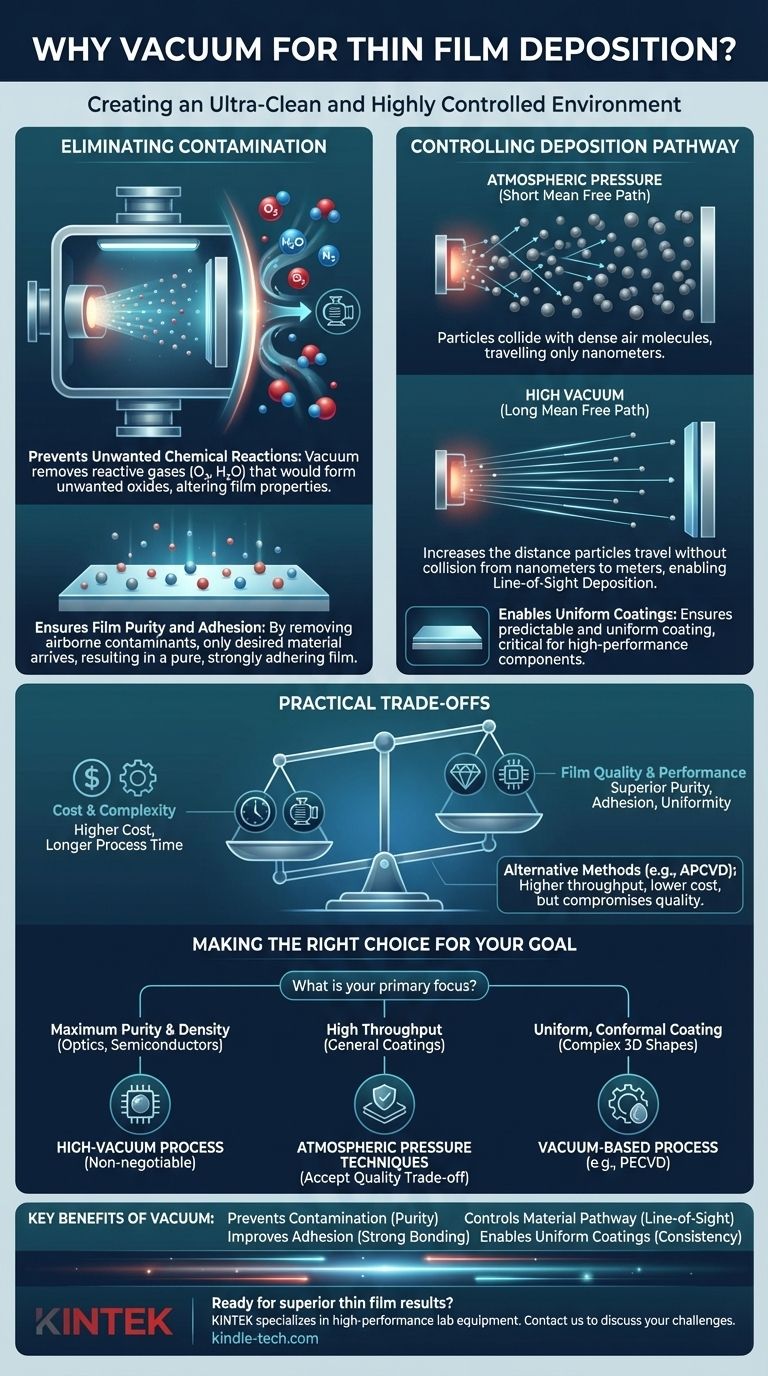

The fundamental reason we use a vacuum for thin film deposition is to create an ultra-clean and highly controlled environment. Removing air and other atmospheric gases prevents the deposition material from reacting with contaminants like oxygen and water vapor, while also allowing the material particles to travel unimpeded from their source to the substrate.

In short, a vacuum is not about creating emptiness for its own sake. It is about removing uncontrolled, reactive variables (the atmosphere) to gain precise control over the purity, structure, and pathway of the material being deposited.

The Primary Role of Vacuum: Eliminating Contamination

Achieving the desired film properties begins with creating a pristine environment. The ordinary air around us is a dense mixture of reactive gases and particles that are detrimental to high-quality thin films.

Preventing Unwanted Chemical Reactions

Atmospheric air is composed primarily of nitrogen and oxygen, with significant amounts of water vapor and other trace gases. These gases are highly reactive.

During deposition, hot or energetic material travels to the substrate. If air were present, this material would instantly react with oxygen and water, forming unwanted oxides or hydroxides instead of the intended pure film.

This chemical contamination fundamentally alters the film's electrical, optical, and mechanical properties, leading to device failure or poor performance.

Ensuring Film Purity and Adhesion

Contamination doesn't just happen mid-flight; it also affects the substrate. As noted in deposition preparation, pre-cleaning removes contaminants from the substrate surface to ensure good adhesion.

A vacuum extends this principle to the entire process volume. By removing airborne contaminants like water molecules and hydrocarbons, the vacuum ensures that only the desired deposition material arrives at the clean substrate, resulting in a pure film that adheres strongly.

Controlling the Deposition Pathway

Beyond purity, a vacuum is essential for physically controlling how the deposition material travels from the source to the target. This is governed by a principle known as the "mean free path."

The Concept of Mean Free Path

Mean free path is the average distance a particle can travel before it collides with another particle.

At normal atmospheric pressure, the mean free path is incredibly short—on the scale of nanometers. Air molecules are packed so densely that a particle cannot travel far without a collision.

Increasing the Mean Free Path

Creating a vacuum drastically reduces the number of gas molecules in the chamber. This increases the mean free path from nanometers to meters.

With fewer air molecules to run into, the atoms or molecules of the deposition material can travel in a straight line directly from the source to the substrate.

Enabling Line-of-Sight Deposition

This long mean free path is the foundation of "line-of-sight" deposition, which is critical for many Physical Vapor Deposition (PVD) techniques like sputtering and evaporation.

It ensures that the material coats the substrate predictably and uniformly, which is essential for creating high-performance optical and electronic components.

The Practical Trade-offs of Using Vacuum

While essential for high-quality films, creating and maintaining a vacuum introduces practical challenges that represent key trade-offs in manufacturing.

Cost and Complexity

Vacuum systems—including chambers, high-power pumps, and sensitive gauges—are expensive to purchase and require specialized knowledge for operation and maintenance. This adds significant capital and operational cost to the deposition process.

Process Time and Throughput

Achieving the necessary level of vacuum is not instantaneous. The "pump-down" time required to evacuate the chamber can be a significant portion of the total process time, potentially limiting manufacturing throughput.

Alternative Deposition Methods

For certain applications where the absolute highest purity or film density is not required, alternative methods that operate at or near atmospheric pressure exist.

Techniques like atmospheric pressure Chemical Vapor Deposition (APCVD) or sol-gel processes can offer higher throughput and lower cost, but typically involve a compromise in the ultimate quality and performance of the film.

Making the Right Choice for Your Goal

The decision to use a vacuum-based process hinges entirely on the required properties of the final thin film.

- If your primary focus is maximum purity and density for optics or semiconductors: A high-vacuum process is non-negotiable to eliminate contaminants and guarantee predictable film growth.

- If your primary focus is high throughput for general protective or aesthetic coatings: You may explore atmospheric pressure techniques, accepting the trade-off in film purity for significantly lower cost and higher speed.

- If your primary focus is a uniform, conformal coating on complex 3D shapes: A vacuum-based process like Plasma-Enhanced Chemical Vapor Deposition (PECVD) is often essential for controlling the gas-phase reactions needed to coat all surfaces evenly.

Ultimately, mastering the vacuum environment is fundamental to controlling the final properties and performance of your thin film.

Summary Table:

| Key Benefit | How Vacuum Helps |

|---|---|

| Prevents Contamination | Removes reactive gases (O₂, H₂O) to ensure film purity. |

| Controls Material Pathway | Increases mean free path for direct, line-of-sight deposition. |

| Improves Adhesion | Creates a clean substrate surface for strong film bonding. |

| Enables Uniform Coatings | Allows precise control for consistent film thickness and properties. |

Ready to achieve superior thin film results in your lab?

KINTEK specializes in high-performance lab equipment, including vacuum deposition systems tailored for research and production. Our expertise ensures you get the purity, adhesion, and uniformity required for advanced optics, semiconductors, and protective coatings.

Contact our experts today to discuss your specific deposition challenges and discover the right vacuum solution for your laboratory needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition