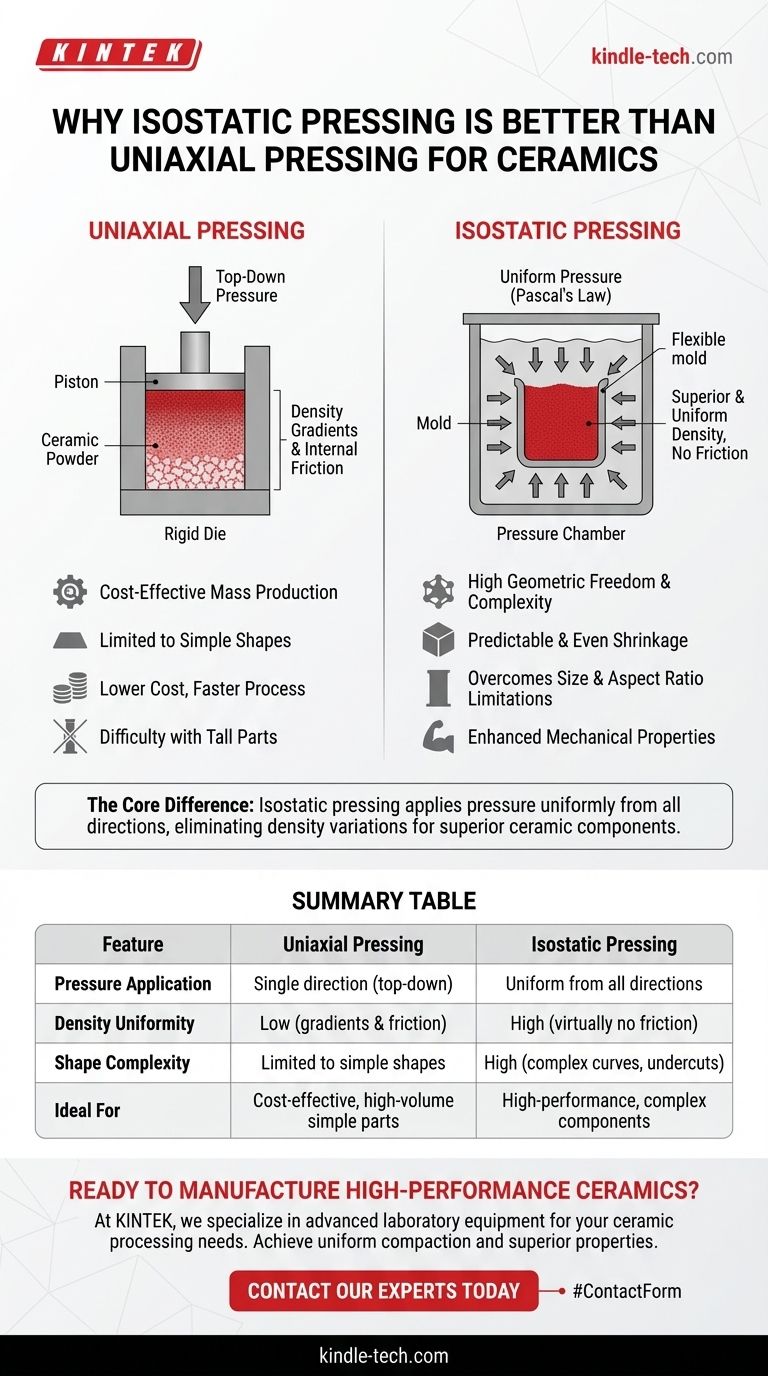

At its core, isostatic pressing is superior to uniaxial pressing because it applies pressure uniformly from all directions, not just one. This fundamental difference eliminates the internal friction and density variations that plague uniaxial methods, resulting in ceramic components with significantly higher, more uniform density and the ability to form far more complex shapes.

While uniaxial pressing is a fast and cost-effective method for simple shapes, isostatic pressing unlocks a higher tier of performance and geometric freedom by ensuring every particle in the ceramic powder is compacted evenly.

The Fundamental Difference: Pressure Application

To understand the benefits, you must first grasp the physical principle separating these two techniques. The method of applying pressure dictates the final quality of the part.

Uniaxial Pressing: A Top-Down Squeeze

Uniaxial pressing acts like a simple piston. Powder is placed in a rigid die, and a punch compresses it from the top down.

This creates significant friction between the powder particles and against the die walls. As a result, the pressure at the top of the part is much higher than at the bottom, leading to density gradients throughout the component.

Isostatic Pressing: A Uniform Squeeze

Isostatic pressing submerges a powder-filled, flexible mold into a high-pressure fluid. In accordance with Pascal's Law, this pressure is transmitted equally and instantly to every point on the component's surface.

This all-around pressure virtually eliminates internal friction, allowing particles to arrange themselves into a much denser and more regular packing structure. The result is a "green" (unsintered) part with exceptionally uniform density.

Key Advantages of Isostatic Pressing

This uniform pressure application directly translates into tangible manufacturing and performance benefits for ceramic components.

Superior Density and Uniformity

Because the green density is uniform, the part shrinks predictably and evenly during the final sintering (firing) stage. This dramatically reduces the risk of warping, cracking, or internal stresses that are common in uniaxially pressed parts due to their density variations.

Geometric Freedom and Complexity

Uniaxial pressing is limited to simple shapes that can be ejected from a rigid die. Isostatic pressing uses a flexible mold, allowing for the creation of parts with complex curves, undercuts, and intricate internal cavities that are impossible to produce otherwise.

Overcoming Size Limitations

In uniaxial pressing, making a tall part (a high height-to-diameter ratio) is extremely difficult. Friction along the die wall prevents pressure from reaching the bottom of the part effectively.

Isostatic pressing completely overcomes this limitation, producing uniformly dense parts regardless of their size or aspect ratio.

Enhanced Material Properties

A higher, more uniform density means fewer internal voids or defects in the final sintered ceramic. This directly leads to improved mechanical properties, such as greater hardness, wear resistance, and thermal stability for high-performance applications.

Understanding the Trade-offs

Isostatic pressing is not universally superior; its advantages come at a cost that makes it unsuitable for certain applications.

Higher Cost

The equipment for isostatic pressing, which involves high-pressure vessels and specialized fluid systems, is significantly more expensive than a standard mechanical press. Tooling, which consists of custom flexible molds, can also be more costly than simple rigid dies.

Increased Process Complexity

Isostatic pressing cycles are typically longer than the rapid stamping action of a uniaxial press. The process of filling, sealing, and handling flexible molds adds steps and complexity, making it less suitable for high-volume production of simple commodity items.

Choosing the Right Pressing Method

The decision to use isostatic or uniaxial pressing is not about which is "better" in a vacuum, but which is best aligned with your specific goal.

- If your primary focus is cost-effective mass production of simple shapes: Uniaxial pressing is the clear choice due to its speed, low cost, and simplicity.

- If your primary focus is maximum performance and geometric complexity: Isostatic pressing is necessary to achieve the uniform density and shape freedom required for critical components.

- If your primary focus is creating large parts with a high aspect ratio: Isostatic pressing is often the only viable method to ensure structural integrity throughout the component.

Ultimately, your choice depends on balancing the engineering requirements of the component against the economic realities of its production.

Summary Table:

| Feature | Uniaxial Pressing | Isostatic Pressing |

|---|---|---|

| Pressure Application | Single direction (top-down) | Uniform from all directions |

| Density Uniformity | Low (gradients and friction) | High (virtually no friction) |

| Shape Complexity | Limited to simple shapes | High (complex curves, undercuts) |

| Ideal For | Cost-effective, high-volume simple parts | High-performance, complex components |

Ready to manufacture high-performance ceramic components with superior density and complex geometries?

At KINTEK, we specialize in providing advanced laboratory equipment, including solutions for your ceramic processing needs. Our expertise helps you achieve the uniform compaction and material properties required for critical applications.

Contact our experts today via our Contact Form to discuss how our solutions can enhance your ceramic manufacturing process.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is cold isostatic pressing? Achieve Uniform Density for Complex Parts

- What is the cold isostatic pressing method? Achieve Uniform Density in Complex Parts

- What is the isostatic pressing method for producing ceramic products? Achieve Uniform, High-Density Ceramic Components

- What is cold isostatic pressing examples? Achieve Uniform Density in Powder Compaction

- What is the significance of the Cold Isostatic Press (CIP)? Optimize Lithium-Filled LLZO Composite Anode Preparation

- What is isostatic pressing of ceramics? Achieve Uniform Density and Complex Shapes

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What are the industrial applications of cold work? Achieve Superior Strength and Precision in Metal Parts