The final sintering temperature is the single most critical parameter that determines the success or failure of the process. It governs the atomic-level changes that transform a loose powder compact into a dense, functional component. The correct temperature creates a strong, precise part, while the wrong temperature can result in a component that is either too porous and weak or one that is melted and distorted.

Sintering is a thermal balancing act. The final temperature must be high enough to drive atomic diffusion and densification but low enough to avoid the destructive effects of excessive grain growth, slumping, or melting. This optimal temperature range, or "sintering window," is unique to each material system.

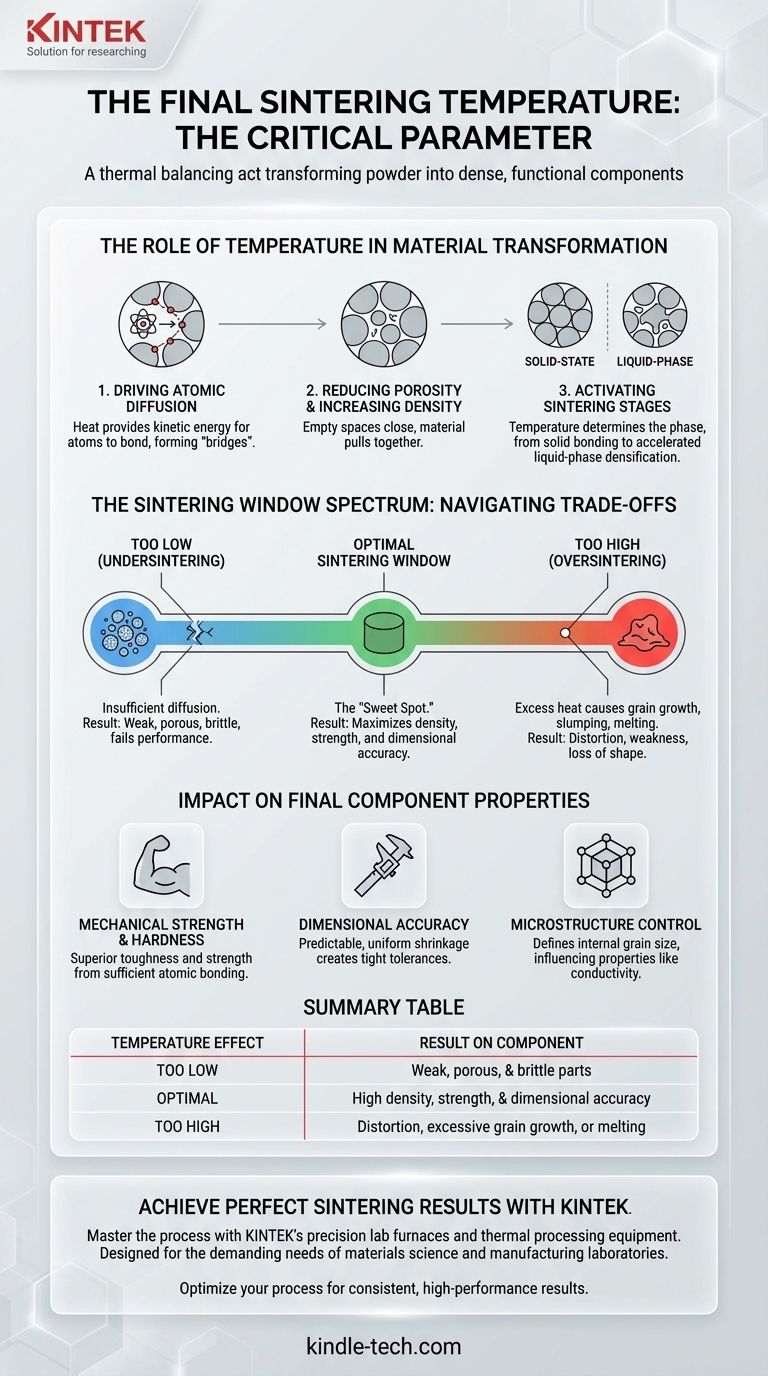

The Role of Temperature in Material Transformation

The primary purpose of heat in sintering is to provide the energy needed to bond individual particles together permanently. This is not a simple melting process but a complex series of temperature-activated mechanisms.

Driving Atomic Diffusion

Heat gives atoms the kinetic energy they need to move. During sintering, atoms migrate across the boundaries of adjacent powder particles, effectively building "bridges" between them. This process, known as atomic diffusion, is what fuses the particles into a solid mass.

Reducing Porosity and Increasing Density

As diffusion occurs, the empty spaces, or pores, between the powder particles begin to shrink and close. The material pulls itself together on a microscopic level. The higher the temperature, the faster this diffusion and densification happen, leading to a stronger final part.

Activating Sintering Stages

For many material systems, temperature determines the phase of the process. At lower temperatures, solid-state sintering occurs, where particles bond without any liquid forming. If the temperature is raised above the eutectic temperature—the lowest temperature at which a liquid can form—the process transitions to liquid-phase sintering. This liquid phase can dramatically accelerate densification.

Understanding the Trade-offs: The Temperature Spectrum

Choosing the final sintering temperature is not about simply picking the highest possible value. It involves navigating a spectrum of risks to find the optimal balance for the desired outcome.

The Risk of Undersintering (Too Low)

If the temperature is too low, atomic diffusion will be insufficient. The bonds between particles will be weak, and a significant amount of porosity will remain. The resulting component will be brittle, lack mechanical strength, and fail to meet performance requirements.

The Risk of Oversintering (Too High)

Exceeding the optimal temperature window is equally problematic. Excess heat can cause rapid and uncontrolled grain growth, where smaller crystal grains merge into larger ones, which can surprisingly make the material weaker or more brittle. In extreme cases, the part can slump under its own weight, lose its precise shape, or even begin to melt.

The "Sintering Window"

Every material has an ideal temperature range known as the sintering window. This is the sweet spot that maximizes density and strength while avoiding the negative effects of undersintering or oversintering. The goal of process development is to precisely identify and control operations within this window.

The Impact on Final Component Properties

The final sintering temperature directly dictates the critical performance characteristics of the manufactured part.

Mechanical Strength and Hardness

A well-sintered part with high density and low porosity will exhibit superior hardness, toughness, and strength. This is a direct result of achieving sufficient atomic bonding, which can only happen at the correct temperature.

Dimensional Accuracy

Many sintered parts are valued for their complex geometries and tight tolerances. Precise temperature control is essential for ensuring the part shrinks predictably and uniformly, maintaining its intended final dimensions without distortion.

Microstructure Control

Temperature doesn't just affect density; it defines the final microstructure, or internal crystal structure, of the material. By controlling the temperature, engineers can control properties like grain size, which in turn influences everything from mechanical strength to electrical conductivity.

Making the Right Choice for Your Goal

Setting the correct temperature depends entirely on the material being used and the performance you need to achieve.

- If your primary focus is maximum density and strength: You will need to operate at the higher end of the material's sintering window, just below the temperature that causes excessive grain growth or distortion.

- If your primary focus is preserving a fine-grained microstructure for specific properties: You may use a slightly lower temperature for a longer duration or employ advanced techniques to achieve densification without grain coarsening.

- If your primary focus is dimensional precision for a complex shape: Your process must prioritize uniform heating and holding the temperature in the middle of the sintering window to ensure predictable shrinkage.

Ultimately, mastering the final sintering temperature is mastering control over the final component's performance, reliability, and quality.

Summary Table:

| Temperature Effect | Result on Component |

|---|---|

| Too Low (Undersintering) | Weak, porous, and brittle parts |

| Optimal (Sintering Window) | High density, strength, and dimensional accuracy |

| Too High (Oversintering) | Distortion, excessive grain growth, or melting |

Achieve Perfect Sintering Results with KINTEK

Mastering the final sintering temperature is essential for producing high-quality, reliable components. Whether your goal is maximum density, precise dimensional control, or specific microstructural properties, the right lab equipment is fundamental to your success.

KINTEK specializes in precision lab furnaces and thermal processing equipment, helping you accurately control the sintering process. Our solutions are designed to meet the demanding needs of materials science and manufacturing laboratories.

Ready to optimize your sintering process and ensure consistent, high-performance results?

Contact our thermal processing experts today to discuss your specific application and discover how KINTEK's equipment can enhance your lab's capabilities.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.