In short, ball mills are a cornerstone technology used across a vast spectrum of industries for grinding and blending materials. Key users include heavy industries like mining and cement production, precision fields such as ceramics and pharmaceuticals, and foundational work in research and development laboratories.

The universal appeal of the ball mill isn't just its ability to grind materials into fine powders. Its true value lies in its remarkable versatility and process control, allowing industries from heavy mining to sterile pharmaceuticals to achieve precise particle reduction in a sealed, controlled environment.

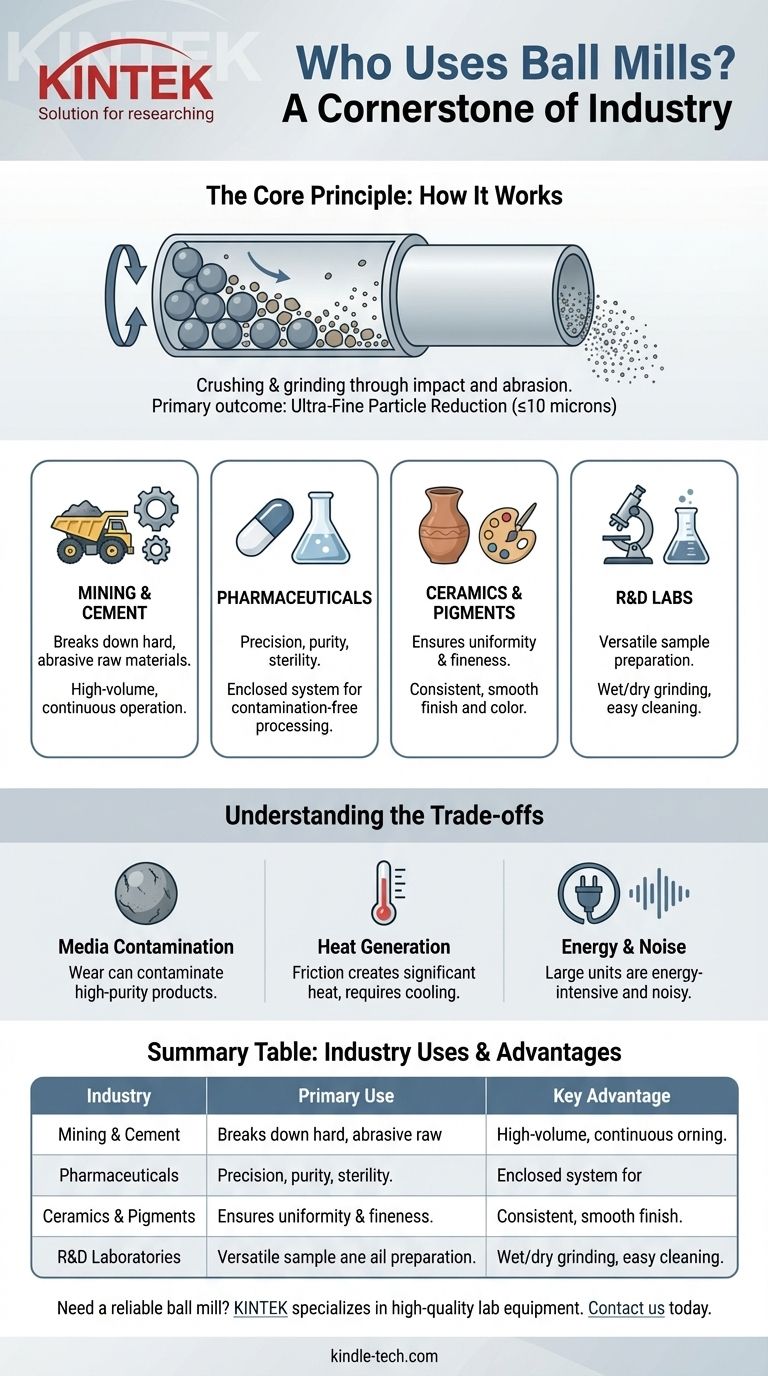

The Core Principle: Why a Ball Mill is So Effective

A ball mill is fundamentally a simple but powerful tool. Understanding its core function reveals why so many different sectors rely on it.

How It Works

A ball mill consists of a hollow cylinder that rotates on its axis. This cylinder is partially filled with the material to be ground, along with a grinding medium—typically hard balls made of steel, ceramic, or rubber.

As the cylinder turns, the balls are lifted up the side and then cascade or tumble back down, crushing and grinding the material through impact and abrasion.

The Primary Outcome: Ultra-Fine Particle Reduction

The primary goal of this process is to achieve significant size reduction. Ball mills are highly effective at producing extremely fine powders, often with particle sizes of 10 microns or less.

This level of fineness is critical for increasing the surface area of a material, which can improve chemical reaction rates, create smoother mixtures, and ensure product consistency.

A Breakdown of Key Industrial Users

The advantages of a ball mill directly address the specific challenges faced by different industries.

Mining and Cement Production

In these heavy industrial settings, the main task is breaking down large, hard, and abrasive raw materials like ores and clinker.

The ball mill is ideal here due to its suitability for continuous operation and its sheer power in milling abrasive materials efficiently on a massive scale.

The Pharmaceutical Sector

Pharmaceutical manufacturing requires precision, purity, and safety. A ball mill's enclosed container system is a significant advantage.

This design prevents contamination, making it perfect for maintaining the sterility of parenteral (injectable) and ophthalmic (eye-related) products. It also allows for the safe grinding of highly potent or toxic materials without exposing operators.

Ceramics and Pigments

For ceramics, paints, and pigments, the final product's quality depends on the uniformity and fineness of the constituent powders.

A ball mill delivers the consistent, fine particle size needed to ensure a smooth finish, uniform color, and predictable material properties.

Research and Development Labs

In a laboratory setting, versatility is key. Researchers use ball mills to prepare a wide variety of material samples for analysis.

The advantages here include a relatively small installation footprint, the ability to perform both wet and dry grinding, and the ease of cleaning between experiments with different materials.

Understanding the Trade-offs

While highly effective, the ball mill is not without its operational considerations. Objectivity requires acknowledging its limitations.

Potential for Media Contamination

The grinding media (the balls themselves) are subject to wear. Over time, small particles from the media can break off and contaminate the product being milled.

This is a critical concern in high-purity applications, such as pharmaceuticals or electronics, and requires careful selection of grinding media material.

Heat Generation

The constant friction and impact inside the mill generate significant heat. For heat-sensitive materials, this can lead to degradation, melting, or unwanted chemical changes. Cooling systems or controlled milling cycles are often necessary to mitigate this.

Energy and Noise

While smaller lab units are efficient, large industrial ball mills are energy-intensive machines that can generate considerable noise, requiring soundproofing and safety measures in the plant environment.

Making the Right Choice for Your Application

Selecting the right grinding technology depends entirely on your primary goal.

- If your primary focus is large-scale reduction of hard, abrasive materials: The ball mill is an industry standard for its durability and suitability for continuous, high-volume operation.

- If your primary focus is product purity and sterility: A ball mill's enclosed system is ideal, but you must carefully select non-contaminating grinding media to avoid compromising the final product.

- If your primary focus is creating ultra-fine, consistent powders for quality-critical products: The ball mill provides excellent control over final particle size, essential for ceramics, pigments, and advanced materials.

Ultimately, the ball mill's enduring relevance comes from its simple design and profound ability to meet the precise material processing needs of vastly different fields.

Summary Table:

| Industry | Primary Use of Ball Mill | Key Advantage |

|---|---|---|

| Mining & Cement | Grinding hard, abrasive ores & clinker | High-volume, continuous operation |

| Pharmaceuticals | Milling sterile, potent, or toxic materials | Enclosed, contamination-free system |

| Ceramics & Pigments | Creating fine, uniform powders | Consistent particle size for quality |

| R&D Laboratories | Preparing diverse material samples | Versatile wet/dry grinding, easy cleaning |

Need a reliable ball mill for your specific application? KINTEK specializes in high-quality lab equipment, including ball mills tailored for industries like pharmaceuticals, ceramics, and mining. Our experts will help you select the right solution for precise grinding, contamination control, and efficient operation. Contact us today to discuss your requirements and enhance your material processing workflow!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- What is the key role of a planetary ball mill for IZO targets? Achieve Atomic-Level Uniformity in Material Preparation

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding