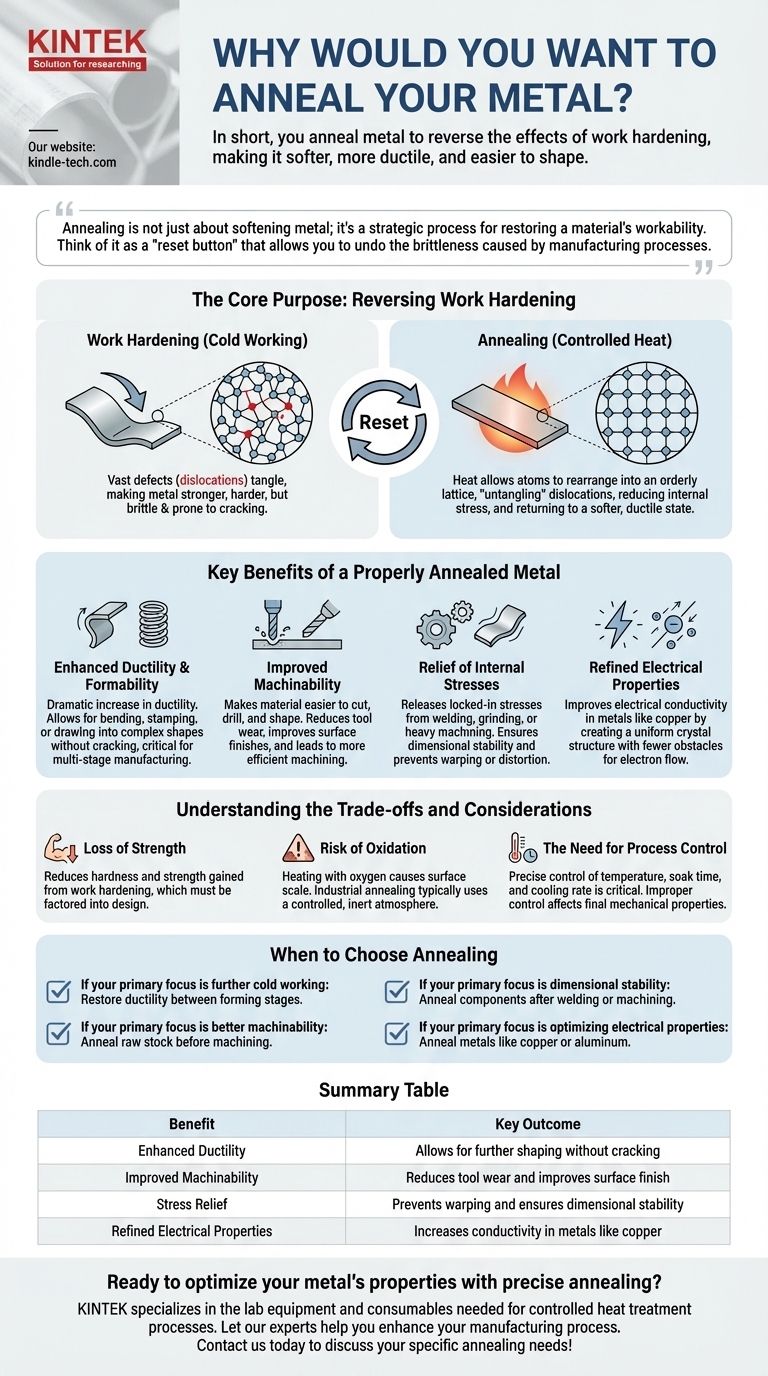

In short, you anneal metal to reverse the effects of work hardening. This heat treatment process makes a material softer, more ductile, and easier to shape. It works by relieving internal stresses and refining the metal's internal crystal structure, which reduces its hardness and makes it significantly less brittle.

Annealing is not just about softening metal; it's a strategic process for restoring a material's workability. Think of it as a "reset button" that allows you to undo the brittleness caused by manufacturing processes, enabling further work or preparing the metal for its final application.

The Core Purpose: Reversing Work Hardening

To understand annealing, you must first understand the problem it solves: work hardening.

What is Work Hardening?

When you bend, hammer, roll, or otherwise deform a metal at room temperature (a process called "cold working"), you are creating a vast number of defects, or dislocations, in its internal crystal structure.

These dislocations get tangled and impede each other's movement. This makes the metal stronger and harder, but it also makes it more brittle and prone to cracking under further stress.

How Annealing Acts as a "Reset"

Annealing applies controlled heat to the metal, allowing its atoms to vibrate and rearrange themselves into a more orderly, low-defect crystal lattice.

This process, known as recrystallization, effectively "untangles" the dislocations. The result is a reduction in internal stress and a return to a softer, more ductile state.

Key Benefits of a Properly Annealed Metal

By resetting the metal's microstructure, annealing provides several distinct advantages for manufacturing and performance.

Enhanced Ductility and Formability

The primary benefit is a dramatic increase in ductility, which is the ability to deform without fracturing. An annealed metal can be bent, stamped, or drawn into complex shapes without cracking.

This is critical in multi-stage manufacturing, where annealing is performed between cold working steps to allow for additional forming.

Improved Machinability

Hard, brittle metals are difficult to machine. They cause excessive wear on cutting tools, can lead to poor surface finishes, and may chip unpredictably.

By reducing hardness, annealing makes the material easier to cut, drill, and shape, leading to a more efficient and precise machining process.

Relief of Internal Stresses

Processes like welding, grinding, and heavy machining can introduce significant internal stresses into a part. These locked-in stresses can cause the part to warp or distort over time, or even crack during subsequent heat treatments.

Annealing provides a controlled way to release these stresses, ensuring the dimensional stability of the finished component.

Refined Electrical Properties

For some metals, particularly copper, the uniform crystal structure created by annealing improves electrical conductivity. A more orderly lattice presents fewer obstacles to the flow of electrons.

Understanding the Trade-offs and Considerations

Annealing is a powerful tool, but it involves critical trade-offs and requires careful process control.

The Obvious Trade-off: Loss of Strength

The entire point of annealing is to reduce hardness and increase ductility. This means you will lose the strength and hardness gained from work hardening. This must be factored into the design and manufacturing sequence.

The Risk of Oxidation

Heating metal in the presence of oxygen will cause a layer of oxide, or scale, to form on its surface. This is often undesirable.

To prevent this, industrial annealing is typically performed in a controlled, inert atmosphere, often using nitrogen or other specialized gas mixtures.

The Need for Process Control

Annealing is not simply a matter of heating metal. The temperature, soak time, and cooling rate are all critical parameters that must be precisely controlled for the specific alloy.

Improper control can lead to incomplete annealing or undesirable grain growth, which can negatively impact the final mechanical properties of the material.

When to Choose Annealing

Applying this knowledge depends entirely on your specific manufacturing goal.

- If your primary focus is further cold working: Use annealing to restore ductility between forming stages, which prevents the material from cracking as you continue to shape it.

- If your primary focus is better machinability: Anneal raw stock before machining to reduce tool wear, increase cutting speeds, and achieve a superior surface finish.

- If your primary focus is dimensional stability: Anneal components after welding or aggressive machining to relieve internal stresses and prevent warping in the final product.

- If your primary focus is optimizing electrical properties: Anneal metals like copper or aluminum to refine the grain structure, thereby maximizing their conductivity.

Ultimately, annealing is a fundamental tool that gives you precise control over a metal's mechanical and physical properties.

Summary Table:

| Benefit | Key Outcome |

|---|---|

| Enhanced Ductility | Allows for further shaping without cracking |

| Improved Machinability | Reduces tool wear and improves surface finish |

| Stress Relief | Prevents warping and ensures dimensional stability |

| Refined Electrical Properties | Increases conductivity in metals like copper |

Ready to optimize your metal's properties with precise annealing?

KINTEK specializes in the lab equipment and consumables needed for controlled heat treatment processes. Whether you're working with raw stock or complex components, our solutions help you achieve the perfect balance of ductility, strength, and stability.

Let our experts help you enhance your manufacturing process. Contact us today to discuss your specific annealing needs!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

People Also Ask

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints

- What are the advantages of brazing compared to welding? Achieve Clean, Low-Distortion Metal Joining

- What is the process of a vacuum furnace? Achieve Purity and Precision in High-Temp Processing

- What are some applications of brazing? Join Dissimilar Metals with Strong, Leak-Proof Bonds

- What is vacuum brazing? The Ultimate Guide to High-Purity, Flux-Free Metal Joining