In short, porcelain is fired under a vacuum to remove air and other gases from between the powder particles before they fuse together. This process is essential for eliminating internal bubbles, known as porosity. The result is a final product that is significantly denser, stronger, and more translucent than one fired in a normal atmosphere.

The core purpose of vacuum firing is to solve the problem of trapped air. Heating porcelain powder in a normal atmosphere would trap expanding air bubbles within the material as it solidifies, creating a weak and opaque structure. A vacuum removes this air, allowing the particles to fuse into a near-perfectly solid mass.

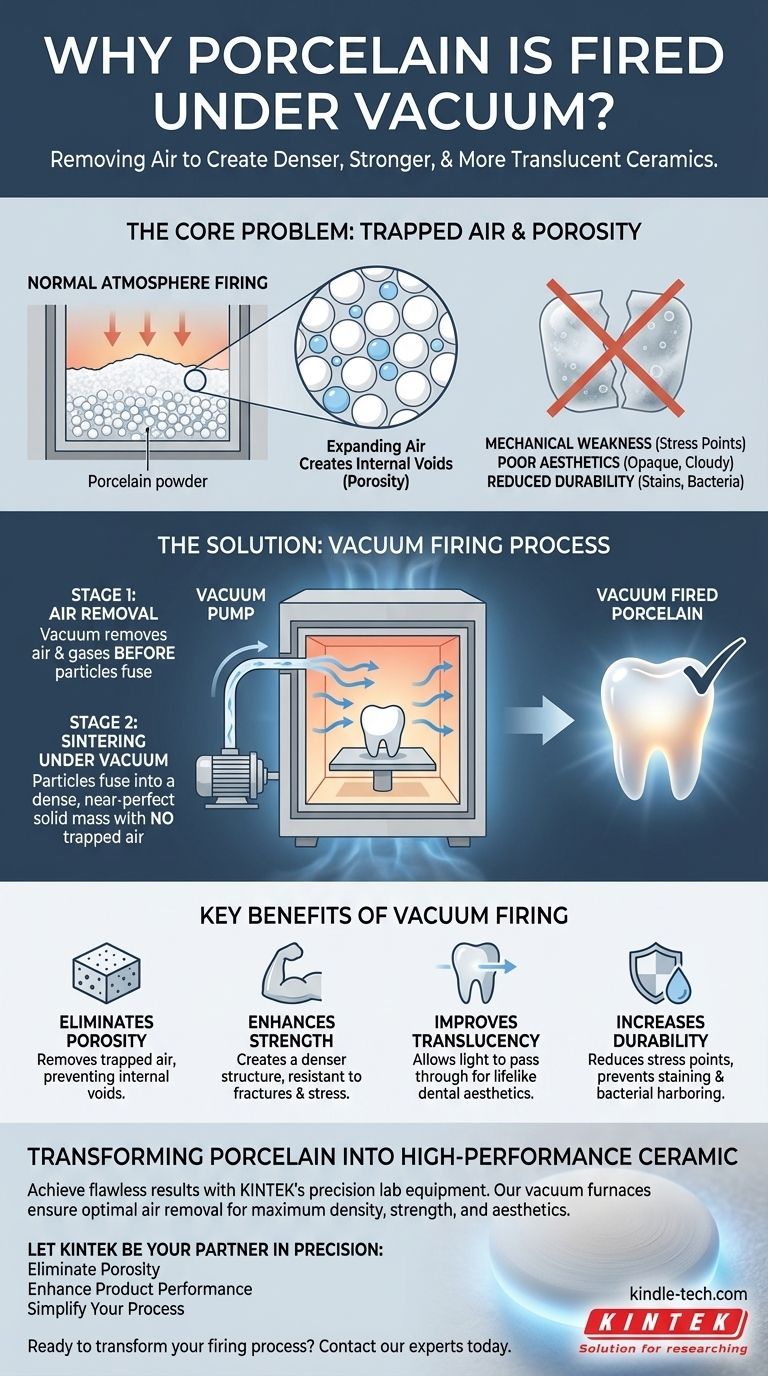

The Core Problem: Trapped Air and Porosity

To understand why a vacuum is necessary, we must first understand the fundamental process of firing porcelain, known as sintering.

What Is Sintering?

Sintering is the process of compacting and forming a solid mass of material by heat, without melting it to the point of liquefaction.

Porcelain starts as a fine powder. When heated, the individual particles begin to bond at their contact points, gradually fusing together and eliminating the gaps between them.

The Enemy Within: Porosity

The initial porcelain powder is not a solid block; it's a collection of tiny particles with air filling the microscopic spaces between them.

When this powder is heated in a normal atmosphere, that trapped air heats up and expands. As the porcelain particles begin to fuse and seal the outer surface, this expanding air becomes trapped, forming internal bubbles or voids. This internal void space is called porosity.

The Consequences of Porosity

Porosity is the primary defect in high-performance ceramics and has several destructive consequences:

- Mechanical Weakness: Pores act as stress concentration points. When the porcelain is under load, stress multiplies at the edge of these voids, making it the starting point for cracks and fractures.

- Poor Aesthetics: In applications like dental crowns, pores scatter light instead of allowing it to pass through. This makes the porcelain look cloudy and opaque, failing to mimic the natural translucency of tooth enamel.

- Reduced Durability: Pores on or near the surface can collect stains or harbor bacteria over time, compromising both hygiene and appearance.

How Vacuum Firing Solves the Problem

Applying a vacuum during a specific phase of the heating cycle directly counteracts the formation of porosity.

Removing Air Before It's Trapped

The vacuum pump removes the vast majority of the air and other gases from the furnace chamber before the porcelain particles reach a temperature where they begin to fuse.

With no air left to get trapped, the particles can sinter together into a much denser, more uniform structure.

Achieving Superior Density

By eliminating porosity, vacuum firing allows the porcelain to achieve a density that is very close to its theoretical maximum. A denser material is inherently a stronger material.

For high-stress applications, from dental bridges to high-voltage electrical insulators, achieving maximum density is critical for reliability and longevity.

Enhancing Translucency and Aesthetics

The most visible benefit, especially in dentistry, is the dramatic improvement in aesthetics.

Without pores to scatter light, the fired porcelain becomes highly translucent. This allows artisans and dental technicians to create crowns and veneers that perfectly replicate the depth, color, and vitality of a natural tooth.

Common Pitfalls and Considerations

While vacuum is essential, it is not a magic bullet. It is part of a precisely controlled process.

Why Not Just Fire in Air?

Firing porcelain in an atmospheric kiln is perfectly acceptable for applications where strength and translucency are not critical, such as decorative pottery or some tiles.

However, for any high-performance application, the resulting porosity from atmospheric firing would constitute a critical failure.

The Importance of the Firing Cycle

The vacuum is not applied during the entire firing process. It is typically introduced as the temperature rises and is released before the final, highest temperature is reached.

This precise control, known as the firing schedule, ensures gases are removed at the right time without causing other issues. An incorrect schedule, even with a perfect vacuum, can lead to poor results.

Equipment Integrity is Crucial

The effectiveness of the process depends entirely on the vacuum furnace's ability to maintain a strong, consistent vacuum.

Even a small leak in a door seal or hose can introduce enough air to compromise the entire firing, resulting in a cloudy or weak final product. Regular maintenance and calibration of the furnace are non-negotiable.

Making the Right Choice for Your Goal

Understanding the role of the vacuum helps you diagnose problems and appreciate the requirements for achieving a high-quality result.

- If your primary focus is dental aesthetics: Vacuum firing is the only way to achieve the life-like translucency and color matching required for modern crowns and veneers.

- If your primary focus is mechanical strength: Eliminating porosity through vacuum firing is the most critical step to prevent premature fractures and ensure long-term reliability under stress.

- If you are troubleshooting firing issues: The appearance of cloudiness, "whiteness," or internal voids in your porcelain almost always points to an issue with the vacuum system or the firing schedule.

Ultimately, vacuum firing transforms porcelain from a simple fused powder into a high-performance engineered ceramic.

Summary Table:

| Benefit | Result |

|---|---|

| Eliminates Porosity | Removes trapped air bubbles that cause internal voids |

| Enhances Strength | Creates a denser, more uniform structure resistant to fractures |

| Improves Translucency | Allows light to pass through for lifelike dental aesthetics |

| Increases Durability | Reduces stress points and prevents staining or bacterial harboring |

Achieve flawless porcelain results with KINTEK's precision lab equipment.

Whether you're in dental ceramics, industrial components, or advanced material research, our vacuum furnaces are engineered to deliver the consistent, high-quality outcomes you demand.

Let KINTEK be your partner in precision:

- Eliminate Porosity: Our reliable vacuum systems ensure optimal air removal for maximum density.

- Enhance Product Performance: Achieve the strength and aesthetics required for high-value applications.

- Simplify Your Process: Benefit from equipment designed for ease of use and dependable operation.

Ready to transform your porcelain firing process?

Contact our experts today via our Contact Form to discuss your specific needs and discover the perfect solution for your laboratory.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the difference between composite and ceramic restoration? Choosing the Right Material for Your Smile

- What are the disadvantages of all-ceramic restorations? Key Limitations for Long-Term Success

- How can consistent heating of ceramic restorations be achieved within a furnace? Master Your Furnace's Heat Dynamics

- What is an economical method for purging a porcelain furnace muffle? A Simple, High-Heat Cycle for Cleaner Dental Restorations

- What are the advantages of zirconia bridges? A Durable, Metal-Free Solution for a Natural Smile

- What is the sintering temperature of zirconia? Achieve Optimal Strength and Aesthetics

- What is dental ceramic made of? Discover the Science Behind Strong, Beautiful Teeth

- What is the disadvantage of dental ceramic? Balancing Aesthetics with Durability and Risk