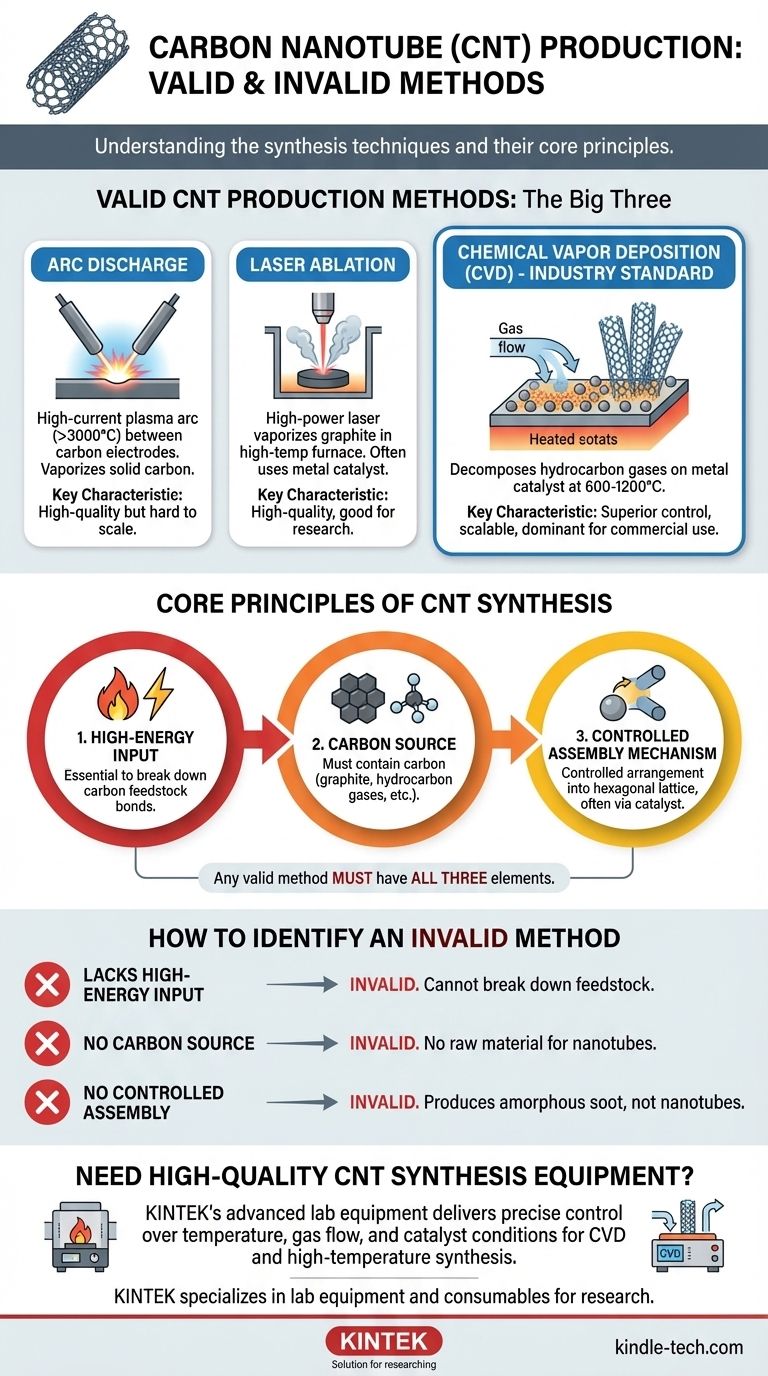

To identify which method cannot be used for producing carbon nanotubes, you must first understand the ones that can. The three primary, established methods for CNT synthesis are arc discharge, laser ablation, and chemical vapor deposition (CVD), with CVD being the most dominant for commercial production. Emerging techniques also include methane pyrolysis and the electrolysis of CO2 in molten salts.

The synthesis of carbon nanotubes is fundamentally a process of transforming a carbon source into a highly structured graphitic form. Any valid method must provide a high-energy environment to break down the feedstock and a controlled mechanism for the carbon atoms to reassemble into tubes, often with the help of a metal catalyst.

Foundational High-Temperature Methods

The earliest successful methods for producing carbon nanotubes relied on extreme temperatures to vaporize a solid carbon source. These techniques are effective for creating high-quality material but are often difficult to scale.

Arc Discharge

In the arc discharge method, a very high electric current is passed between two carbon electrodes in an inert gas atmosphere.

This creates an extremely hot plasma arc (over 3000°C) that vaporizes the carbon from the positive electrode (anode). The vaporized carbon then cools and condenses on the negative electrode (cathode), forming carbon nanotubes.

Laser Ablation

This technique uses a high-power laser to vaporize a graphite target inside a high-temperature furnace.

As the vaporized carbon is carried away by a flow of inert gas, it cools and self-assembles into nanotubes. Metal catalyst particles are often mixed into the graphite target to facilitate and control the growth.

The Dominant Commercial Process: CVD

While the foundational methods are effective, Chemical Vapor Deposition (CVD) has become the industry standard due to its superior control and scalability.

How Chemical Vapor Deposition (CVD) Works

CVD is a "bottom-up" approach. A carbon-containing gas, such as methane or acetylene, is introduced into a reaction chamber.

The gas decomposes at high temperatures (typically 600-1200°C) over a substrate coated with metal catalyst nanoparticles (e.g., iron, nickel, cobalt). The carbon atoms then assemble into tube structures on these catalyst sites.

Why CVD is the Industry Standard

The primary advantage of CVD is its control. By carefully managing parameters like temperature, gas flow, and catalyst size, manufacturers can influence the diameter, length, and even the alignment of the nanotubes being grown. This makes it far more suitable for large-scale, consistent production.

Understanding the Core Principles

To determine if a proposed method is valid, you must check if it meets the fundamental requirements for nanotube synthesis. Any method that fails these checks cannot be used.

The Need for a High-Energy Input

All successful synthesis techniques require a significant energy input—whether from a plasma arc, a laser, or a furnace.

This energy is essential to break the chemical bonds of the carbon feedstock (e.g., graphite or a hydrocarbon gas) and create a supply of free carbon atoms ready for assembly.

The Requirement of a Carbon Source

This may seem obvious, but the process must start with a suitable carbon-containing material.

Valid feedstocks include solid graphite, hydrocarbon gases (methane, ethylene), and even waste sources like carbon dioxide or certain plastics under the right conditions. A method proposing to use a non-carbon source is inherently invalid.

The Mechanism for Controlled Assembly

Simply creating a cloud of hot carbon atoms is not enough; this would just produce soot (amorphous carbon).

A valid process must provide a controlled environment where these atoms can arrange themselves into the specific hexagonal lattice structure of a nanotube. This is often the role of the metal catalyst particles, which act as templates for growth.

How to Identify an Invalid Production Method

When evaluating a potential synthesis technique, consider the following points to determine its viability.

- If the proposed method lacks a high-energy input: It is invalid, as breaking down the carbon feedstock is the non-negotiable first step.

- If the method does not involve a suitable carbon source: It cannot be used, as there is no raw material from which to build the nanotubes.

- If the process lacks a mechanism for controlled atomic assembly: It will likely produce disordered, amorphous carbon rather than highly structured nanotubes.

Understanding these core physical requirements is the key to distinguishing viable synthesis techniques from impossible ones.

Summary Table:

| Valid CNT Production Methods | Key Characteristics |

|---|---|

| Arc Discharge | Uses a high-current plasma arc (>3000°C) to vaporize a solid carbon electrode. |

| Laser Ablation | Vaporizes a graphite target with a high-power laser in a high-temperature furnace. |

| Chemical Vapor Deposition (CVD) | Decomposes hydrocarbon gases on a metal catalyst at 600-1200°C; the industry standard. |

| Key Principle for Any Valid Method | Must provide high energy, a carbon source, and a mechanism for controlled atomic assembly. |

Need High-Quality CNT Synthesis Equipment?

Producing carbon nanotubes reliably requires precise control over temperature, gas flow, and catalyst conditions—exactly what KINTEK's advanced lab equipment delivers. Our Chemical Vapor Deposition (CVD) systems and high-temperature furnaces are engineered to meet the rigorous demands of CNT research and development.

KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories like yours. Let us help you optimize your synthesis process.

Contact our experts today to discuss your specific requirements and discover the right solution for your lab.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication