High Technological Threshold

Interdisciplinary Knowledge Integration

PECVD technology is a complex field that necessitates a profound grasp of multiple scientific disciplines. The integration of polymer materials science, plasma physics, chemical vapor deposition, and mechanical manufacturing forms a formidable barrier to entry for most enterprises. Each of these disciplines requires specialized knowledge and expertise, making it challenging for companies to develop a comprehensive understanding that spans all areas.

For instance, polymer materials science is crucial for understanding how different materials interact with the plasma environment, while plasma physics is essential for controlling the plasma's behavior during the deposition process. Chemical vapor deposition techniques dictate the quality and properties of the resulting coatings, and mechanical manufacturing expertise ensures that the equipment used is both efficient and reliable.

This interdisciplinary requirement not only increases the complexity of developing PECVD technology but also raises the cost and time investment needed for research and development. As a result, only a few enterprises with extensive resources and a broad base of knowledge can effectively navigate this intricate landscape.

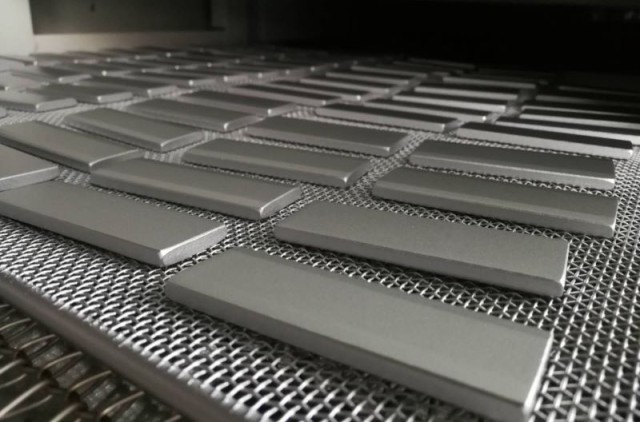

Equipment Independent Research and Development

High Performance Equipment Requirement

The performance of PECVD (Plasma-Enhanced Chemical Vapor Deposition) equipment is a critical determinant of the quality and efficiency of the coatings it produces. This technology, which involves the use of plasma to enhance the chemical vapor deposition process, requires a high level of precision and control. The equipment must be capable of maintaining stable plasma conditions, ensuring uniform deposition across the substrate, and operating at the optimal process parameters to achieve the desired coating properties.

To meet these stringent demands, strong independent R&D capabilities are essential. Developing and refining PECVD equipment involves a multidisciplinary approach, integrating knowledge from fields such as plasma physics, materials science, and chemical engineering. This complexity necessitates a deep understanding of the underlying scientific principles and the ability to translate theoretical knowledge into practical, reliable equipment.

Moreover, the continuous evolution of materials and applications in industries such as semiconductors, optics, and renewable energy requires PECVD equipment to be adaptable and upgradable. This means that manufacturers must invest in ongoing research and development to keep pace with technological advancements and market needs. The ability to innovate and improve equipment performance independently is thus not just a competitive advantage but a necessity for staying relevant in a rapidly evolving field.

Material Formula and Preparation Process Confidentiality

Protecting Intellectual Property

The core material formulations and preparation processes in PECVD nano-coating technology are not just proprietary; they are the lifeblood of competitive advantage in the market. These formulations and processes are meticulously guarded secrets, often protected through a combination of legal measures, including patents, trade secrets, and non-disclosure agreements. The confidentiality of these elements is crucial as they directly influence the quality, efficiency, and uniqueness of the coatings produced.

To maintain this secrecy, companies employ advanced security protocols, both digital and physical, to safeguard their intellectual assets. These measures include restricted access to research and development facilities, encrypted digital storage, and stringent employee vetting processes. The rationale behind such stringent protection is clear: a single leak could compromise years of research and development, leading to a significant loss of market share and competitive edge.

Moreover, the protection of intellectual property extends beyond internal security measures. It involves active engagement with legal frameworks to ensure that any potential breaches are swiftly addressed. This includes monitoring the market for unauthorized use of proprietary technologies and taking legal action when necessary. By doing so, companies not only protect their current investments but also deter future infringements, thereby sustaining their technical and market leadership.

Customized Services and Process Optimization

Meeting Diverse Customer Needs

Customized services in the realm of PECVD nano-coating technology necessitate a meticulous orchestration of numerous variables. This intricate process demands not only high professional abilities but also exceptional organizational efficiency. Each customer's unique requirements can vary significantly, from the specific material compositions to the desired coating properties and application methods. Consequently, the ability to adapt and respond swiftly to these diverse needs is paramount.

To achieve this, a comprehensive understanding of both the technical aspects and the operational dynamics is essential. Technicians must possess a deep knowledge of polymer materials science, plasma physics, and chemical vapor deposition, among other disciplines. Additionally, the organizational structure must be agile and efficient, capable of managing complex workflows and ensuring seamless coordination between various departments.

The challenge lies in the balance between customization and standardization. While each customer's needs are unique, there are underlying patterns and best practices that can be leveraged to streamline the process. This requires continuous innovation and optimization, as well as a commitment to staying ahead of industry trends and technological advancements.

In summary, meeting diverse customer needs in the PECVD nano-coating technology sector is a multifaceted challenge that demands both technical expertise and organizational excellence. The ability to navigate this landscape effectively can be a significant differentiator, setting companies apart in a competitive market.

Industry Expansion and Standardization

Challenges in Emerging Fields

Expanding into new fields such as new energy and biomedicine presents a unique set of challenges that go beyond the traditional boundaries of PECVD nano-coating technology. These emerging fields demand not only a higher level of technical sophistication but also a robust understanding of regulatory frameworks and compliance standards.

Technical Sophistication

In the realm of new energy, for instance, the need for advanced materials that can withstand extreme conditions—such as high temperatures and corrosive environments—necessitates the development of coatings with superior durability and performance. This requires significant advancements in PECVD technology, including the optimization of deposition parameters and the integration of novel materials. Similarly, in biomedicine, the requirements for biocompatibility and antimicrobial properties add another layer of complexity to the coating process.

Regulatory Compliance

Regulatory challenges are another critical aspect that cannot be overlooked. The stringent regulations governing the use of materials in new energy and biomedicine necessitate thorough validation and testing processes. For example, in the medical field, coatings must meet stringent FDA regulations, which involve extensive testing for safety and efficacy. In the new energy sector, regulatory bodies often impose strict standards to ensure the reliability and safety of energy storage and conversion systems.

Cross-Industry Integration

Furthermore, the integration of PECVD technology into these emerging fields requires collaboration across multiple disciplines. This includes not only the traditional areas of polymer materials science and plasma physics but also new areas such as bioengineering and renewable energy technologies. Such interdisciplinary collaboration is essential for overcoming the technical hurdles and developing innovative solutions that meet the specific needs of these industries.

In summary, while the expansion into new fields like new energy and biomedicine offers significant opportunities for growth, it also brings with it a unique set of technical and regulatory challenges that must be carefully navigated.

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Custom CVD Diamond Coating for Lab Applications

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine