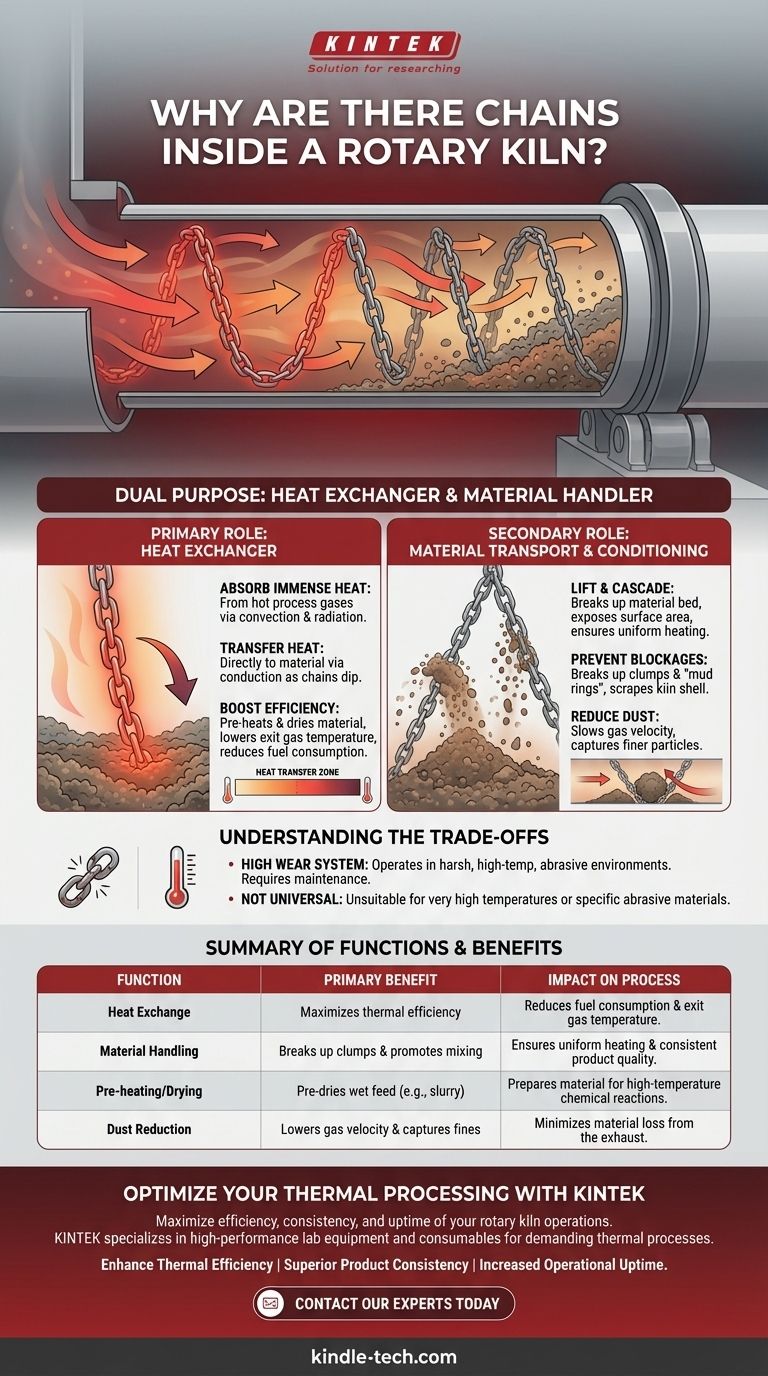

At their core, chains inside a rotary kiln serve a critical dual purpose: they function as a highly efficient internal heat exchanger and as a material handling system. They are designed to absorb immense heat from the hot process gases and transfer it directly to the raw material, while simultaneously guiding, breaking up, and mixing that material as it moves through the kiln.

The presence of chains is what elevates a rotary kiln from a simple heated cylinder to a highly optimized thermal processing unit. Their primary function is to maximize thermal efficiency by ensuring the heat generated by the burner is absorbed by the material, not wasted out the exhaust stack.

The Primary Role: A Massive Heat Exchanger

The most important function of a kiln chain system is to facilitate heat transfer between the hot gases flowing counter-current to the material feed. This dramatically improves the kiln's overall efficiency.

How Chains Transfer Heat

Chains are typically hung in dense curtains in the cooler, feed-end section of the kiln. As the kiln rotates, these chains are lifted through the hot gas stream, where they absorb heat through convection and radiation.

They then dip down into the bed of raw material, transferring this stored heat directly via conduction. This cycle repeats continuously, creating a massive surface area for heat exchange.

Driving Pre-heating and Drying

In many processes, such as wet-process cement manufacturing, the raw material enters as a wet slurry or "mud." The chain system's primary job here is to use the captured heat to evaporate this moisture.

This effectively pre-dries and preheats the feed before it reaches the hotter zones of the kiln where chemical reactions like calcination occur.

Boosting Thermal Efficiency

By capturing heat from the hot gas and transferring it to the feed, the chains significantly lower the temperature of the kiln's exit gas.

This means less energy is wasted, reducing the amount of fuel the burner needs to consume to achieve the target processing temperature. The chains, seals, and burner work as a system to achieve precise thermal control.

The Secondary Role: Material Transport and Conditioning

Beyond heat transfer, the physical action of the chains plays a vital role in preparing the material for processing.

Lifting and Cascading Material

The chains act as "lifters," scooping up material and showering it through the hot gas stream as the kiln rotates. This action, known as cascading, breaks up the solid bed of material.

Exposing more of the material's surface area to the hot gases further enhances convective heat transfer and ensures more uniform heating.

Preventing Blockages and Clumps

In processes involving sticky or clumpy feed, the continuous movement and weight of the chains help break up agglomerations.

This action prevents the formation of large "mud rings" or "balls" that can obstruct material flow, cause imbalances in the kiln, and lead to inconsistent product quality. They also help clean the kiln shell by scraping off adhered material.

Reducing Dust

By creating a curtain that the gas must pass through, the chain system can help reduce the velocity of the exiting gas stream. This can cause some of the finer particles (dust) to drop out of the gas and rejoin the material feed, reducing dust loss from the system.

Understanding the Trade-offs

While indispensable in many applications, chain systems are not without their challenges. They represent a significant engineering and maintenance consideration.

A Complex and High-Wear System

Chains operate in a harsh environment of high temperatures, abrasive materials, and potentially corrosive gases. They are subject to wear, stretching, and eventual failure.

The design of the chain system—including its density, length, and pattern—is critical. An poorly designed system can be inefficient or even cause material blockages, defeating its purpose.

Not a Universal Solution

Not all rotary kilns use or require chains. In very high-temperature applications, such as the burning zone of a cement kiln, the temperatures exceed the operational limits of metal chains.

Furthermore, some materials are too abrasive or have flow characteristics that make chain systems impractical. In these cases, different internal components like castable refractory lifters or simple bare shells are used.

Applying This to Your Goal

The function of the chain system directly impacts key operational objectives. Understanding this allows you to focus your attention on what matters most for your process.

- If your primary focus is thermal efficiency and cost reduction: The chain system is your most critical tool for capturing waste heat, lowering exit gas temperatures, and minimizing fuel consumption.

- If your primary focus is product quality and consistency: The chains' ability to lift, mix, and break up material ensures a uniform thermal treatment, which is essential for consistent product output.

- If your primary focus is operational stability and uptime: Proper inspection and maintenance of the chain system are non-negotiable to prevent ring formation, blockages, and costly unplanned shutdowns.

Ultimately, the chains transform the rotary kiln from a simple heated tube into a sophisticated and efficient processing machine.

Summary Table:

| Function | Primary Benefit | Impact on Process |

|---|---|---|

| Heat Exchange | Maximizes thermal efficiency | Reduces fuel consumption & exit gas temperature |

| Material Handling | Breaks up clumps & promotes mixing | Ensures uniform heating & consistent product quality |

| Pre-heating/Drying | Pre-dries wet feed (e.g., slurry) | Prepares material for high-temperature chemical reactions |

| Dust Reduction | Lowers gas velocity & captures fines | Minimizes material loss from the exhaust |

Optimize Your Thermal Processing with KINTEK

Are you looking to maximize the efficiency, consistency, and uptime of your rotary kiln operations? The intricate design of internal components like chain systems is critical to your success.

At KINTEK, we specialize in high-performance lab equipment and consumables tailored for demanding thermal processes. Whether you are developing new materials, optimizing production, or ensuring quality control, our solutions are designed to meet the precise needs of your laboratory.

Let us help you achieve:

- Enhanced Thermal Efficiency: Reduce energy costs and improve heat transfer.

- Superior Product Consistency: Ensure uniform processing for reliable results.

- Increased Operational Uptime: Minimize blockages and maintenance issues.

Contact our experts today to discuss how KINTEK's specialized equipment can support your specific rotary kiln and thermal processing challenges.

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Three-dimensional electromagnetic sieving instrument

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Large Vertical Graphite Vacuum Graphitization Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What is a roller mixer used for in the laboratory? Achieve Gentle, Aeration-Free Mixing

- What is grinder in chemistry? A Guide to Precision Sample Preparation

- What is the mechanism of action of a colloid mill? Master High-Shear Processing for Superior Emulsions and Dispersions

- What is the difference between mixer and disperser? Choose the Right Tool for Your Process

- What are laboratory mixers used for? Achieve Perfect Sample Homogeneity and Reliable Results