For the synthesis of single-wall carbon nanotubes, the most widely used and commercially dominant method is Chemical Vapor Deposition (CVD). While historical techniques like arc-discharge and laser ablation were pivotal in the discovery and early research of nanotubes, CVD has surpassed them due to its superior scalability and precise control over the final product.

While several methods can produce carbon nanotubes, Chemical Vapor Deposition (CVD) is the industry standard. Its dominance stems from its unique ability to balance production scale, cost-effectiveness, and precise control over the nanotube's structure and quality.

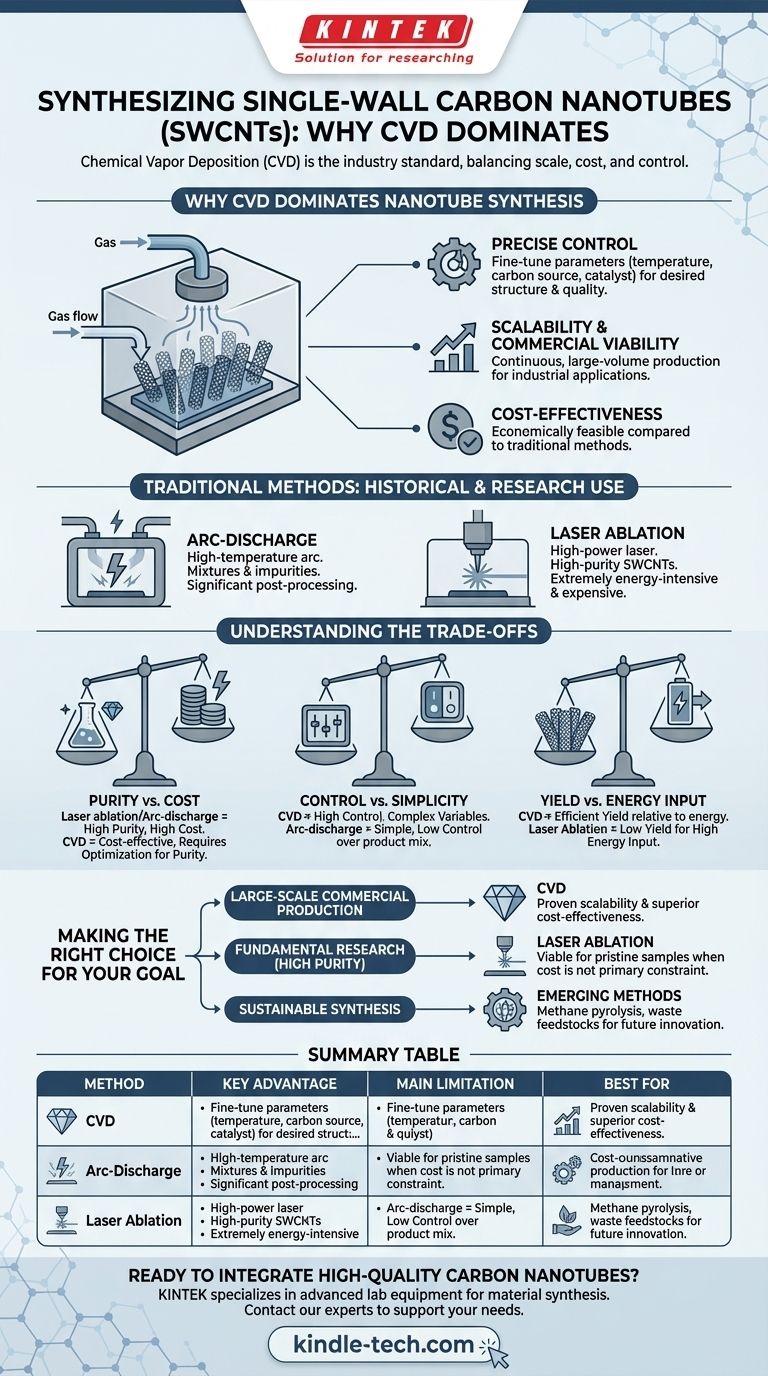

Why CVD Dominates Nanotube Synthesis

Chemical Vapor Deposition is not just the most common method; it is the most practical for a majority of modern applications. Its widespread adoption is rooted in a few key advantages over traditional techniques.

Control Over Quality and Properties

CVD is highly valued because it allows for the production of high-quality materials with desired properties. This is because the critical operating parameters of the synthesis process can be finely tuned.

Engineers can precisely adjust factors like temperature, carbon source concentration, and catalyst residence time to influence the final structure, diameter, and purity of the carbon nanotubes.

Scalability and Commercial Viability

CVD is the dominant commercial process for a reason. Unlike arc-discharge or laser ablation, CVD processes can be scaled up for continuous, large-volume production, making it economically feasible for industrial applications.

This scalability is what has enabled carbon nanotubes to move from the research lab into commercial products.

The Traditional Synthesis Methods

To understand why CVD is superior, it's useful to know the methods it replaced. These traditional techniques are still used in specific research contexts but are not suitable for large-scale production.

Arc-Discharge

This was one of the original methods for producing carbon nanotubes. It involves creating a high-temperature electric arc between two graphite electrodes, which vaporizes the carbon.

While it can produce high-quality nanotubes, the output is often a mixture of different structures (single-walled, multi-walled) and impurities that require significant post-processing to separate.

Laser Ablation

In this technique, a high-power laser is used to vaporize a graphite target that has been doped with a metal catalyst. The vaporized carbon then condenses into nanotubes.

Laser ablation can produce a high yield of high-purity single-wall carbon nanotubes, but the process is extremely energy-intensive and expensive, limiting its use to small-scale research.

Understanding the Trade-offs

Choosing a synthesis method involves balancing competing priorities. No single method is perfect for every scenario, and understanding the trade-offs is key to making an informed decision.

Purity vs. Cost

Laser ablation and arc-discharge can produce very high-purity material, but at a significant cost in both energy and equipment. CVD offers a much more cost-effective pathway, though achieving the absolute highest levels of purity can require extensive process optimization.

Control vs. Simplicity

The strength of CVD is its high degree of control. However, this also means the process has more variables that must be managed. Methods like arc-discharge are conceptually simpler but offer very little control over the final product mix.

Yield vs. Energy Input

CVD is a more efficient process in terms of the amount of nanotubes produced relative to the energy and raw materials consumed. Laser ablation, in particular, has a very low yield for its high energy input, making it impractical for anything beyond specialized lab work.

Making the Right Choice for Your Goal

The "best" synthesis method is entirely dependent on your objective. Your end goal dictates which trade-offs are acceptable.

- If your primary focus is large-scale commercial production: Chemical Vapor Deposition (CVD) is the only practical choice due to its proven scalability and superior cost-effectiveness.

- If your primary focus is fundamental research requiring small, high-purity samples: Laser ablation remains a viable, though expensive, option for producing pristine material when cost is not the main constraint.

- If your primary focus is sustainable synthesis: Exploring emerging methods like methane pyrolysis or using waste feedstocks will be critical for future-focused and environmentally conscious innovation.

Ultimately, selecting the right synthesis method depends on balancing the required quality, desired quantity, and available budget for your specific application.

Summary Table:

| Method | Key Advantage | Main Limitation | Best For |

|---|---|---|---|

| Chemical Vapor Deposition (CVD) | Superior scalability & control | Requires process optimization | Large-scale commercial production |

| Arc-Discharge | Can produce high-quality nanotubes | Low yield, mixture of by-products | Historical research, small batches |

| Laser Ablation | High-purity single-wall nanotubes | Extremely energy-intensive & expensive | Small-scale, high-purity research |

Ready to integrate high-quality carbon nanotubes into your research or product development?

At KINTEK, we specialize in providing the advanced lab equipment and consumables needed for cutting-edge material synthesis. Whether you're scaling up with CVD or pursuing high-purity research, our expertise can help you achieve precise, reliable results.

Contact our experts today via our Contact Form to discuss how we can support your laboratory's specific needs and drive your innovations forward.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance