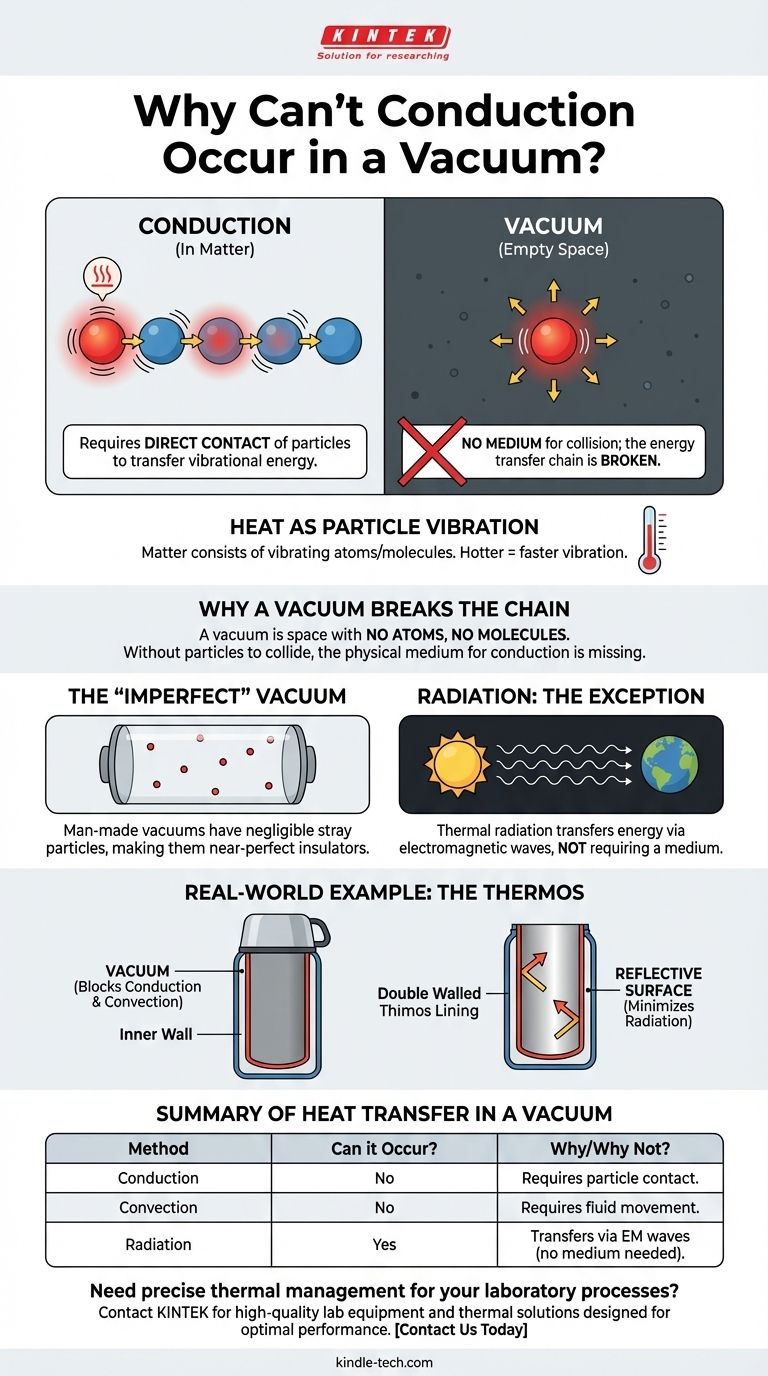

In short, thermal conduction cannot occur in a perfect vacuum because it fundamentally requires particles to transfer energy. A vacuum, by its very definition, is a space devoid of the atoms and molecules that act as the medium for this transfer, breaking the essential chain of energy propagation.

A vacuum acts as a powerful insulator against conduction because this method of heat transfer depends entirely on the collision of neighboring particles. With no particles to collide, the primary pathway for conduction is completely removed.

The Physical Mechanism of Conduction

To understand why a vacuum stops conduction, we must first understand how conduction works at the atomic level.

Heat as Particle Vibration

All matter is composed of atoms and molecules that are in constant motion. The temperature of a material is a measure of the average kinetic energy—or vibrational energy—of these particles. Hotter particles vibrate more vigorously than cooler ones.

The Role of Direct Contact

Conduction is the transfer of this vibrational energy through direct contact. When a fast-vibrating (hot) particle collides with its slower-vibrating (cool) neighbor, it transfers some of its kinetic energy. This process creates a chain reaction, with energy passed from particle to particle, causing heat to flow through the material.

Think of it like a line of billiard balls. Striking the first ball transfers energy down the line through a series of collisions. If you remove a ball from the middle of the line, the chain is broken, and the energy cannot propagate further.

Why a Vacuum Breaks the Chain

A vacuum is the "missing ball" in our analogy, but on a massive scale.

Defining a Vacuum

A perfect vacuum is a space that contains no matter. There are no atoms, no molecules, and no free electrons. It is, quite literally, empty space.

No Medium, No Transfer

Because conduction relies on particle-to-particle collisions, it cannot happen in a vacuum. There is nothing to vibrate and nothing to collide with. The physical medium required for the energy transfer simply does not exist.

Can Heat Cross a Vacuum at All?

While conduction is impossible, it is critical to know that heat can still travel through a vacuum, but only through a different mechanism.

Convection Also Fails

Convection is heat transfer through the bulk movement of fluids (gases or liquids), like hot air rising. Since a vacuum contains no fluid to move, convection is also impossible.

Radiation: The Exception to the Rule

Thermal radiation is the transfer of energy via electromagnetic waves, such as infrared light. Unlike conduction and convection, radiation does not require a medium.

This is how the Sun's energy travels 93 million miles through the vacuum of space to heat the Earth. The heat you feel from a campfire or a hot stove element is also primarily thermal radiation.

Understanding the Practical Limitations

In the real world, the principles face practical nuances that are important to recognize.

The "Imperfect" Vacuum

Creating a perfect vacuum is technologically impossible. All man-made vacuums, from laboratory chambers to the space between the panes of a double-glazed window, contain some stray atoms and molecules.

Minimal Residual Conduction

Because these stray particles exist, a minuscule amount of conduction can technically occur even in a very strong vacuum. However, the effect is so negligible for most practical purposes that a vacuum is considered a near-perfect insulator against conduction.

The Thermos: A Real-World Example

A thermos flask is an excellent illustration of these principles. It features a double-walled construction with a vacuum sealed between the walls.

- The vacuum almost completely eliminates heat transfer by conduction and convection.

- The walls are often coated with a reflective (silver) layer to minimize heat transfer by radiation.

By tackling all three modes of heat transfer, a thermos can keep its contents hot or cold for hours.

Making the Right Choice for Your Goal

Understanding how vacuums affect heat transfer is essential in many fields of science and engineering.

- If your primary focus is maximizing thermal insulation: A vacuum is the most effective barrier against conduction and convection, but you must also account for minimizing thermal radiation with reflective surfaces.

- If your primary focus is understanding heat in space: Remember that while conduction between disconnected objects is impossible, thermal radiation is the dominant and most critical form of heat transfer to manage in spacecraft design.

- If your primary focus is controlling an industrial process: A vacuum's insulating properties are a key secondary effect to manage, whether your goal is preventing contamination (like in sputtering) or achieving specific process temperatures.

Ultimately, recognizing that heat conduction is a story of physical contact makes it clear why a vacuum—the absence of that contact—is its most effective barrier.

Summary Table:

| Heat Transfer Method | Can it Occur in a Vacuum? | Why or Why Not? |

|---|---|---|

| Conduction | No | Requires direct particle-to-particle contact and collisions. A vacuum has no particles to carry the energy. |

| Convection | No | Requires the bulk movement of a fluid (gas or liquid). A vacuum contains no fluid to move. |

| Radiation | Yes | Transfers energy via electromagnetic waves (e.g., infrared light). Does not require any medium. |

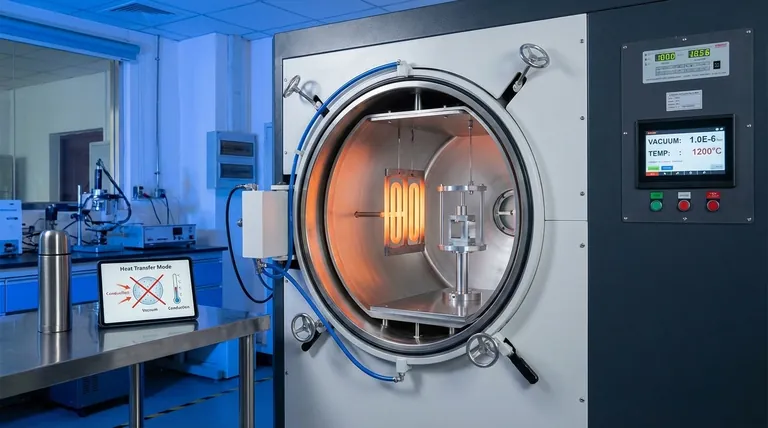

Need precise thermal management for your laboratory processes? Understanding heat transfer is critical for everything from vacuum furnace operation to sample preparation. At KINTEK, we specialize in high-quality lab equipment, including vacuum ovens and thermal processing systems designed for optimal performance and insulation. Let our experts help you select the right tools for your specific application. Contact us today to discuss your laboratory's thermal management needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is sintering in a furnace? A Guide to Creating Strong, Dense Parts from Powder

- What are the factors of pyrolysis? Balancing Technical and Economic Levers for Success

- What are the 4 heat treatments of steel? Master Hardness, Toughness & More

- What are the advantages of using an independent internal charging tank in a vertical vacuum distillation furnace?

- What is the leak rate for a vacuum furnace? Ensure Process Purity and Repeatability

- In what ways can you detect leaks in vacuum system? Master Leak Detection for Optimal Performance

- How is heat transferred in a vacuum furnace? Mastering Radiative Heat for Purity and Precision

- What are the advantages of using a Spark Plasma Sintering (SPS/FAST) system for LLZTO? Rapid Densification & Purity