In thin-film deposition, a vacuum is not just a best practice; it is a fundamental requirement. This controlled, low-pressure environment is essential for creating a pure pathway for deposition material to travel from its source to the substrate. A vacuum eliminates atmospheric gases that would otherwise contaminate the film, interfere with the deposition process, and prevent the formation of a dense, well-adhered layer.

The primary purpose of a vacuum is to remove unwanted particles. This achieves two critical goals: it prevents contamination of the thin film and ensures the depositing atoms travel unimpeded, retaining the energy needed for strong adhesion and a high-quality film structure.

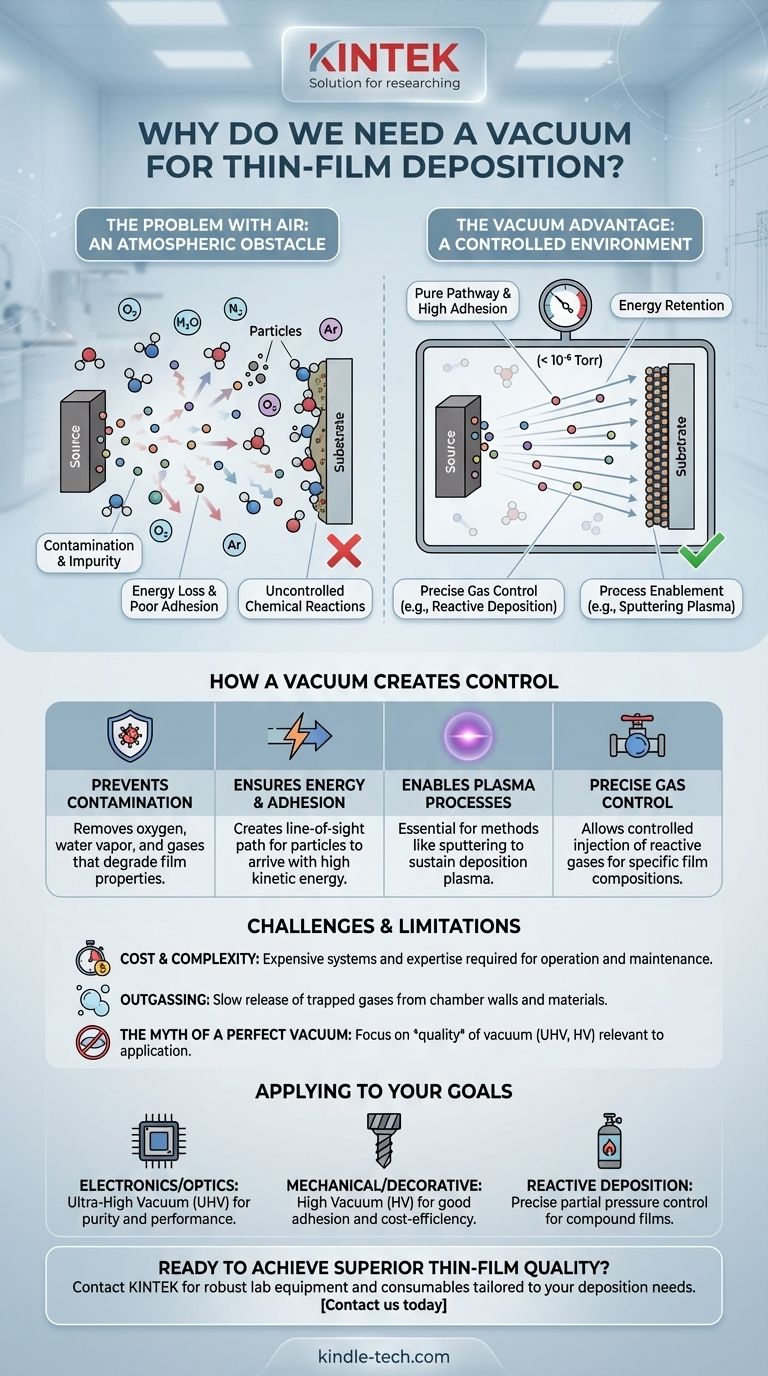

The Problem with Air: Why an Atmosphere Is the Enemy

To understand the need for a vacuum, we must first recognize that standard atmosphere is incredibly hostile to the process of building a high-quality thin film. Air is a dense mixture of reactive gases and particles.

Contamination and Impurity

Air is composed of nitrogen, oxygen, water vapor, argon, and various other trace gases. If these molecules are present during deposition, they will inevitably be incorporated into the film alongside your desired material.

This contamination severely degrades the film's properties. For example, an unwanted oxide layer in a conductive film can ruin its electrical performance, while impurities in an optical coating can cause it to absorb light instead of transmitting it.

Energy Loss and Poor Adhesion

Atoms or molecules traveling from the source to the substrate in a PVD (Physical Vapor Deposition) process need to arrive with sufficient kinetic energy. This energy is critical for forming a strong bond with the substrate surface.

In open air, the traveling particles would collide with billions of air molecules, losing energy with each collision. A vacuum removes these obstacles, creating a "line-of-sight" path. This ensures the particles arrive with maximum energy, promoting better adhesion and a denser film structure.

Uncontrolled Chemical Reactions

Many materials used in thin-film deposition are highly reactive, especially at the high temperatures involved. Oxygen and water vapor in the atmosphere can cause immediate, uncontrolled oxidation of the source material or the film as it forms.

A vacuum removes these reactive agents, giving the process engineer complete control over the chemical environment.

How a Vacuum Creates a Controlled Environment

By removing the chaotic and contaminating influence of air, a vacuum provides the control necessary to engineer a film with specific, repeatable properties.

Enabling the Deposition Process

Certain deposition methods, particularly plasma-based processes like sputtering, simply cannot function at atmospheric pressure. They require a low-pressure environment to ignite and sustain the plasma that is central to the deposition mechanism.

Guaranteeing Repeatability

Atmospheric conditions like pressure and humidity are constantly changing. By operating in a vacuum, you eliminate these variables. This allows engineers to create a consistent, repeatable recipe for a film, ensuring that a part manufactured today has the exact same properties as one manufactured next year.

Precisely Controlling Gas Composition

In some advanced processes, known as reactive deposition, a specific gas is intentionally introduced into the vacuum chamber. For instance, nitrogen might be added while sputtering titanium to create a hard, gold-colored titanium nitride (TiN) coating.

The vacuum system first removes all unwanted air, then allows for the precise injection and partial pressure control of the desired reactive gas. This level of control is impossible without first creating a vacuum.

Understanding the Challenges and Limitations

While essential, creating and maintaining a vacuum introduces its own set of technical challenges that must be managed.

The Myth of a Perfect Vacuum

It is impossible and impractical to create a truly "perfect" vacuum, which would be a space with zero particles. Instead, processes are defined by the quality of the vacuum, such as low, high (HV), or ultra-high vacuum (UHV). The required level depends entirely on the application's sensitivity to contamination.

Cost and Complexity

Vacuum systems, including chambers, pumps, and gauges, are expensive to purchase and require significant expertise to operate and maintain. Achieving and measuring ultra-high vacuums adds substantial cost and complexity to any manufacturing line.

The Problem of Outgassing

Even within a vacuum chamber, contamination can arise from "outgassing." This is the slow release of trapped gases from the chamber walls, fixtures, or even the substrate itself. To combat this, high-vacuum systems are often "baked out" at high temperatures to drive off these trapped molecules before the deposition begins.

Applying This to Your Deposition Goals

The level of vacuum you require is directly tied to the sensitivity and performance demands of your final product.

- If your primary focus is high-purity electronics or optics: An ultra-high vacuum (UHV) is non-negotiable to minimize contamination that would degrade electrical or optical performance.

- If your primary focus is mechanical or decorative coatings: A high vacuum (HV) is often sufficient to ensure good adhesion and prevent major impurities, balancing cost with performance.

- If you are using reactive deposition: The vacuum system is critical not just for removing air, but for precisely controlling the partial pressure of the reactive gas like oxygen or nitrogen.

Ultimately, understanding the role of vacuum shifts your perspective from simply operating equipment to fundamentally controlling the quality and properties of the material you create.

Summary Table:

| Function of Vacuum | Benefit for Thin-Film Deposition |

|---|---|

| Removes Air Molecules | Prevents contamination from gases like oxygen and water vapor |

| Creates Line-of-Sight Path | Ensures particles retain energy for strong adhesion and dense film structure |

| Enables Plasma Processes | Allows methods like sputtering to function by sustaining a plasma |

| Provides Process Control | Eliminates atmospheric variables for repeatable, high-quality results |

| Controls Gas Composition | Enables precise reactive deposition (e.g., adding nitrogen for TiN coatings) |

Ready to achieve superior thin-film quality in your lab? The right vacuum environment is critical for producing high-purity, well-adhered coatings with repeatable results. At KINTEK, we specialize in providing robust lab equipment and consumables tailored to your deposition needs. Whether you're working on sensitive electronics, optical coatings, or durable mechanical layers, our expertise ensures you have the control and purity required for success. Contact us today to discuss how our solutions can enhance your thin-film processes and deliver the performance your research demands.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance