At its core, a high vacuum is required in a deposition chamber for two fundamental reasons: to ensure the purity of the deposited material and to provide a clear, unobstructed path for particles to travel from their source to the substrate. Without a high vacuum, atoms from the air—primarily oxygen, nitrogen, and water vapor—would contaminate the thin film and collide with the deposition particles, scattering them and preventing the formation of a dense, uniform layer.

The primary purpose of a high vacuum is not simply to remove air, but to create a controlled, ultra-clean environment. This ensures that the only atoms reaching the target substrate are the intended deposition materials, allowing for the creation of thin films with precise chemical, electrical, and mechanical properties.

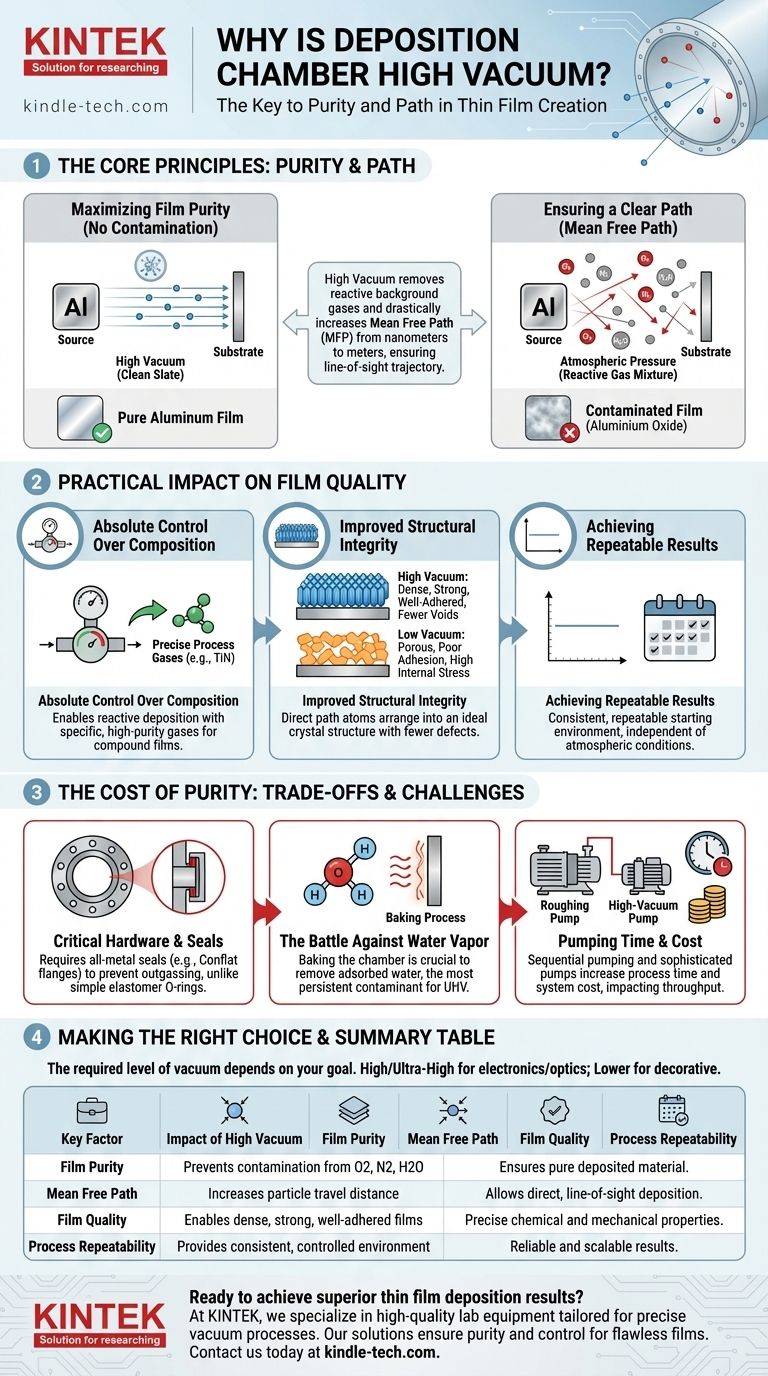

The Core Principles: Purity and Path

Achieving a high-quality thin film is a game of atomic-level control. The environment inside the chamber is the single most important factor determining the outcome, and a high vacuum provides the necessary control over that environment.

Maximizing Film Purity

The air we breathe is a reactive gas mixture. If left in the chamber, these gas molecules would readily react with the high-energy atoms being deposited.

This leads to the unintentional formation of oxides and nitrides within your film, drastically altering its properties. For example, a pure aluminum film for a mirror would become a hazy aluminum oxide film, ruining its reflectivity.

A high vacuum removes these reactive background gases to a level where their influence becomes negligible, ensuring the deposited film is as pure as its source material.

Ensuring a Clear Path (Mean Free Path)

In physics, mean free path (MFP) is the average distance a particle travels before colliding with another particle.

At atmospheric pressure, the MFP is incredibly short—on the scale of nanometers. A deposition atom would collide with billions of air molecules, scattering in random directions long before it could ever reach the substrate.

By creating a high vacuum, we drastically reduce the number of molecules in the chamber, increasing the MFP from nanometers to many meters—far longer than the dimensions of the chamber itself. This guarantees a direct, line-of-sight trajectory from the source to the substrate, which is essential for forming a dense and uniform film.

The Practical Impact on Film Quality

The principles of purity and path have direct, measurable consequences on the final product. Moving from a low vacuum to a high vacuum fundamentally changes the quality and reliability of the deposition process.

Absolute Control Over Composition

A high vacuum creates a clean slate. Once the chamber is evacuated of unwanted gases, you can introduce specific, high-purity process gases in precise amounts.

This is critical for reactive deposition, where a gas like nitrogen or oxygen is intentionally added to form a compound film, such as titanium nitride (TiN). The process only works if the background vacuum is clean enough that the deliberately introduced gas is the primary reactant.

Improved Structural Integrity

Collisions and contamination create defects. Films deposited in a poor vacuum are often porous, poorly adhered to the substrate, and have high internal stress.

In contrast, films grown in a high vacuum are denser, stronger, and adhere much better to the substrate surface. The direct path of the atoms allows them to arrange into a more ideal crystal structure with fewer voids and impurities.

Achieving Repeatable Results

Atmospheric conditions, especially humidity, fluctuate constantly. A process that relies on a low-quality vacuum will produce different results on a dry winter day versus a humid summer day.

A high vacuum system provides a consistent, repeatable starting environment for every single run. This reliability is the foundation of any scalable manufacturing process, from semiconductor fabrication to optical coatings.

Understanding the Trade-offs: The Cost of Purity

Achieving and maintaining a high vacuum is a significant engineering challenge that involves specific hardware and procedures, each with its own costs and benefits.

The Critical Role of Chamber Hardware

Simple elastomer O-rings, common in low-vacuum systems, are unsuitable for high vacuum because they absorb gases (especially water) and slowly release them, a process called outgassing.

This is why high-vacuum systems use all-metal seals, such as Conflat (CF) flanges. These can be heated, or "baked," to high temperatures.

The Battle Against Water Vapor

Baking the chamber provides energy to adsorbed water molecules stuck to the internal surfaces, helping them break free so they can be pumped out. This is a crucial step for reaching ultra-high vacuum (UHV) levels, as water vapor is the most persistent and difficult-to-remove contaminant.

Pumping Time and Cost

Achieving high vacuum is not instant. It typically requires a sequence of pumps—first a "roughing" pump to remove most of the air, followed by a "high-vacuum" pump (like a turbomolecular or cryopump) to remove the remaining molecules.

This process takes time, known as "pump-down time," which directly affects process throughput. The sophisticated pumps and hardware also represent a significant portion of the system's cost. The level of vacuum is therefore a trade-off between the required film quality and the acceptable operational cost and time.

Making the Right Choice for Your Goal

The required level of vacuum is dictated entirely by the desired properties of the final film.

- If your primary focus is high-purity films for electronics or optics: A high or ultra-high vacuum is non-negotiable to prevent contamination and ensure optimal performance.

- If your primary focus is a simple decorative coating where some impurities are tolerable: A lower-grade vacuum may be sufficient, which can reduce equipment cost and cycle time.

- If you are troubleshooting a deposition process with poor film quality: Your first action should be to investigate the vacuum level, checking for leaks or sources of outgassing, as an inadequate vacuum is the most common cause of failure.

Ultimately, the quality of your vacuum environment directly dictates the quality of your deposited film.

Summary Table:

| Key Factor | Impact of High Vacuum |

|---|---|

| Film Purity | Prevents contamination from oxygen, nitrogen, and water vapor, ensuring a pure deposited material. |

| Mean Free Path | Increases particle travel distance, allowing direct, line-of-sight deposition for uniform layers. |

| Film Quality | Enables dense, strong, and well-adhered films with precise chemical and mechanical properties. |

| Process Repeatability | Provides a consistent, controlled environment for reliable and scalable manufacturing results. |

Ready to achieve superior thin film deposition results? At KINTEK, we specialize in high-quality lab equipment and consumables tailored for precise vacuum deposition processes. Our expertise ensures your laboratory operates with the purity and control needed for flawless thin films. Contact us today to discuss how our solutions can enhance your deposition chamber performance and meet your specific laboratory needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition