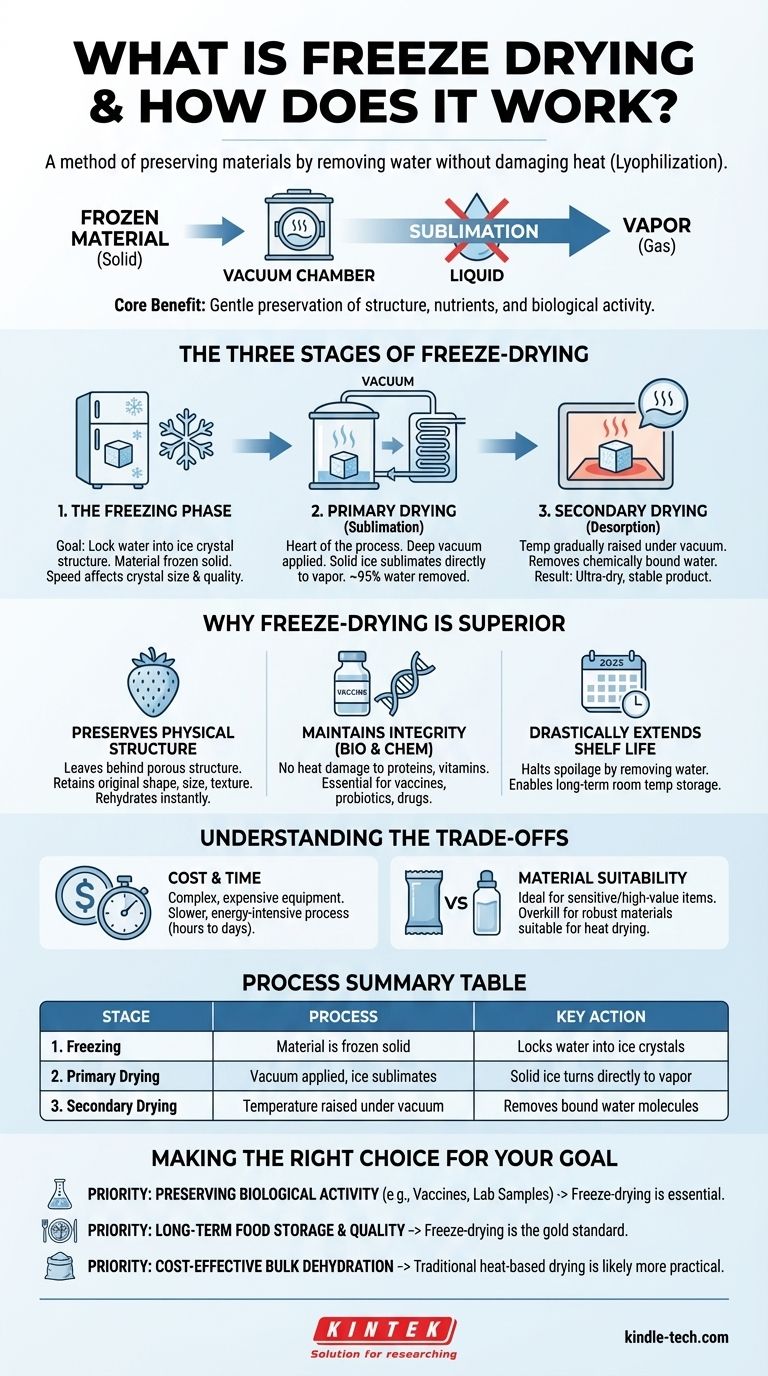

The Three Stages of Freeze-Drying

The process is a carefully controlled, three-part cycle designed to gently remove water while keeping the product's core characteristics intact. Each stage serves a distinct purpose.

Stage 1: The Freezing Phase

The first step is to lower the product's temperature until it is completely frozen solid. The goal is to lock all water into an ice crystal structure.

How a product is frozen—quickly or slowly—can influence the size of the ice crystals, which in turn affects the speed of the next stage and the quality of the final product.

Stage 2: Primary Drying (Sublimation)

This is the heart of the freeze-drying process. A deep vacuum is applied to the frozen product inside the chamber.

This combination of low pressure and low temperature forces the ice to undergo sublimation—transforming directly from a solid into a vapor. This water vapor is then drawn out of the chamber and collected on an extremely cold condenser coil, turning back into ice. About 95% of the water is removed during this stage.

Stage 3: Secondary Drying (Desorption)

Even after sublimation, a small amount of water remains chemically bound to the material. To remove this, the temperature is gradually and carefully raised while the product remains under vacuum.

This final step breaks the bonds between the remaining water molecules and the product, drawing out the last traces of moisture. The result is an exceptionally dry and stable product.

Why Freeze-Drying is a Superior Preservation Method

The benefits of freeze-drying stem directly from its ability to remove water without the damaging effects of heat or liquid-phase evaporation.

Preserving Physical Structure

Because the water turns to vapor from a solid state, it leaves behind a porous, unchanged structure. This is why freeze-dried foods, like astronaut ice cream or emergency rations, retain their original shape, size, and texture, rehydrating almost instantly.

Maintaining Biological and Chemical Integrity

Heat denatures proteins, destroys vitamins, and renders sensitive pharmaceuticals like vaccines ineffective. By operating at low temperatures, freeze-drying keeps these delicate molecules intact.

This makes it an essential process for stabilizing biological samples, producing live-culture probiotics, and manufacturing life-saving drugs.

Drastically Extending Shelf Life

The primary driver of spoilage is water, which enables the growth of bacteria, mold, and other microorganisms. By removing virtually all water, freeze-drying halts these biological processes.

This allows perishable materials to be stored safely at room temperature for years, or even decades, without degrading.

Understanding the Trade-offs

Despite its clear advantages, freeze-drying is not a universal solution. It involves specific equipment and operational costs that make it a deliberate choice.

Cost and Time

Freeze-drying equipment is complex and expensive. The process is also significantly slower and more energy-intensive than conventional heat-based dehydration. A cycle can take anywhere from several hours to multiple days to complete.

Material Suitability

While ideal for sensitive and high-value products, freeze-drying can be overkill for robust materials that can withstand simple air or heat drying. The decision to use it depends entirely on whether the product's integrity would be compromised by a cheaper, faster method.

Making the Right Choice for Your Goal

Selecting the correct dehydration method requires you to first define your priority.

- If your primary focus is preserving biological activity (e.g., vaccines, lab samples): Freeze-drying is often the only viable method to maintain molecular integrity and effectiveness.

- If your primary focus is long-term food storage with maximum quality retention: Freeze-drying is the gold standard for preserving taste, texture, and nutritional value far beyond other methods.

- If your primary focus is cost-effective bulk dehydration of robust materials: Traditional heat-based drying is likely a more practical and economical choice.

Understanding this principle of sublimation empowers you to select the right preservation tool for any sensitive material.

Summary Table:

| Stage | Process | Key Action | Result |

|---|---|---|---|

| 1. Freezing | Material is frozen solid | Locks water into ice crystals | Creates stable structure for drying |

| 2. Primary Drying | Vacuum applied, ice sublimates | Solid ice turns directly to vapor | Removes ~95% of water |

| 3. Secondary Drying | Temperature raised under vacuum | Removes bound water molecules | Achieves ultra-dry, stable product |

Ready to preserve your sensitive materials with precision? KINTEK specializes in laboratory equipment and consumables, offering reliable freeze-drying solutions for pharmaceuticals, food science, and research applications. Our expertise ensures your delicate samples, vaccines, and high-value products maintain their integrity through optimal lyophilization processes. Contact us today to discuss how our freeze-drying systems can enhance your preservation outcomes and extend shelf life while protecting biological activity.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the function of a freeze dryer in the ice-templating process? Preserving Aligned Pore Scaffolds for LAGP

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- What is the purpose of an evaporator? The Key Component That Creates Cooling

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability