Introduction to Powder Compaction Methods

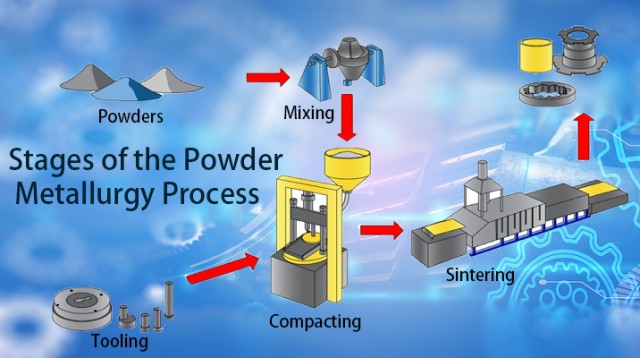

Powder compaction is a process used to form solid objects from powder. The process involves compressing the powder into a die, where it is subjected to high pressure to form a solid object. There are several powder compaction methods, including isostatic pressing, die compaction, extrusion, and injection molding. Each method has its advantages and disadvantages, and the choice of method depends on the specific application. Isostatic pressing is a popular powder compaction method that offers several advantages over other methods. It involves applying pressure uniformly from all directions, resulting in products with uniform density and strength.

Table of Contents

Comparison of Isostatic Pressing and Die Compaction

Overview

Isostatic pressing and die compaction are two of the most common powder compaction methods used in the manufacturing of laboratory equipment. They have their advantages and disadvantages, and the choice between them depends on the specific requirements of the laboratory equipment being produced.

Isostatic Pressing

Isostatic pressing is a method that applies pressure equally from all directions, resulting in parts with high density, uniformity, and strength. The compaction takes place under hydrostatic conditions, and the tooling consists of elastomeric molds rather than rigid dies. The range of ceramic products produced by the isostatic process is large, and it is used as an alternative production method to die compaction, extrusion, slip casting, and injection molding. The advantages of isostatic pressing are varied and can be summarized as follows:

- low distortion on firing

- consistent shrinkage on firing

- parts can be fired without drying

- lower levels of binder in the powder are possible

- most green (unfired) compacts can be machined

- low internal stresses in compact as pressed

- very large pressed part capability (wet bag)

- low tooling cost (wet bag)

- higher density for a given pressing pressure than can be achieved with mechanical pressing

- ability to press compacts of very high length-diameter ratio (> 200)

- ability to press parts with internal shapes, including threads, splines, serrations, and tapers

- ability to press long thin-walled parts

- ability to press weak powders

- ability to press a compact having two or more layers of powder possessing different characteristics.

![cold isostatic press]()

However, the disadvantages of isostatic pressing are lower accuracy of pressed surfaces adjacent to the flexible bag, relatively expensive spray-dried powder normally required for fully automatic dry bag presses, and lower production rates than for extrusion or die compaction.

Die Compaction

Die compaction, on the other hand, applies pressure only from one direction. It is used for producing simple shapes such as cylinders, blocks, and plates and is more cost-effective than isostatic pressing, making it ideal for mass production. However, die compaction is limited in terms of the complexity of the shapes that can be produced.

Comparison

In terms of the density distribution of cold-pressed parts, die-wall friction, which exerts a major influence, is absent in isostatic pressing. The elimination of die-wall lubricants also permits higher pressed densities and eliminates problems associated with lubricant removal prior to or during final sintering. Furthermore, if necessary, air can be evacuated from the loose powder before compaction. Consequently, isostatic compaction provides increased and more uniform density at a given compaction pressure and relative freedom from compact defects when applied to brittle or fine powders. Because of the uniform compaction pressure, the cross section-to-height ratio of the part is not a limiting factor as it is with uniaxial pressing. In addition, cold isostatic pressing can be used to compact more complex shapes than possible with uniaxial pressing. Die compaction, on the other hand, is more cost-effective than isostatic pressing and is ideal for mass production of simple shapes.

In summary, both methods have their advantages and disadvantages, and the choice between them depends on the specific requirements of the laboratory equipment being produced.

Advantages of Isostatic Pressing over Die Compaction

Isostatic pressing and die compaction are two popular methods in powder compaction, but isostatic pressing offers several advantages over die compaction.

Uniform Density and Improved Mechanical Properties

Isostatic pressing subjects the powder to equal pressure from all directions, resulting in uniform density and improved mechanical properties of the final product. In contrast, die compaction applies pressure only from one direction, leading to non-uniform density and weaker mechanical properties.

Accommodates Complex Shapes and Thin Walls

Isostatic pressing can also accommodate complex shapes and thin walls, which cannot be achieved through die compaction.

Versatility in Materials

Isostatic pressing can use a variety of materials, including ceramics, metals, and composites, while die compaction is limited to materials that can withstand the high pressure exerted during the process.

No Need for Binders

Isostatic pressing also eliminates the need for binders, which are often used in die compaction and can compromise the quality of the final product.

Cost-Effective for Large-Scale Production

Finally, isostatic pressing can achieve high production rates, making it a cost-effective option for large-scale production.

Overall, the advantages of isostatic pressing make it a preferred method for powder compaction in various industries, including aerospace, automotive, and medical devices.

Comparison of Isostatic Pressing and Extrusion

Introduction

Powder compaction is an essential process in the manufacturing of various industrial components. Isostatic pressing and extrusion are two common techniques used in powder compaction. In this section, we will compare and contrast the two methods to identify their unique advantages and disadvantages.

Isostatic Pressing

Isostatic pressing is a process in which a powder is subjected to high pressure from all directions to produce a uniform density. The process offers several advantages over extrusion, such as the ability to produce parts with complex shapes and better density uniformity. Additionally, isostatic pressing can be used to produce parts with a higher green strength, which reduces the risk of deformation during post-processing.

Extrusion

Extrusion involves forcing a powder through a die to produce a specific shape. It is a more cost-effective method for producing parts with simple shapes. However, extrusion is limited in terms of the materials that can be processed due to the need for lubrication, which can contaminate the powder. Moreover, extrusion can result in a non-uniform density distribution due to the directionality of the process.

Shape and Dimension

Isostatic pressing can produce parts with complex shapes with very high accuracy. On the other hand, extrusion is limited to simpler shapes and has less precision in the dimensions of the parts produced.

Density Uniformity

Isostatic pressing can achieve a higher level of density uniformity in the parts produced due to the pressure being applied from all directions. In contrast, extrusion can lead to non-uniform density distribution due to the directionality of the process.

Green Strength

Isostatic pressing can produce parts with higher green strength, which reduces the risk of deformation during post-processing. This is due to the uniform pressure applied from all directions. However, extruded parts may have lower green strength, making them more prone to deformation during post-processing.

Lubrication

Extrusion requires the use of lubrication to prevent the powder from sticking to the die, which can contaminate the powder. Isostatic pressing does not require lubrication, making it a cleaner process.

Cost

Extrusion is generally a more cost-effective method for producing parts with simpler shapes. Isostatic pressing is more expensive and requires specialized equipment.

Conclusion

In conclusion, both isostatic pressing and extrusion have their advantages and disadvantages in powder compaction. The choice of method depends on the specific requirements of the application, such as the desired shape, density, and cost-effectiveness. Isostatic pressing is a better choice for producing parts with complex shapes and higher density uniformity, while extrusion is more suited for producing parts with simpler shapes and lower cost.

Advantages of Isostatic Pressing over Extrusion

Isostatic pressing and extrusion are two popular methods of powder compaction used in the manufacturing industry. Both methods have their advantages, but isostatic pressing offers several advantages over extrusion.

Uniform Density and Precision

Isostatic pressing involves applying equal pressure to all sides of a powder compact, resulting in a uniform density and a high degree of precision. This process is ideal for creating complex shapes and achieving a high level of consistency in production.

Volume of Powder Processing

Another advantage of isostatic pressing over extrusion is the ability to compress a larger volume of powder at once. Isostatic presses use a flexible mold, allowing for a higher powder volume to be compressed at once. In contrast, extrusion requires the powder to be fed through a narrow die, limiting the amount of powder that can be processed at one time.

Handling a Wider Range of Materials

Isostatic presses are also capable of handling a wider range of materials than extrusion. This includes ceramics, metals, and alloys, making it a versatile method of powder compaction. Additionally, isostatic pressing produces components with a higher density, resulting in stronger and more durable finished products.

Cost-Effective

Although isostatic pressing is generally more expensive than extrusion, it can be more cost-effective in certain situations. For example, isostatic pressing can produce components with a higher level of precision, reducing the need for additional machining or finishing. This can lead to cost savings in the long run.

Consistency in Production

Isostatic pressing provides a higher level of consistency in production due to the uniform pressure applied to the powder compact. This results in a high degree of precision and consistency in the final product.

Complex Shapes

Isostatic pressing makes it practical to produce shapes and dimensions that are difficult or impossible to produce by other methods. This is because the flexible mold used in isostatic pressing can conform to complex shapes, resulting in a high degree of precision and consistency in production.

In conclusion, isostatic pressing offers several advantages over extrusion, including uniform density and precision, the ability to process a larger volume of powder, handling a wider range of materials, cost-effectiveness, consistency in production, and the ability to produce complex shapes. These advantages make isostatic pressing a popular choice for manufacturers in a variety of industries, including aerospace, defense, and automotive.

Conclusion: Why Isostatic Pressing is Better

In summary, the isostatic pressing method offers several advantages over other powder compaction methods such as die compaction, extrusion, and injection molding. Isostatic pressing produces parts with higher density, better surface finish, and more uniform properties. Additionally, isostatic presses can process a wide range of materials, including ceramics, metals, and composites. The ability to produce complex shapes and the high reproducibility of the process make isostatic pressing a preferred option for many industries, including aerospace, medical, and automotive. Therefore, if you are looking for a reliable and efficient powder compaction method, isostatic pressing is the way to go.

Related Products

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

Related Articles

- Understanding Isostatic Pressing: Process, Benefits, Limitations, and Applications

- Understanding the Isostatic Pressing Process and its Types

- How Isostatic Presses Help Eliminate Defects in Materials

- Comprehensive Guide to Isostatic Pressing:Processes, and Features

- Isostatic Pressing Technology: Revolutionizing Ceramic Material Densification