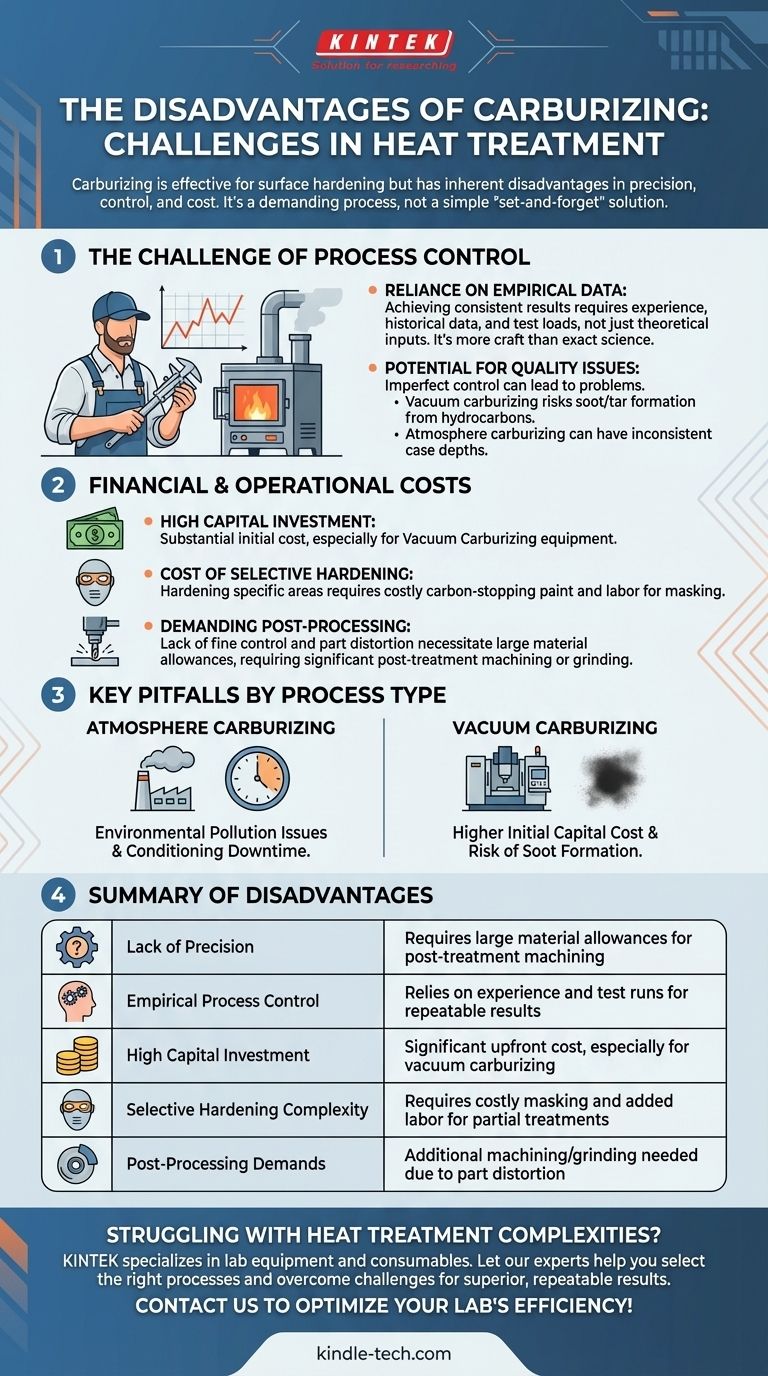

A primary disadvantage of the carburizing process is its inherent lack of precision, which leads to significant operational challenges. The process often requires large material allowances for post-treatment machining, relies heavily on empirical experience to achieve repeatable results, and can be costly and labor-intensive if only specific areas of a part need to be hardened.

While effective for creating a hard surface case on steel parts, carburizing is not a simple, "set-and-forget" solution. Its core disadvantages stem from a combination of high costs, complex process control, and the necessity for significant post-processing work.

The Challenge of Process Control

One of the most significant drawbacks of carburizing is the difficulty in achieving precise, repeatable results without considerable effort. This challenge manifests in several ways.

Reliance on Empirical Data

Both atmosphere and vacuum carburizing are not purely theoretical processes. Achieving the desired case depth and hardness consistently requires empirically gained experience.

This means operators must run test loads or rely on historical data to determine the optimum settings for factors like time, temperature, and gas pressure. It is less a science of exact inputs and more a craft refined through trial and error.

Potential for Quality Issues

Imperfect process control can lead directly to quality problems. In vacuum carburizing, incorrect management of the hydrocarbon gas can result in the formation of soot and tar, contaminating both the equipment and the parts.

In atmosphere carburizing, operators may struggle with case depth quality issues, where the hardened layer is either too deep, too shallow, or inconsistent across the part surface.

Understanding the Financial and Operational Costs

Beyond the technical challenges, carburizing carries significant direct and indirect costs that must be factored into any manufacturing decision.

High Capital Investment

The initial equipment cost, particularly for vacuum carburizing, can be very high. This represents a substantial capital investment that may not be justifiable for all operations.

The Cost of Selective Hardening

While carburizing is efficient for hardening the entire surface of a part, it becomes less so for selective hardening. If only specific areas need to be treated, the untreated surfaces must be masked with special carbon-stopping paint, adding material and labor costs to the process.

Demanding Post-Processing

Because the process can cause distortion and lacks fine control, parts are often manufactured with large material allowances. This extra material must be machined or ground away after heat treatment to achieve the final required dimensions, adding significant time and cost.

Key Disadvantages by Process Type

While many challenges are common, some disadvantages are more pronounced in one type of carburizing than another. This distinction is critical when selecting a specific method.

Atmosphere Carburizing Pitfalls

This common method requires constant monitoring of environmental pollution issues. Furthermore, if the equipment is shut down or idled, it must be properly conditioned before processing work, adding to operational downtime.

Vacuum Carburizing Pitfalls

The primary hurdle for vacuum carburizing is the higher initial capital equipment cost. While it offers more control than atmosphere methods, the process is still empirically driven and carries the risk of soot formation if not managed perfectly.

Making the Right Choice for Your Goal

Understanding these disadvantages is key to determining if carburizing is the correct process for your application.

- If your primary focus is cost-effective, bulk hardening of entire parts: Atmosphere carburizing is a viable option, but you must budget for significant post-processing and operational oversight.

- If your primary focus is hardening only specific areas of a component: Be aware that the required masking makes carburizing more complex and costly, potentially making alternative methods like induction hardening more suitable.

- If your primary focus is achieving high-quality, repeatable results with minimal contamination: Vacuum carburizing may be necessary, but this requires a major capital investment and deep process expertise.

Ultimately, choosing carburizing means accepting a powerful but demanding process that requires a significant investment in equipment, time, and skill to master.

Summary Table:

| Disadvantage | Impact |

|---|---|

| Lack of Precision | Requires large material allowances for post-treatment machining |

| Empirical Process Control | Relies on experience and test runs for repeatable results |

| High Capital Investment | Significant upfront cost, especially for vacuum carburizing |

| Selective Hardening Complexity | Requires costly masking and added labor for partial treatments |

| Post-Processing Demands | Additional machining/grinding needed due to part distortion |

Struggling with the complexities of heat treatment? KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the right equipment and processes to overcome the challenges of carburizing and other heat treatment methods. Contact us today to optimize your lab's efficiency and achieve superior, repeatable results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- Why would you braze instead of weld? Preserve Material Integrity and Join Dissimilar Metals

- What is the difference between welding and vacuum brazing? Choose the Right Joining Method for Your Project

- What metals can be joined by brazing? Discover the Versatility of Modern Brazing Techniques

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints

- Can you braze two different metals? Yes, and here’s how to do it successfully.