Identifying Key Factors for Lab Press Selection

Table of Contents

- Identifying Key Factors for Lab Press Selection

- Evaluating the load or force required for the sample

- Assessing the space needed inside the sample compartment

- Understanding the daylight opening and platen size

- Calculating the strength or energy required to pump the press

- Consideration of control over the rate of ramp up or down

- Evaluating the space available in the lab for the press

- Assessing the requirement for press mobility

- Analyzing the cost and optional features

- Hydraulic Press: Do You Really Need It?

- Steps for Making KBr Pellets

- Heating the anvils and the body of the die set

- Using dry KBr powder

- Ensuring the temperature consistency of the anvils, die set, and powder

- Maintaining the dryness of KBr powder

- Limiting the use of KBr powder

- Understanding the importance of grinding the sample, not the KBr powder

- Ensuring the proper assembly and condition of the vacuum die set

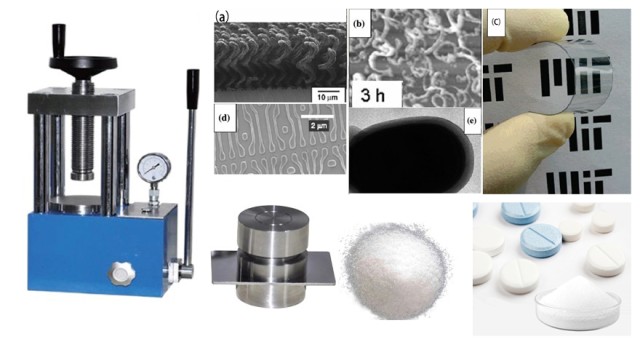

- Applications of Lab Presses

Evaluating the load or force required for the sample

When choosing a lab press, it is important to consider the load or force that will be applied to the sample. This will ensure that the press is capable of providing the necessary pressure for your specific application.

Assessing the space needed inside the sample compartment

The size of the sample compartment is another crucial factor to consider. You need to ensure that the lab press has enough space to accommodate your samples comfortably.

Understanding the daylight opening and platen size

The daylight opening refers to the distance between the platens when the press is fully open. It is important to consider the daylight opening and platen size to ensure that your samples can fit properly and that you have enough space to work with.

Calculating the strength or energy required to pump the press

The strength or energy required to pump the press is another important consideration. You need to ensure that the press has enough power to generate the necessary force for your application.

Consideration of control over the rate of ramp up or down

Some applications require precise control over the rate of ramp up or down. It is important to consider whether the lab press provides this control to ensure accurate and consistent results.

Evaluating the space available in the lab for the press

Before purchasing a lab press, it is important to assess the available space in your lab. This will help you determine the size and type of press that will fit comfortably in your workspace.

Assessing the requirement for press mobility

Depending on your specific needs, you may require a lab press that is mobile. Consider whether you need a press that can be easily moved around or if a stationary press will suffice.

Analyzing the cost and optional features

Cost is always a factor to consider when purchasing lab equipment. Evaluate the cost of the lab press and any optional features that may be beneficial for your application. Consider your budget and the value that these features will add.

Lab presses play a crucial role in preparing samples with reproducible characteristics. It is important to choose the right lab press for your application to ensure consistent and reliable results.

Do I Really Need A Hydraulic Press?

If you are doing briquetting for XRF, the answer is yes–there is no alternative. If you are doing KBr pellets, you should first consider a hand press. The ground sample is pressed by a tablet press into a sample that conforms to the analysis.

Lab tablet presses are available in automatic and manual options. Manual presses are time-consuming and labor-intensive, while automatic presses offer the advantage of preset pressure and holding time, saving effort and ensuring consistent sample conditions.

When choosing a lab press, it is essential to consider the maximum working pressure and the press die. The press's maximum pressure should generally be no less than 30 tonnes to allow for a margin. Press sample molds are available in various materials, including plastic rings, boric acid, low-pressure polyethylene powder, and steel rings.

Selecting the right hydraulic press is crucial for lab managers and researchers. Each application has unique requirements for clamping force, dwelling time, temperature, and other factors. Choosing the right press ensures the creation of successful samples and optimal results.

Laboratory platen presses offer quick and easy adjustment of settings and the ability to switch between different sample types and materials. They have a small footprint, making them convenient for lab use and providing reliable and consistent results over time.

When purchasing a lab press, consider factors such as the required pressure, temperature range, platen size, the importance of computer control, the duration of temperature holding, and whether a benchtop or floor press is suitable for your application and space.

Lab presses are essential for forming samples, pellets, and test specimens in various industries and material categories. They use a combination of pressure and heat to melt powdered material and compress it into the desired shape and size. Lab presses can generate compressive forces ranging from 15 to over 100 tons and have heated platens with temperature ranges from 600°F to 1200°F.

Hydraulic Press: Do You Really Need It?

Understanding the importance of hydraulic press in XRF briquetting

Hydraulic presses are industrial machines that utilize fluid power to generate a compressive force for pressing, forging, and stamping various materials. They play a crucial role in many industrial processes, including metalworking, plastics processing, and woodworking. Hydraulic presses are versatile and efficient, able to perform operations such as forging, punching, blanking, deep drawing, and forming. They come in different sizes, capacities, and configurations to meet specific application requirements.

Considering a hand press for KBr pellets

If you are working with KBr pellets, a hand press can be a suitable option. Hand presses are portable, require minimal lab space, and are relatively easy to operate. They can produce excellent transparent KBr pellets with minimal effort. However, it's important to note that hand-operated presses have drawbacks. They are not ideal for creating samples that can be stored for future reference, and they may not be evacuable or achieve the same efficiency as a hydraulic press in terms of evacuation. If you need to produce a large number of KBr pellets that must be very dry or stored in large quantities, a hydraulic press is necessary.

Recognizing the drawbacks of hand-operated presses

While hand presses are convenient for certain applications, they have limitations. The major drawbacks of hand-operated presses are their inability to create long-term storage samples and their limitations in terms of evacuability. Hand presses are not designed for creating samples that can be stored for future reference. Additionally, they may not achieve the same efficiency in evacuation as a die set designed for a hydraulic press. Therefore, if you require a large number of KBr pellets that need to be very dry or stored in large quantities, a hydraulic press is essential.

Identifying the need for a hydraulic press in large-scale KBr pellet production

For large-scale KBr pellet production, a hydraulic press becomes necessary. Hand presses may not be sufficient for producing a significant number of KBr pellets that need to be very dry or stored in large quantities. Hydraulic presses offer the capability to create samples that can be stored for future reference and achieve efficient evacuation. If you have a high volume of KBr pellet production and need to ensure dryness and storage capability, investing in a hydraulic press is crucial.

Conclusion

Choosing the right press for your laboratory application depends on various factors, including the load or force required, the size of the sample compartment, the platens' size, and the cost of the press and optional features. While hand presses can be suitable for certain applications, hydraulic presses offer more versatility and efficiency. Whether manual or automatic, hydraulic presses provide accurate and repeatable results for various laboratory processes. Consider your specific requirements and consult with experts to find the ideal hydraulic press for your needs.

Steps for Making KBr Pellets

Heating the anvils and the body of the die set

Before making KBr pellets, it is important to heat the anvils and the body of the die set. This helps to ensure that they are as dry as possible, which is crucial for the pellet-making process.

Using dry KBr powder

To make high-quality KBr pellets, it is essential to use dry KBr powder. Moisture can negatively impact the quality of the pellets and affect the FTIR measurement. Therefore, it is important to store the KBr powder in a dry environment, such as a heated case or desiccator, to keep it dry.

Ensuring the temperature consistency of the anvils, die set, and powder

To achieve optimal results, it is crucial to make sure that the anvils, die set, and KBr powder are all at the same temperature. If the powder is hot and the anvils are cold, it can result in the formation of cloudy and wet pellets. Maintaining temperature consistency is key to producing high-quality KBr pellets.

Maintaining the dryness of KBr powder

KBr is hygroscopic, meaning it starts to absorb moisture from the air as soon as the bottle is opened. In humid environments or when samples will have prolonged exposure to air, it is recommended to perform grinding and pressing in a glovebox or with a vacuum die. Storing the KBr powder in a dry and controlled environment helps maintain its dryness.

Limiting the use of KBr powder

Using too much KBr powder is a common mistake when making KBr pellets. It is advisable to use as little KBr powder as possible, only enough to coat the anvils of the die set. Compressing an excessive amount of powder requires more force and can lead to wedging or the formation of white spots on the pellets. Using the proper amount of powder ensures optimal pellet quality.

Understanding the importance of grinding the sample, not the KBr powder

When preparing KBr pellets, it is crucial to focus on grinding the sample, not the KBr powder. Grinding the KBr powder can open crystal facets, which can absorb moisture and affect the quality of the pellets. Instead, mix the sample into the KBr powder without excessive grinding.

Ensuring the proper assembly and condition of the vacuum die set

If vacuum pressing is required, it is important to ensure that the vacuum die set is properly assembled and that the seals are in good condition. This helps to maintain the vacuum and prevent any leaks during the pellet-making process. Detailed pellet-making instructions specific to different accessories are available with specialized presses and dies.

By following these steps, you can easily make high-quality KBr pellets for your FTIR analyses. Remember to maintain temperature consistency, keep the KBr powder dry, and focus on grinding the sample rather than the KBr powder for optimal results.

Applications of Lab Presses

Creating sample pellets for infrared spectroscopy

Lab presses are commonly used to create sample pellets for infrared spectroscopy. This technique involves mixing the sample with potassium bromide (KBr) and compressing it into pellets. These pellets are then used for infrared spectroscopic analysis. By using a hydraulic press, the sample is compressed within a durable container, resulting in consistent and precise pellets for analysis.

Briquetting inorganic samples for XRF spectroscopy

Inorganic samples can be briquetted using lab presses for X-ray fluorescence (XRF) spectroscopy. This process involves compressing the inorganic sample into a briquette shape using a hydraulic press. The briquettes are then analyzed using XRF spectroscopy to determine the elemental composition of the sample. Lab presses provide the necessary pressure to create uniform and standardized briquettes for accurate analysis.

Pressing thin polymer films for transmission sampling by IR spectroscopy

Lab presses are also used to press thin polymer films for transmission sampling by IR spectroscopy. This technique involves placing a thin polymer film between heated platens and applying pressure using a lab press. The pressure and heat help to create a uniform and smooth film for analysis. By using lab presses, researchers can ensure consistent and reliable results in their IR spectroscopy experiments.

Other applications such as pill making and laminating

Lab presses have a wide range of applications beyond spectroscopy. They can be used for pill making, allowing pharmaceutical companies to efficiently produce tablets and wafers for various purposes. Lab presses are also used in laminating processes, where materials such as rubber, plastic, and laminate materials are compacted and bonded together. These presses provide the necessary pressure and precision for the production of high-quality laminated products.

In conclusion, lab presses have diverse applications in various industries and research fields. They are essential tools for creating sample pellets, briquetting inorganic samples, pressing thin polymer films, and other processes such as pill making and laminating. Lab presses offer precise and consistent results, making them invaluable assets in scientific research and industrial applications.

If you are interested in our products, please visit our company website:https://kindle-tech.com/product-categories/heated-lab-press, where innovation has always been a priority. Our R&D team consists of experienced engineers and scientists who closely follow industry trends and are constantly pushing the boundaries of what is possible. Our laboratory equipment incorporates the latest technology to ensure that you can obtain accurate and repeatable results during your experiments. From high-precision instruments to intelligent control systems, our products will provide you with unlimited possibilities for your experimental work.

Related Products

- Laboratory Hydraulic Pellet Press for XRF KBR FTIR Lab Applications

- kbr pellet press 2t

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual Lab Heat Press

Related Articles

- Understanding Hydraulic Pellet Press: Working Mechanism and Applications

- Understanding the Functioning and Applications of a Hydraulic Pellet Press

- Manual Hydraulic Pellet Press: An Efficient Tool for Spectral Analyses Preparation

- A Comprehensive Guide on Pressing XRF Pellets Using a KinTek Automatic Hydraulic Press

- The Benchtop KBr Pellet Press: An Efficient Tool for Laboratory Use