In short, compression moulding is used to produce strong, durable parts, particularly from high-strength thermoset plastics and composites. It is a go-to process in the automotive, aerospace, electrical, and heavy industrial sectors for creating large, relatively simple components like vehicle body panels, electrical enclosures, and structural elements where material performance is more critical than complex design features or high-speed production.

The core decision to use compression moulding comes down to a trade-off: you gain exceptional strength and the ability to use advanced composite materials, but you sacrifice the high-speed cycle times and intricate design complexity offered by processes like injection moulding.

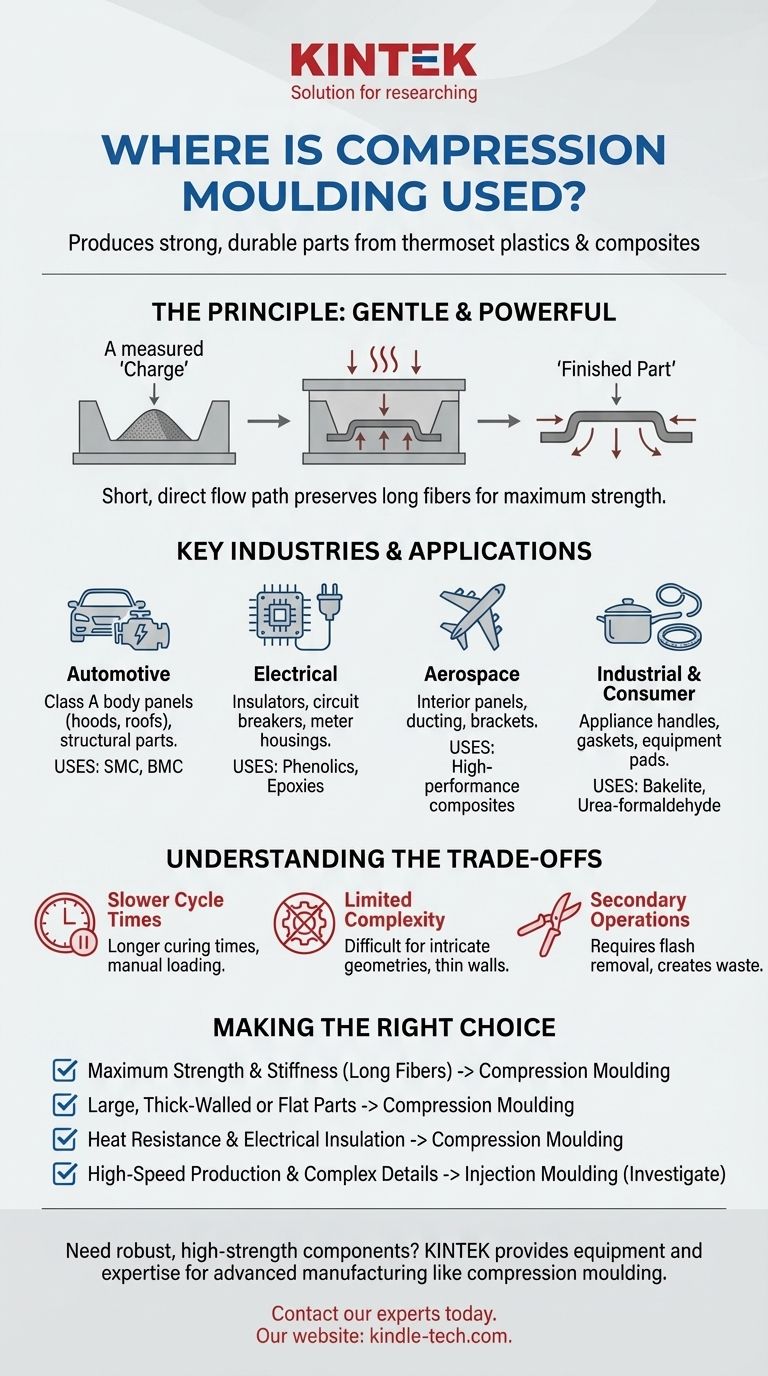

The Principle: Why Compression Moulding Excels

To understand where compression moulding is used, you must first understand its fundamental advantage. The process is simple, direct, and powerful.

The Process at a Glance

A pre-measured amount of material, called a "charge," is placed directly into a heated, open mould cavity. The mould is then closed, and immense pressure is applied, forcing the material to flow and fill every part of the cavity. The combination of heat and pressure initiates a chemical reaction (curing) that permanently hardens the part.

The Impact of Gentle Material Flow

Unlike injection moulding, where molten plastic is forced through narrow channels (gates and runners), compression moulding involves a much shorter, gentler flow path. This is the key to its primary benefit.

This gentle process preserves the integrity of long glass or carbon fibers within composite materials, which is crucial for achieving maximum strength. The fibers remain properly distributed and undamaged, resulting in a finished part with superior mechanical properties.

Key Industries and Applications

The unique benefits of compression moulding make it the preferred choice in specific, demanding applications where other processes fall short.

Automotive and Heavy Transport

This is the largest market for compression moulding. It's used for Class A exterior body panels (hoods, roofs, decklids), under-hood components, and interior structural parts.

The primary driver is the use of Sheet Moulding Compound (SMC) and Bulk Moulding Compound (BMC). These are composite materials that offer a high strength-to-weight ratio, corrosion resistance, and the ability to produce very large, dimensionally stable parts.

Electrical and Electronics

Thermoset materials like phenolics and epoxies have excellent dielectric properties (they don't conduct electricity) and high heat resistance.

Compression moulding is therefore ideal for making electrical insulators, circuit breakers, switchgear, and meter housings. The process creates dense, void-free parts that are critical for safety and long-term reliability in high-voltage applications.

Aerospace and Defense

In aerospace, every gram matters. High-performance composites are essential for creating lightweight yet incredibly strong components.

The process is used for interior panels, ducting, and non-critical structural brackets. The low internal stress of compression-moulded parts ensures dimensional stability under varying temperatures and pressures, a vital characteristic for aviation.

Industrial and Consumer Goods

Compression moulding is also used for a range of durable goods. It is perfect for producing cookware handles (using heat-resistant Bakelite), appliance housings, and even toilet seats (using urea-formaldehyde).

In industrial settings, its ability to handle tough materials makes it ideal for manufacturing gaskets, seals, and large composite equipment pads or covers.

Understanding the Trade-offs

No manufacturing process is perfect for every situation. Being objective means acknowledging the limitations of compression moulding.

Slower Cycle Times

The process often involves manual loading of the material charge and longer curing times (minutes, not seconds). This makes it slower and less suitable for extremely high-volume production compared to injection moulding.

Limited Part Complexity

Because the material doesn't flow through intricate channels, the process is not well-suited for parts with complex geometries, thin walls, or fine details. Undercuts and sharp internal features are difficult or impossible to produce without complex, costly tooling.

Secondary Operations and Waste

The process creates "flash"—excess material that is squeezed out between the two halves of the mould. This flash must be removed in a secondary trimming operation, which adds labor time and creates material waste.

Making the Right Choice for Your Goal

Selecting a manufacturing process depends entirely on your project's specific priorities.

- If your primary focus is maximum strength and stiffness using long-fiber composites: Compression moulding is the superior choice, as it protects fiber integrity better than any other high-volume process.

- If your primary focus is producing large, thick-walled, or relatively flat parts: This process is highly effective and often more cost-efficient for tooling than massive injection moulds.

- If your primary focus is heat resistance and electrical insulation: Compression moulding is the industry standard for creating robust thermoset components for the electrical sector.

- If your primary focus is high-speed production of complex, detailed parts: You should investigate injection moulding, as it is designed specifically for speed and geometric complexity.

Ultimately, compression moulding is the definitive choice when the inherent properties of the material are the most critical factor in your design's success.

Summary Table:

| Industry | Common Applications | Key Materials Used |

|---|---|---|

| Automotive | Body panels, under-hood components, structural parts | SMC, BMC (Sheet/Bulk Moulding Compound) |

| Aerospace & Defense | Interior panels, ducting, structural brackets | High-performance composites |

| Electrical & Electronics | Insulators, circuit breakers, switchgear | Phenolics, Epoxies |

| Industrial & Consumer Goods | Appliance housings, cookware handles, gaskets | Bakelite, Urea-formaldehyde |

Need robust, high-strength components for your lab or production line? KINTEK specializes in providing the equipment and expertise for advanced manufacturing processes like compression moulding. Whether you're developing new composite materials or require durable lab equipment consumables, our solutions are designed to meet the demanding needs of laboratories and industrial clients. Contact our experts today to discuss how we can support your project with reliable, high-performance solutions.

Visual Guide

Related Products

- Double Plate Heating Press Mold for Lab

- Warm Isostatic Press for Solid State Battery Research

- Automatic Laboratory Heat Press Machine

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

People Also Ask

- What are the different types of press machines? Choose the Right Heating Tech for Your Application

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- Why is it necessary to use high-precision temperature-controlled heating furnaces? Secure Natural Fiber Integrity.

- What role do molds play in the formation of Ruthenium sheets? Master High-Density Ruthenium Fabrication

- What is the temperature range for compression molding? Optimize Your Process for Perfect Parts