Introduction to Sputtering Targets

Manufacturing Methods

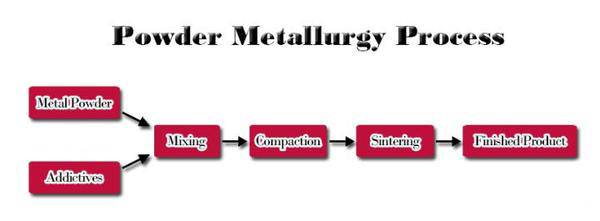

When it comes to producing sputtering targets, two primary manufacturing methods stand out: powder metallurgy and casting. Each method has its own set of advantages and is suited for different types of materials and applications.

Powder Metallurgy

This method is particularly favored for materials with high melting points, complex alloys, and rare precious metals. The process involves several intricate steps:

- Raw Material Preparation: High-purity powders are prepared using physical and chemical purification methods.

- Molding and Cold Pressing: The powders are compacted and bonded at room temperature to form a solid billet.

- Vacuum Hot Pressing: The billets are heated and pressed in a vacuum to prevent oxidation and enhance density.

- Hot Isostatic Pressing: Uniform high pressure and temperature are applied to improve material properties.

- Mechanical Processing: The material is machined to achieve the required dimensions.

- Soldering of Backing Plates: The machined target is welded to a metal plate for additional support and strength.

- Inspection: Quality checks are conducted, including welding, chemical analysis, metallographic analysis, and dimensional inspection.

- Cleaning and Shipping: The final cleaning and shipping of the target material.

Casting

On the other hand, casting is more suitable for materials that do not require the high precision and purity offered by powder metallurgy. This method involves melting the material and pouring it into a mold to form the target. While simpler and more cost-effective, casting may not achieve the same level of material integrity and purity as powder metallurgy.

Both methods play crucial roles in the manufacturing of sputtering targets, each catering to different material requirements and production needs.

Powder Metallurgy Method

Applicable Scenarios

The powder metallurgy method is particularly well-suited for the production of sputtering targets made from high melting point metals, complex alloys, and rare precious metals. These materials often present significant challenges in traditional manufacturing processes due to their unique physical and chemical properties.

For instance, high melting point metals such as tungsten and molybdenum require specialized techniques to handle their high temperatures and resistance to deformation. Powder metallurgy allows for the precise control of these materials' properties, ensuring that the final product meets the stringent requirements of various industrial applications.

Complex alloys, on the other hand, often involve multiple elements with differing melting points and reactivity. Powder metallurgy enables the homogeneous mixing of these elements at the particle level, leading to a more consistent and reliable final product. This method is crucial for alloys used in high-tech industries like aerospace and electronics.

Lastly, rare precious metals like platinum and gold are often in short supply and require efficient manufacturing processes to minimize waste. Powder metallurgy offers a cost-effective and environmentally friendly approach to processing these valuable materials, ensuring that every ounce is utilized to its fullest potential.

In summary, the powder metallurgy method stands out as the preferred choice for manufacturing sputtering targets from these challenging materials, offering precision, consistency, and efficiency.

Process Steps

The manufacturing of sputtering targets using powder metallurgy involves a series of meticulously planned steps. These steps are designed to ensure the production of high-quality targets that meet precise specifications and performance criteria.

-

Raw Material Preparation: The process begins with the selection and preparation of high-purity powders. These powders undergo rigorous purification through both physical and chemical methods to remove any impurities that could affect the final product's performance.

-

Molding and Cold Pressing: Once the raw materials are prepared, they are subjected to molding and cold isostatic press. This stage involves compacting the powder particles into a solid billet at room temperature, ensuring a strong bond between the particles without the need for high temperatures.

-

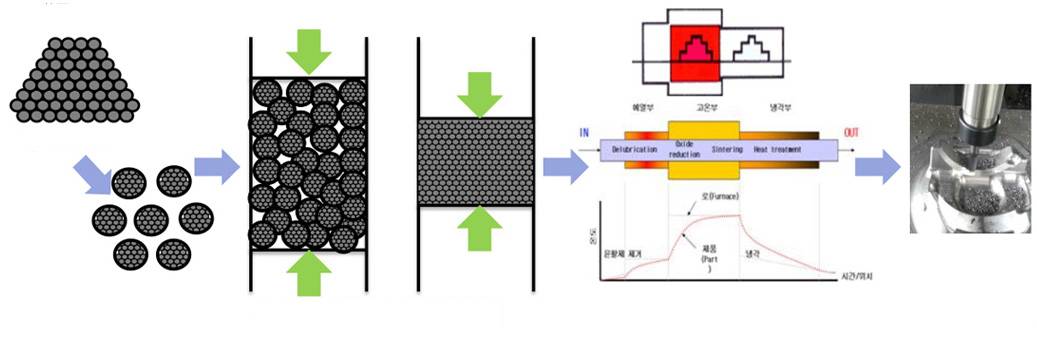

Vacuum Hot Pressing: The billet is then placed in a vacuum environment and subjected to both heat and pressure. This process helps to further compact the material and improve its density while preventing oxidation, which is crucial for maintaining the target's purity.

-

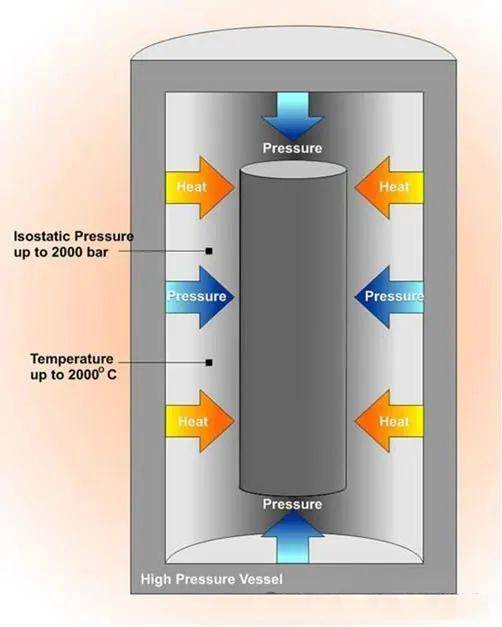

Hot Isostatic Pressing: Following vacuum hot pressing, the material undergoes hot isostatic pressing. This step applies uniform high pressure and temperature, significantly enhancing the material's properties, including its density and mechanical strength.

-

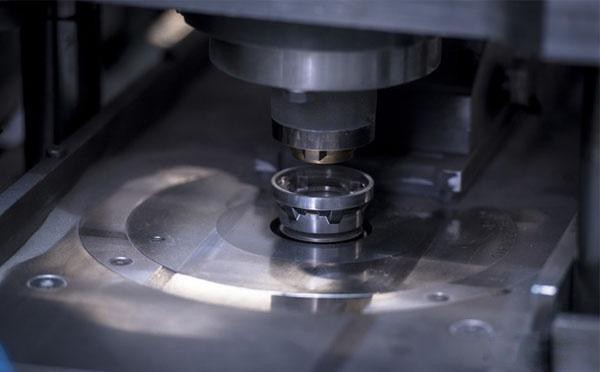

Mechanical Processing: After the pressing stages, the material is machined to achieve the exact dimensions required for the sputtering target. This precision machining ensures that the target meets the specific size and shape needed for its intended application.

-

Soldering of Backing Plates: The machined target is then welded to a metal backing plate. This step provides additional support and strength, ensuring the target can withstand the rigors of the sputtering process.

-

Inspection: Before the target is deemed ready for use, it undergoes a series of quality checks. These include welding inspections, chemical analyses, metallographic analyses, and dimensional inspections to ensure it meets all necessary standards.

-

Cleaning and Shipping: The final steps involve thorough cleaning of the target to remove any residual contaminants and packaging it for shipping. Proper cleaning and packaging are essential to protect the target from damage during transit and to ensure it arrives at its destination in pristine condition.

Detailed Process Steps

Raw Material Preparation

The preparation of raw materials is a critical initial step in the powder metallurgy process for manufacturing sputtering targets. This stage involves the meticulous purification of powders to achieve high levels of purity, which is essential for the performance and reliability of the final sputtering target. The purification methods employed can be broadly categorized into physical and chemical processes.

Physical purification techniques typically include methods such as vacuum distillation, zone refining, and electromagnetic separation. These methods are particularly effective for removing volatile impurities and segregating different materials based on their physical properties. For instance, vacuum distillation can effectively reduce the presence of gases and low-boiling-point impurities, while zone refining helps in eliminating solid impurities by leveraging the principle of selective melting and solidification.

On the other hand, chemical purification methods involve processes like solvent extraction, chemical vapor deposition, and electrochemical treatment. Solvent extraction, for example, uses selective solubility to separate impurities from the target material, while chemical vapor deposition can deposit ultra-pure layers onto the powder particles. Electrochemical treatments, such as electropolishing, can remove surface impurities and refine the particle morphology.

The choice of purification method often depends on the specific material and the desired level of purity. For high melting point metals, complex alloys, and rare precious metals, a combination of both physical and chemical methods is often employed to ensure that the final powder meets the stringent purity requirements necessary for high-performance sputtering targets.

Molding and Cold Pressing

Molding and cold pressing are critical initial steps in the powder metallurgy process for manufacturing sputtering targets. This stage involves the meticulous compacting and bonding of powder particles at room temperature to form a solid billet. The primary objective of this process is to create a dense, uniform structure that can withstand subsequent high-temperature and high-pressure treatments.

The cold pressing process typically employs hydraulic or mechanical presses to exert significant pressure on the powder particles. This pressure consolidates the particles, eliminating voids and ensuring a high degree of density. The resulting billet is a precursor to further processing steps, such as vacuum hot pressing and hot isostatic pressing, which refine the material's properties.

Key factors in the success of cold pressing include the homogeneity of the powder, the precision of the pressing equipment, and the control of environmental conditions to prevent contamination. The billet produced must be free from cracks and other defects, as these can compromise the integrity of the final sputtering target.

In summary, molding and cold pressing lay the foundation for the subsequent steps in the manufacturing of sputtering targets, ensuring a robust and homogeneous starting material.

Vacuum Hot Pressing

Vacuum hot pressing is a specialized technique used to densify and shape materials in a controlled, oxygen-free environment. This process is particularly crucial for materials that require high density and pore-free structures to achieve optimal mechanical, thermal, or optical properties. The method involves simultaneous heating and pressing of the material under vacuum conditions, which facilitates the mass transfer of powder particles through processes like diffusion and flow, thereby enhancing the densification of the target material.

Key Features and Applications

- Material Compatibility: Suitable for a range of materials, including metals and ceramics, that are difficult to sinter due to low diffusion coefficients or require pore-free structures.

- Shape Complexity: Primarily used for simple shapes like plates, blocks, and cylinders. However, with advanced die designs, more complex shapes can also be produced.

- Pressing Force and Temperature: Operates with pressing forces ranging from 50 kN to 800 tons and temperatures up to 2600°C, applicable for components with diameters from 700mm to 1500mm.

Advantages

- Enhanced Densification: The simultaneous application of heat and pressure accelerates the sintering process, leading to higher densities.

- Temperature and Time Efficiency: Reduces the sintering temperature and time compared to traditional methods.

- Grain Size Control: Effective in restraining grain growth, which is crucial for maintaining material integrity and performance.

Applications in Ceramics

- Composite Materials: Includes MMC (Metal Matrix Composites) and CMC (Ceramic Matrix Composites).

- Advanced Ceramics: Such as silicon nitride, Al2O3, TiC/TiN, and sialon used in cutting tools, heavy-duty valve components, and wear-resistant parts.

- Functional Ceramics: Examples include PLZT (lead-lanthanum-zirconate-titanate) and other high-performance ceramics used in various industrial applications.

Vacuum hot pressing is a cornerstone in the production of high-quality sputtering targets, ensuring that the final products meet stringent performance and structural requirements.

Hot Isostatic Pressing

Hot isostatic pressing (HIP) is a sophisticated manufacturing process that employs both elevated temperature and uniform gas pressure to enhance the properties of various materials, including metals, ceramics, polymers, and composites. This method is particularly effective in eliminating porosity and increasing the density of these materials, thereby significantly improving their mechanical properties and workability.

The process involves the use of a mold, typically made from sheet metal with a high melting point to ensure structural integrity throughout the operation. In certain specialized applications, ceramic molds may also be employed. The mold is filled with the material to be processed and then subjected to an inert gas, such as argon, or a glass-like fluid, which applies the isostatic pressure. A common operational setting for HIP involves pressures of around 15,000 lb/in² (100 MPa) at temperatures exceeding 2000°F (1100°C).

HIP is extensively used in several critical applications:

- Elimination of Microshrinkage in Castings: This ensures the integrity and reliability of cast components.

- Consolidation of Powders and Diffusion Bonding: Often referred to as cladding, this process is essential for creating robust and dense structures from powdered materials.

- Sintering in Powder Metallurgy: HIP is integral to the sintering process, where it aids in the formation of dense, strong parts from metal powders.

- Pressure-Assisted Brazing: Enhances the bond strength in brazed joints.

- Fabrication of Metal Matrix Composites: Enables the creation of advanced materials with superior mechanical properties.

By combining high temperature with uniform pressure, HIP not only refines the material's internal structure but also enhances its overall performance and durability, making it indispensable in high-precision manufacturing processes.

Mechanical Processing

Mechanical processing is a critical step in the manufacturing of sputtering targets, ensuring that the final product meets precise dimensional requirements. This process involves the use of various machining techniques to shape the target material into its final form. The primary goal is to achieve the exact dimensions and surface finish necessary for optimal performance in sputtering applications.

There are several key techniques employed during mechanical processing:

-

Turning and Milling: These operations are used to remove excess material and shape the target into its desired form. Turning involves rotating the workpiece against a cutting tool, while milling uses a rotating tool to remove material from the workpiece.

-

Grinding: This technique is employed to achieve high precision and a smooth surface finish. Grinding involves the use of an abrasive wheel to remove small amounts of material, ensuring that the target meets the required tolerances.

-

Lapping and Polishing: These final steps are crucial for achieving the highest surface quality. Lapping involves the use of a fine abrasive to further refine the surface, while polishing uses a smoother abrasive to achieve a mirror-like finish.

The choice of machining technique depends on the material properties and the specific requirements of the sputtering target. For instance, high melting point metals and complex alloys may require specialized machining processes to ensure that the material is not compromised during processing.

In summary, mechanical processing is a meticulous process that ensures the sputtering target is perfectly suited for its intended application, balancing precision, surface quality, and material integrity.

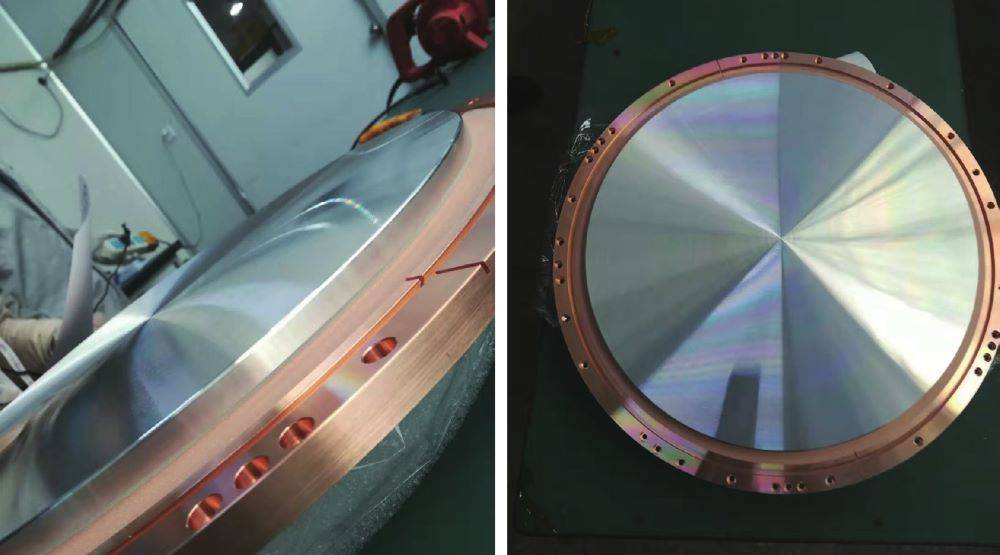

Soldering of Backing Plates

The process of soldering backing plates is a critical step in the manufacturing of sputtering targets. This step involves the meticulous welding of the machined target to a robust metal plate, ensuring both support and enhanced structural integrity. The metal plate serves as a foundational layer, providing the necessary strength to withstand the high-stress environments typically encountered during sputtering processes.

To achieve a secure and durable bond, advanced welding techniques are employed. These techniques not only ensure that the target remains firmly attached to the backing plate but also prevent any potential detachment during operation. The choice of welding method is crucial, as it must accommodate the specific material properties of the target and the backing plate, ensuring a seamless integration without compromising the target's performance.

Moreover, the soldering process is executed under controlled conditions to minimize the risk of defects such as cracks or voids. This precision is essential for maintaining the target's integrity and ensuring its longevity in high-vacuum environments. The backing plate's role extends beyond mere support; it also aids in heat dissipation, which is vital for the target's operational efficiency and lifespan.

In summary, the soldering of backing plates is a meticulous process that combines precision welding techniques with careful material selection to ensure the target's structural integrity and operational durability. This step is integral to the overall manufacturing process, contributing significantly to the quality and reliability of the final sputtering target.

Inspection

The final stage in the manufacturing process of sputtering targets involves rigorous quality inspections to ensure the integrity and performance of the finished product. These inspections encompass several critical areas:

- Welding Inspection: Ensuring that the welding of the target to the backing plate is flawless, maintaining structural integrity and preventing any potential leaks or failures.

- Chemical Analysis: Verifying the chemical composition of the target material to confirm it aligns with the specified standards and requirements.

- Metallographic Analysis: Examining the microstructure of the material to assess grain size, homogeneity, and any potential defects that could affect performance.

- Dimensional Inspection: Measuring the dimensions of the target to ensure they meet the precise specifications, crucial for optimal sputtering performance.

These inspections are not just routine checks but are essential for guaranteeing the quality and reliability of the sputtering targets, thereby ensuring their effectiveness in various industrial applications.

Cleaning and Shipping

The final stages of the manufacturing process for sputtering targets involve meticulous cleaning and careful shipping to ensure the integrity and quality of the target material.

Cleaning Process

Before the target material is deemed ready for shipment, it undergoes a thorough cleaning process to remove any residual contaminants that may have accumulated during the manufacturing stages. This cleaning process typically includes:

- Surface Cleaning: Utilizing specialized solvents and techniques to remove any surface contaminants, ensuring a pristine surface for optimal sputtering performance.

- Chemical Cleaning: Applying chemical treatments to neutralize any potential corrosive elements that could affect the target's longevity and effectiveness.

- Final Inspection: Conducting a final visual and tactile inspection to confirm that the target meets all cleanliness standards.

Shipping Considerations

Once the target material has been thoroughly cleaned, it is carefully packaged and prepared for shipping. Key considerations during this phase include:

- Packaging: The target is securely packaged in protective materials to prevent any damage during transit. This often includes the use of shock-absorbing materials and moisture-proof wrapping.

- Handling: Special handling instructions are provided to the logistics team to ensure that the target is not subjected to excessive force or improper storage conditions.

- Documentation: Detailed documentation accompanies the shipment, including cleaning certificates, quality assurance reports, and handling guidelines.

These final steps are crucial to maintain the high standards required for sputtering targets, ensuring they arrive at their destination in optimal condition for use.

Related Products

- Assemble Square Lab Press Mold for Laboratory Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Carbide Lab Press Mold for Laboratory Applications

Related Articles

- Comprehensive Guide to Cylindrical Lab Electric Heating Press Mold: Technology and Applications

- Battery sealing machine operating steps and precautions

- Pressing Powder Samples and Molding Polymer Films: A Comprehensive Guide

- Comprehensive Guide to Metal Mold Pressing: Techniques, Equipment, and Applications

- The Benchtop KBr Pellet Press: An Efficient Tool for Laboratory Use