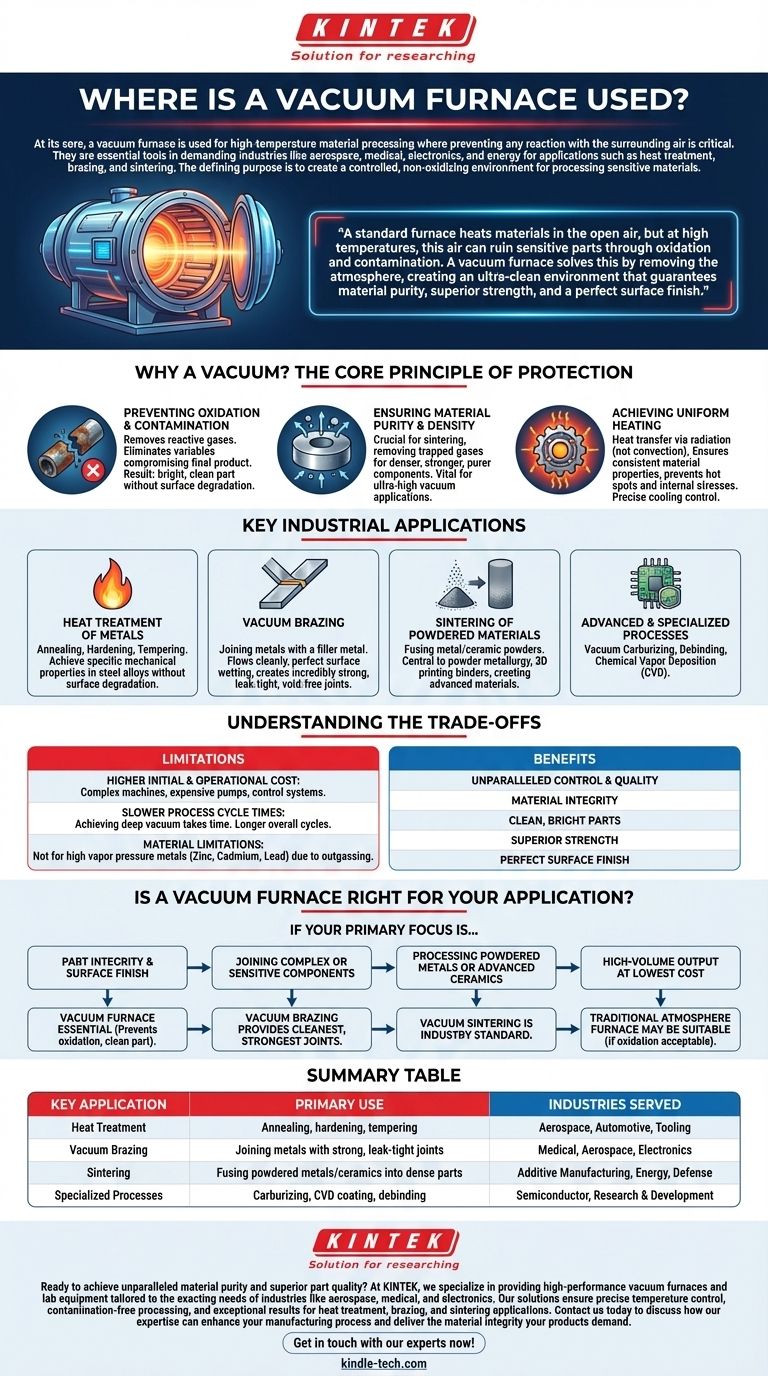

At its core, a vacuum furnace is used for high-temperature material processing where preventing any reaction with the surrounding air is critical. They are essential tools in demanding industries like aerospace, medical, electronics, and energy for applications such as heat treatment, brazing, and sintering. The defining purpose of a vacuum furnace is to create a controlled, non-oxidizing environment for processing sensitive materials.

A standard furnace heats materials in the open air, but at high temperatures, this air can ruin sensitive parts through oxidation and contamination. A vacuum furnace solves this by removing the atmosphere, creating an ultra-clean environment that guarantees material purity, superior strength, and a perfect surface finish.

Why a Vacuum? The Core Principle of Protection

The decision to use a vacuum furnace is driven by the need for absolute control over the processing environment. By removing the reactive gases found in air, you eliminate variables that can compromise the final product.

Preventing Oxidation and Contamination

At high temperatures, most metals will react with oxygen in the air, forming an oxide layer on the surface. This can range from simple discoloration to a brittle scale that weakens the part and requires costly secondary cleaning operations.

A vacuum furnace pumps out nearly all of the oxygen and other atmospheric gases, creating a space where materials can be heated without these unwanted chemical reactions. The result is a bright, clean part straight out of the furnace.

Ensuring Material Purity and Density

The vacuum environment is also crucial for processes like sintering, where powdered metals or ceramics are fused into a solid mass. The vacuum helps remove trapped gases from within the powder, leading to a denser, stronger, and more pure final component.

This process, known as outgassing, is also vital for purifying certain materials and preparing components for ultra-high vacuum applications like X-ray tubes or particle accelerators.

Achieving Uniform Heating

In a vacuum, heat transfer occurs primarily through radiation, not convection (air currents). This allows for exceptionally uniform heating across the entire part, even for complex geometries.

This uniformity prevents hot spots and internal stresses, ensuring that the material's properties are consistent throughout. Cooling can also be precisely controlled by backfilling the chamber with a specific amount of inert gas like nitrogen or argon.

Key Industrial Applications

Vacuum technology enables a range of processes that would be impossible or impractical in a conventional furnace. These applications are defined by their need for high quality and repeatability.

Heat Treatment of Metals

This is one of the most common uses. Processes like annealing (softening), hardening (quenching), and tempering are performed in a vacuum to achieve specific mechanical properties in steel alloys and other metals without surface degradation.

Vacuum Brazing

Brazing is a process for joining two pieces of metal using a filler metal that melts at a lower temperature. In a vacuum, the filler metal flows cleanly and wets the surfaces perfectly, creating an incredibly strong, leak-tight joint free of voids.

This is critical for manufacturing aerospace components like turbine blades, medical implants, and microchannel heat exchangers.

Sintering of Powdered Materials

Vacuum furnaces are the standard for sintering both metal and ceramic powders. This process is central to powder metallurgy, 3D printing binders, and creating advanced materials like ceramic armor, cermets, and carbon-carbon composites.

Advanced and Specialized Processes

The controlled environment of a vacuum furnace is also used for highly specialized applications, including:

- Vacuum Carburizing: A case-hardening process that introduces carbon into the surface of steel for enhanced wear resistance.

- Debinding: The removal of polymer binders from parts made via metal injection molding (MIM) before the final sintering step.

- Chemical Vapor Deposition (CVD): Applying thin-film coatings to a substrate material.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the solution for every heating application. Understanding their limitations is key to making an informed decision.

Higher Initial and Operational Cost

Vacuum furnaces are complex machines. The robust chamber, powerful vacuum pumps, and sophisticated control systems make them significantly more expensive to purchase and operate than standard atmosphere furnaces.

Slower Process Cycle Times

Achieving a deep vacuum is not instantaneous. The time required to pump down the chamber, run the heating cycle, and cool the load often results in longer overall cycle times compared to processing in air or a simple inert atmosphere.

Material Limitations

Not all materials are suitable for vacuum processing. Metals with a high vapor pressure, such as zinc, cadmium, or lead, can vaporize (outgas) under vacuum at high temperatures. This can contaminate both the furnace interior and the part itself.

Is a Vacuum Furnace Right for Your Application?

Choosing the right thermal processing equipment depends entirely on the requirements of your final product.

- If your primary focus is part integrity and surface finish: A vacuum furnace is essential to prevent oxidation and deliver a clean, bright part that requires no secondary finishing.

- If your primary focus is joining complex or sensitive components: Vacuum brazing provides the cleanest, strongest, and most reliable joints, which is non-negotiable for critical applications.

- If your primary focus is processing powdered metals or advanced ceramics: Vacuum sintering is the industry standard for achieving the highest possible density, purity, and strength in the final component.

- If your primary focus is high-volume output at the lowest cost: A traditional atmosphere furnace may be more suitable, provided your material can tolerate some surface oxidation or if a secondary cleaning step is acceptable.

Ultimately, choosing a vacuum furnace is an investment in unparalleled control, quality, and material integrity.

Summary Table:

| Key Application | Primary Use | Industries Served |

|---|---|---|

| Heat Treatment | Annealing, hardening, tempering | Aerospace, Automotive, Tooling |

| Vacuum Brazing | Joining metals with strong, leak-tight joints | Medical, Aerospace, Electronics |

| Sintering | Fusing powdered metals/ceramics into dense parts | Additive Manufacturing, Energy, Defense |

| Specialized Processes | Carburizing, CVD coating, debinding | Semiconductor, Research & Development |

Ready to achieve unparalleled material purity and superior part quality?

At KINTEK, we specialize in providing high-performance vacuum furnaces and lab equipment tailored to the exacting needs of industries like aerospace, medical, and electronics. Our solutions ensure precise temperature control, contamination-free processing, and exceptional results for heat treatment, brazing, and sintering applications.

Contact us today to discuss how our expertise can enhance your manufacturing process and deliver the material integrity your products demand.

Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing

- Why is a 1000°C+ furnace needed for LLZO/LLTO? Mastering High-Temperature Sintering for Ceramic Electrolytes

- How do furnaces contribute to sodium battery cathode performance? Mastering Solid-State Synthesis for Energy Storage

- What are the disadvantages of vacuum heat treatment? High Costs and Technical Limitations Explained

- What are the advantages of using a vacuum drying oven for combustible cartridge cases? Enhance Safety and Quality

- How does thermal decomposition in furnaces influence MOCTAs? Optimize Anode Durability and Conductivity

- What is the use of a pyrolysis plant? Transform Waste into Fuel and Valuable Products

- What is vacuum furnace heat treatment? Achieve Superior, Contamination-Free Metal Strengthening