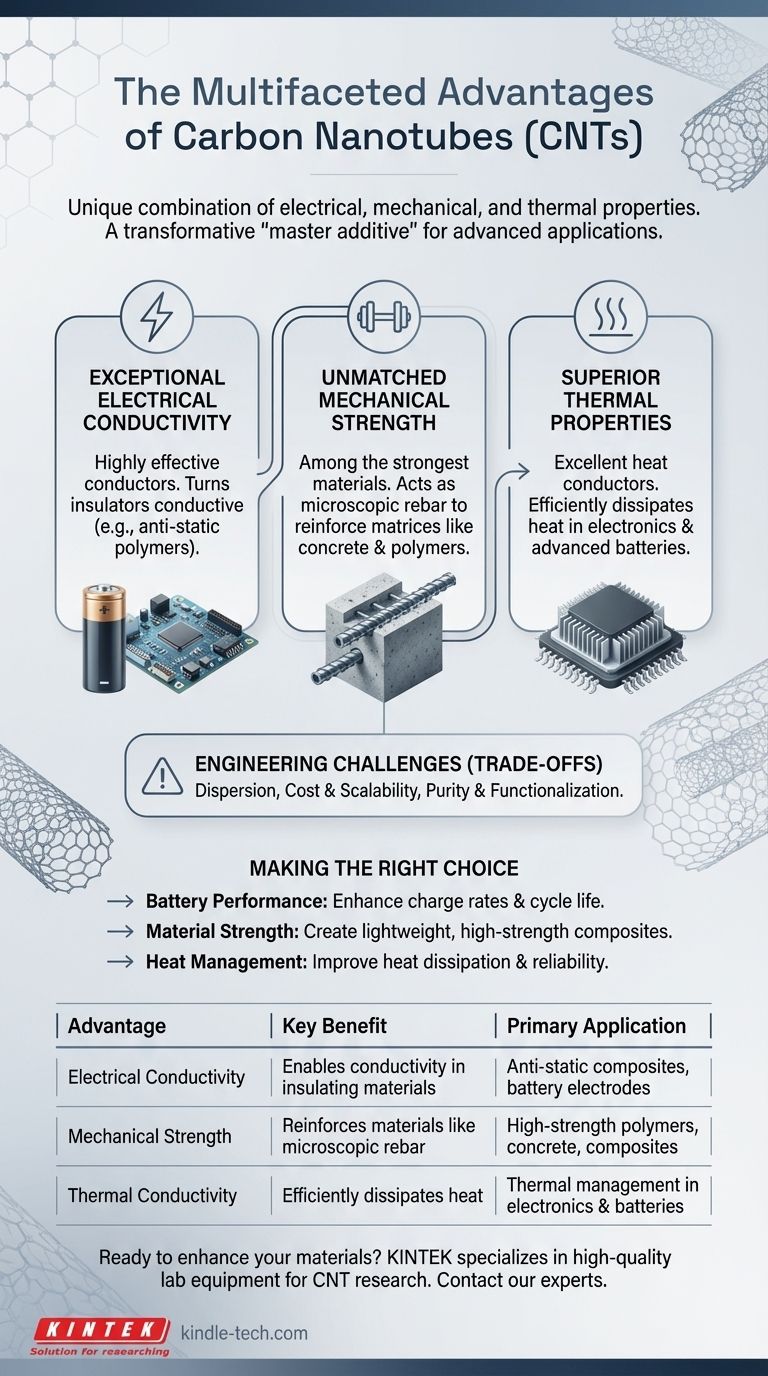

At their core, the primary advantage of carbon nanotubes (CNTs) lies in their unique and exceptional combination of electrical, mechanical, and thermal properties. These atomically thin rolled-up sheets of graphene are not just good at one thing; they excel in multiple domains simultaneously, making them a transformative additive material for a vast range of advanced applications.

The true power of carbon nanotubes is not found in a single benefit, but in their versatility. They act as a "master additive," capable of simultaneously enhancing the conductivity, strength, and thermal stability of host materials like polymers, metals, and battery components.

The Core Advantages: A Multifaceted Profile

To understand the value of CNTs, we must look at their individual properties. Each one unlocks a different set of potential applications, but it is their combined effect that is truly revolutionary.

Exceptional Electrical Conductivity

Carbon nanotubes are highly effective electrical conductors. Their structure allows electrons to move with very little resistance, a property that is critical in modern technology.

This makes them an ideal additive for turning insulating materials into conductive ones. For example, adding a very small amount of CNTs to a polymer can make it suitable for preventing electrostatic discharge.

Unmatched Mechanical Strength

On a pound-for-pound basis, carbon nanotubes are one of the strongest and stiffest materials ever discovered. Their tensile strength and elastic modulus far exceed that of steel.

When dispersed into a host material like concrete or a polymer, they act like microscopic rebar, reinforcing the matrix and significantly increasing its overall strength and durability.

Superior Thermal Properties

CNTs are also excellent thermal conductors. They can efficiently transfer heat, a crucial attribute for managing thermal performance in high-power electronics and batteries.

This ability to dissipate heat helps prevent component failure and improves the safety and lifespan of devices where thermal management is a primary concern, such as in processors or advanced battery systems.

Understanding the Trade-offs

While their properties are exceptional, leveraging CNTs effectively comes with significant engineering challenges. Objectivity requires acknowledging these limitations.

The Challenge of Dispersion

The single greatest hurdle in using CNTs is achieving a uniform dispersion. Due to strong attractive forces, nanotubes tend to clump together, forming agglomerates.

These clumps not only fail to impart their beneficial properties but can also create weak points within the host material, degrading performance instead of enhancing it.

Cost and Scalability

The production of high-purity, specific types of carbon nanotubes can be complex and expensive. This cost factor has historically limited their use to high-value applications.

While manufacturing processes are improving and costs are decreasing, large-scale industrial adoption still faces economic barriers compared to conventional additives.

Purity and Functionalization

The performance of CNTs is highly sensitive to impurities, such as residual metal catalysts left over from the manufacturing process. These impurities can negatively impact electrical and chemical properties.

Furthermore, for many applications, the surface of the CNTs must be chemically modified (functionalized) to ensure they bond properly with the host material, adding another layer of processing complexity.

Making the Right Choice for Your Goal

The decision to use carbon nanotubes must be driven by a clear understanding of the problem you are trying to solve.

- If your primary focus is improving battery performance: Use CNTs as a conductive additive in cathode and anode materials to enhance charge rates and cycle life.

- If your primary focus is enhancing material strength: Incorporate CNTs into composites like polymers or concrete to create lightweight, high-strength structural materials.

- If your primary focus is managing heat in electronics: Leverage CNTs in thermal interface materials or heat sinks to improve heat dissipation and device reliability.

Ultimately, carbon nanotubes offer a powerful toolkit for solving some of today's most difficult materials science and engineering challenges.

Summary Table:

| Advantage | Key Benefit | Primary Application |

|---|---|---|

| Electrical Conductivity | Enables conductivity in insulating materials | Anti-static composites, battery electrodes |

| Mechanical Strength | Reinforces materials like microscopic rebar | High-strength polymers, concrete, composites |

| Thermal Conductivity | Efficiently dissipates heat | Thermal management in electronics & batteries |

Ready to enhance your materials with the power of carbon nanotubes?

KINTEK specializes in providing high-quality lab equipment and consumables for advanced materials research and development. Whether you are developing next-generation batteries, stronger composites, or more efficient thermal management systems, our solutions can help you integrate CNT technology effectively.

Contact our experts today to discuss how we can support your specific laboratory needs and accelerate your innovation.

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Multi-zone Laboratory Tube Furnace

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the disadvantages of brazing? Understanding the key limitations and trade-offs.

- How do porcelain boats and quartz tubes function in CVD of BN? Optimize Your Boron Nitride Coating Efficiency

- What are ceramic tubes used for? Essential for Extreme Heat, Insulation & Purity

- What are the strengths of brazing? Achieve Strong, Clean, and Precise Metal Joining

- What are 4 disadvantages of brazing? Understanding the Critical Limitations of This Joining Method