In Physical Vapor Deposition (PVD), a vacuum is essential because it clears the path for coating particles to travel and prevents contamination. By removing virtually all air and other gases from a chamber, the vacuum ensures the vaporized coating material can move from its source to the target substrate without colliding with other atoms, resulting in a pure, dense, and high-quality thin film.

The core purpose of the vacuum is to transform the deposition chamber from a chaotic, crowded environment into a controlled highway. It ensures the coating material arrives at its destination cleanly and without interference, which is the fundamental requirement for building a high-performance film, atom by atom.

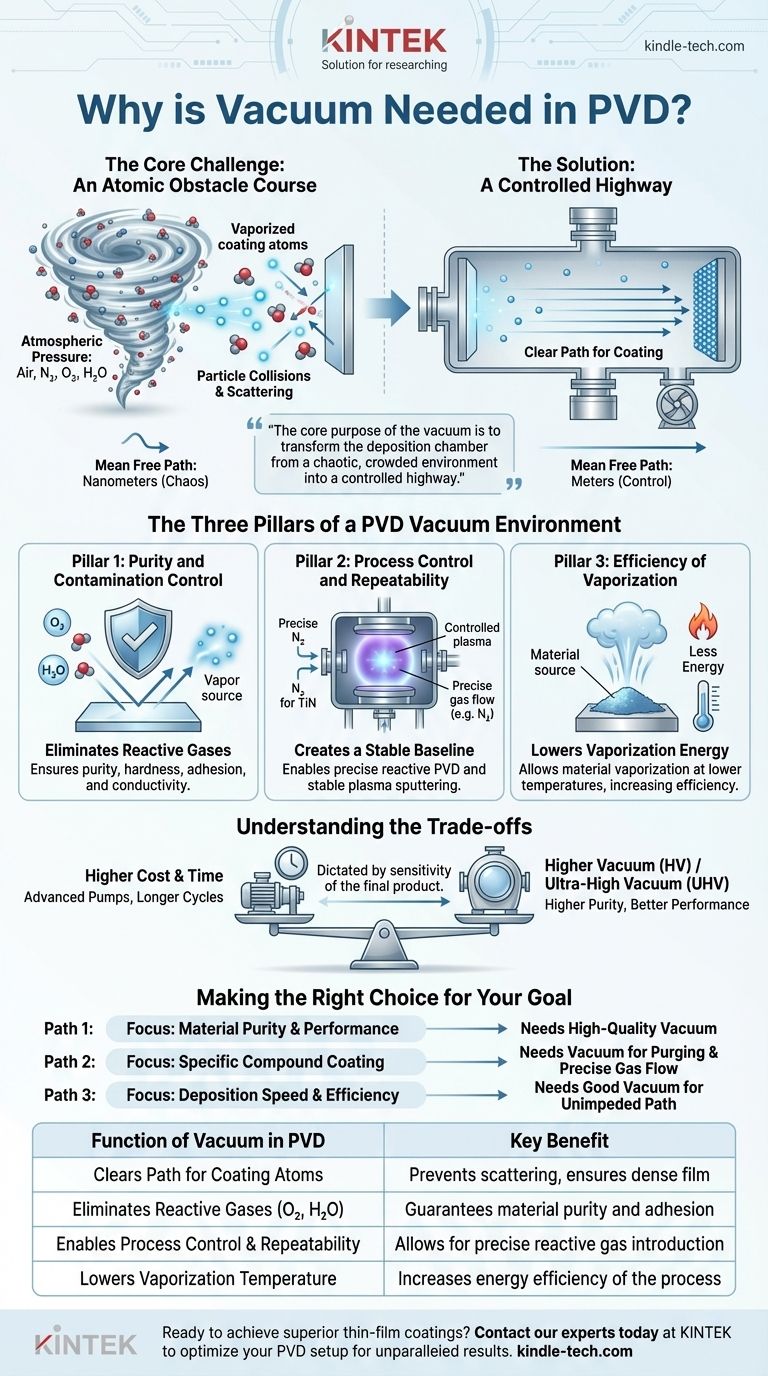

The Core Challenge: An Atomic Obstacle Course

At normal atmospheric pressure, the air around us is incredibly dense with molecules like nitrogen, oxygen, and water vapor. Attempting to perform PVD in these conditions would be like trying to throw a handful of sand through a hurricane.

The Problem of Particle Collisions

The atoms of vaporized coating material are incredibly small. If they are ejected into a chamber filled with air, they will immediately collide with billions of other gas molecules. These collisions would scatter the coating atoms, slow them down, and prevent them from ever reaching the substrate in a straight line.

Understanding the "Mean Free Path"

In physics, the mean free path is the average distance a particle can travel before it collides with another particle. In the dense environment of atmospheric pressure, this distance is measured in nanometers—a path far too short for effective coating.

How Vacuum Creates a Clear Path

Creating a vacuum involves pumping out the air and other gases, which drastically reduces the number of particles in the chamber. This increases the mean free path from nanometers to meters. The vaporized coating atoms now have a clear, unobstructed line of sight to travel from the source to the substrate.

The Three Pillars of a PVD Vacuum Environment

The vacuum does more than just clear a path; it provides the fundamental conditions necessary for control, purity, and efficiency.

Pillar 1: Purity and Contamination Control

Air contains reactive gases, primarily oxygen and water vapor. If left in the chamber, these gases would react with the hot, vaporized coating material and the clean substrate surface. This creates unwanted oxides and other compounds, contaminating the final film and compromising its properties, such as hardness, adhesion, or conductivity.

Pillar 2: Process Control and Repeatability

A vacuum creates a clean, stable, and predictable baseline. It removes all unknown variables, allowing engineers to have total control over the atmosphere. If a specific chemical reaction is desired, such as in reactive PVD, a precise amount of a reactive gas (like nitrogen to create a titanium nitride coating) can be intentionally introduced into the pure vacuum environment.

This low-pressure environment is also critical for processes like sputtering, where a stable plasma must be generated and sustained to bombard the source material.

Pillar 3: Efficiency of Vaporization

Removing the pressure of the surrounding air also makes it easier for the source material to turn into a vapor. This is similar to how water boils at a lower temperature at high altitudes where air pressure is lower. This allows the material to be vaporized at a lower temperature or with less energy, making the entire PVD process more efficient.

Understanding the Trade-offs

Not all vacuum environments are created equal, and achieving the "perfect" vacuum comes with costs.

The Levels of Vacuum

Engineers talk about different levels of vacuum, such as high vacuum (HV) or ultra-high vacuum (UHV). These terms simply refer to how low the pressure is inside the chamber—UHV has far fewer residual gas particles than HV.

The Cost of Purity

Achieving a lower pressure (a better vacuum) requires more advanced, expensive pumping systems and significantly longer pump-down times. This increases both the capital cost of the equipment and the time it takes to process each batch, which affects throughput.

Matching the Vacuum to the Application

The required vacuum level is dictated by the sensitivity of the final product. A simple decorative chrome coating on a plastic part may not require the same extreme level of purity as a complex optical filter or a semiconductor device, where even a few stray atoms of oxygen can cause a component to fail.

Making the Right Choice for Your Goal

The level and quality of the vacuum are directly tied to the desired outcome of the coating.

- If your primary focus is material purity and performance: You need a high-quality vacuum to minimize contamination from reactive gases that degrade the film's properties.

- If your primary focus is creating a specific compound coating (e.g., TiN): The vacuum is crucial for purging all unwanted gases before you introduce a precise flow of a reactive gas.

- If your primary focus is deposition speed and efficiency: A good vacuum ensures a direct, unimpeded path for the vapor stream, maximizing the amount of material that successfully deposits on the substrate.

Ultimately, the vacuum in PVD is the critical element that transforms a chaotic environment into a precisely controlled process for engineering materials at the atomic level.

Summary Table:

| Function of Vacuum in PVD | Key Benefit |

|---|---|

| Clears Path for Coating Atoms | Prevents scattering, ensures dense film |

| Eliminates Reactive Gases (O₂, H₂O) | Guarantees material purity and adhesion |

| Enables Process Control & Repeatability | Allows for precise reactive gas introduction |

| Lowers Vaporization Temperature | Increases energy efficiency of the process |

Ready to achieve superior thin-film coatings? The quality of your PVD process starts with the right vacuum environment and equipment. At KINTEK, we specialize in high-performance lab equipment and consumables tailored for precise PVD applications. Our expertise ensures you get the purity, control, and repeatability needed for cutting-edge research and production. Contact our experts today to discuss how we can optimize your PVD setup for unparalleled results.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

People Also Ask

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition