Introduction to Spark Plasma Sintering (SPS)

Spark Plasma Sintering (SPS) has emerged as a revolutionary sintering technique that offers unparalleled advantages in materials processing. This comprehensive guide delves into the fundamentals of SPS, exploring its definition, historical evolution, and key characteristics. By comparing SPS with traditional sintering methods, you will gain a deep understanding of its distinctive features and the benefits it brings to the world of materials science.

Advantages and Applications of SPS Furnaces

Spark plasma sintering (SPS) furnaces offer a unique combination of advantages that make them ideal for a wide range of materials processing applications. These advantages include:

- Rapid sintering: SPS furnaces can achieve sintering temperatures and rates that are much higher than conventional sintering processes. This can significantly reduce processing time and increase productivity.

- Enhanced material properties: SPS furnaces can produce materials with improved mechanical, thermal, and electrical properties compared to conventional sintering processes. This is due to the unique combination of high temperatures and pressures used in SPS.

- Versatility: SPS furnaces can be used to sinter a wide variety of materials, including metals, ceramics, and composites. This makes them a versatile tool for a variety of applications.

SPS furnaces are used in a variety of industries, including:

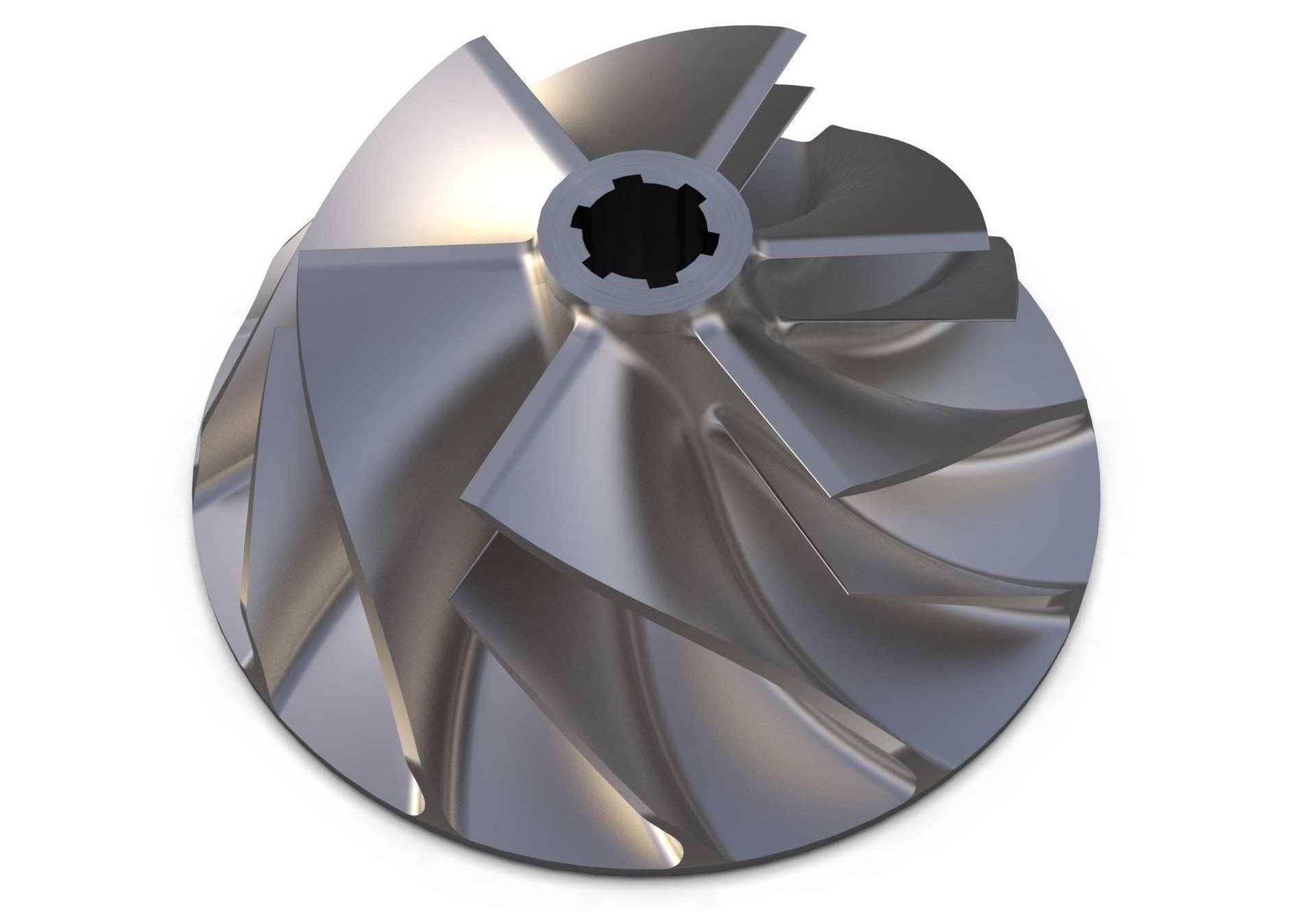

- Aerospace: SPS furnaces are used to produce high-performance materials for aerospace applications, such as turbine blades and rocket nozzles.

- Automotive: SPS furnaces are used to produce materials for automotive applications, such as engine components and brake rotors.

- Biomedical: SPS furnaces are used to produce materials for biomedical applications, such as dental implants and surgical instruments.

- Electronics: SPS furnaces are used to produce materials for electronic applications, such as semiconductors and capacitors.

The applications of SPS furnaces are constantly expanding as new materials are developed and new applications are discovered. SPS furnaces are a powerful tool for materials processing, and they are likely to play an increasingly important role in the future.

The Spark Plasma Sintering Process

Introduction Spark Plasma Sintering (SPS), also known as FAST (Field Assisted Sintering Technique) or Flash Sintering, is a cutting-edge powder metallurgy technique that combines uniaxial pressure with high-intensity, low-voltage, pulsed current. SPS enables the rapid densification and sintering of powders into dense, homogeneous bulk materials.

Mechanism During SPS, a pulsed direct current is passed through the powder within a die. The current generates a plasma discharge between the powder particles, leading to rapid heating and localized melting. This localized heating promotes rapid densification and sintering, resulting in materials with exceptional microstructures and properties.

Advantages SPS offers several advantages over traditional sintering methods:

- High heating rates: SPS allows for faster heating rates, significantly reducing processing time.

- Short processing times: The rapid heating and densification processes in SPS result in shorter processing times compared to conventional sintering techniques.

- Low sintering temperatures: SPS can achieve sintering at lower temperatures than traditional methods, reducing energy consumption and minimizing grain growth.

- Improved material properties: SPS enables the fabrication of materials with enhanced density, fine grain size, and superior mechanical, electrical, and thermal properties.

Applications SPS has found widespread applications in various fields, including:

- Materials science: Development of advanced ceramic, metallic, and composite materials.

- Nanotechnology: Fabrication of nanoscale materials and devices.

- Engineering: Production of high-performance components for aerospace, automotive, and biomedical industries.

Process Parameters The SPS process involves several key parameters that influence the final material properties:

- Temperature: The temperature during SPS affects the densification rate and grain growth.

- Pressure: The uniaxial pressure applied during SPS promotes powder compaction and densification.

- Heating rate: The heating rate determines the speed of the sintering process.

- Pulsed current: The intensity and duration of the pulsed current affect the plasma discharge and heating.

Optimization Optimizing the SPS process parameters is crucial to achieve the desired material properties. Careful consideration of powder characteristics, die design, and process parameters ensures the production of high-quality materials with tailored properties.

Equipment and Components of SPS Furnaces

Spark Plasma Sintering (SPS) furnaces are advanced sintering systems that employ a unique combination of pressure, heat, and electric current to rapidly consolidate powdered materials. Understanding the essential components of SPS furnaces is crucial for optimizing their performance and achieving desired sintering results.

Sintering Chamber

The sintering chamber is the heart of the SPS furnace. It houses the powder material and provides a controlled environment for the sintering process. The chamber is typically made of high-temperature resistant materials such as graphite or molybdenum and is designed to withstand the extreme temperatures and pressures encountered during sintering.

Power Supply

The power supply provides the electrical energy required for the SPS process. It generates a high-voltage, pulsed DC current that is applied to the electrodes of the furnace. The power supply controls the pulse duration, pulse frequency, and voltage, which allows for precise control of the sintering conditions.

Uniaxial Press

The uniaxial press applies pressure to the powder material during sintering. The pressure helps to consolidate the particles, promote plastic flow, and reduce porosity. The press is typically hydraulic or mechanical and can apply pressures ranging from a few MPa to several hundred MPa.

Temperature Control System

The temperature control system regulates the temperature of the sintering chamber. It consists of thermocouples, heating elements, and a controller. The controller monitors the temperature and adjusts the heating elements to maintain the desired temperature profile throughout the sintering cycle.

Atmosphere Control System

The atmosphere control system regulates the composition of the gas inside the sintering chamber. It can be used to create a vacuum, inert atmosphere, or a specific gas mixture. The atmosphere control system is essential for preventing oxidation or contamination of the powder material during sintering.

Other Components

In addition to these core components, SPS furnaces may also include other auxiliary components such as:

- Gas flow control system: Regulates the flow of gases into and out of the sintering chamber.

- Vacuum system: Creates and maintains a vacuum inside the chamber for vacuum sintering processes.

- Data acquisition system: Records and monitors process parameters such as temperature, pressure, and pulse current.

- Safety systems: Protects the operator and equipment from potential hazards such as overheating or electrical shock.

By understanding the functions and interactions of these components, users can optimize the SPS process, achieve high-quality sintered products, and extend the life of their equipment.

Advanced Features and Capabilities

Spark Plasma Sintering (SPS) furnaces offer a range of advanced features and capabilities that enhance the sintering process, enabling the production of high-performance materials with unique properties.

Vacuum Sintering:

SPS furnaces can operate under vacuum conditions, removing oxygen contamination from the sintering atmosphere. This is crucial for materials that are sensitive to oxidation, such as metals and alloys. Vacuum sintering prevents the formation of oxides on the surface of the sintered material, resulting in improved mechanical properties and reduced porosity.

Hot Pressing:

SPS furnaces incorporate a uniaxial press that applies pressure during the sintering process. This pressure assists in the plastic flow of the material, enhancing densification and reducing the formation of defects. Hot pressing is particularly beneficial for materials that are difficult to densify using conventional sintering methods.

Controlled Atmosphere Processing:

SPS furnaces allow for precise control of the atmosphere surrounding the sintering material. This enables the introduction of specific gases, such as nitrogen or hydrogen, to create a controlled atmosphere that optimizes the sintering process. Controlled atmosphere processing can enhance the properties of the sintered material, such as its electrical conductivity or corrosion resistance.

Benefits of Advanced SPS Features:

- Faster Sintering Times: Vacuum sintering and hot pressing significantly reduce sintering times compared to conventional methods, leading to increased productivity and reduced manufacturing costs.

- Lower Sintering Temperatures: SPS furnaces can achieve sintering at lower temperatures than traditional processes, minimizing thermal degradation and preserving delicate materials.

- Increased Density and Strength: Hot pressing and controlled atmosphere processing enhance densification and reduce porosity, resulting in stronger and more durable materials.

- Unique Material Properties: SPS enables the production of materials with tailored properties that are not achievable through other sintering methods.

- Broad Material Compatibility: SPS is versatile and can be used to sinter a wide range of materials, including metals, ceramics, and composites.

Applications of SPS Furnaces in Research and Industry

SPS furnaces, employing Spark Plasma Sintering technology, have revolutionized the production of advanced materials, composites, and electronic devices. Their unique capabilities offer numerous advantages in various research and industrial sectors.

Energy Storage

SPS furnaces are instrumental in developing high-capacity lithium-ion batteries and other advanced energy storage materials. The precise control of sintering parameters enables the creation of materials with enhanced electrochemical performance and extended cycle life.

Biomedical Engineering

In the field of biomedical engineering, SPS furnaces play a crucial role in the fabrication of porous ceramics for drug delivery and scaffolds for tissue engineering. The ability to sinter materials at lower temperatures preserves the delicate structures and properties required for these applications.

Advanced Ceramics

SPS furnaces facilitate the production of high-temperature superconductors and high-performance piezoelectric ceramics. By applying pressure and pulsed DC current, these furnaces enable the densification of advanced ceramics, resulting in improved electrical and mechanical properties.

Intermetallics

SPS is ideal for synthesizing intermetallic alloys with exceptional mechanical, thermal, and electrical properties. The controlled heating and cooling cycles promote the formation of unique and metastable phases, unlocking new possibilities for alloy design.

Composites

SPS furnaces excel in producing reinforced ceramics and metals with enhanced mechanical properties. By combining different materials, such as ceramics and metals, composites with tailored properties can be fabricated, meeting specific application requirements.

In addition to these specific applications, SPS furnaces offer broader advantages that make them a valuable tool in research and industry:

- Shorter Cycle Times: Sintering cycles are significantly reduced compared to conventional processes, leading to increased productivity and rapid material development capabilities.

- Lower Sintering Temperatures: SPS furnaces operate at lower temperatures than traditional sintering methods, reducing energy consumption and preserving material properties.

- Versatility: SPS can densify a wide range of materials, from low melting point metals to ultra-high temperature ceramics, and can even bond dissimilar materials with nonuniform temperatures.

- High-Precision Process Control: Precise control over sintering parameters ensures optimal outcomes, preserving the desired material properties and enabling the production of complex structures.

Selection and Maintenance of SPS Furnaces

SPS furnaces, renowned for their rapid sintering speeds and exceptional output compactness, have emerged as the latest advancement in high-speed metal sintering furnaces. These vacuum sintering furnaces excel in sintering various materials, including nanophase materials, functionally graded materials (FGMs), nanoscale thermoelectric materials, rare earth permanent magnets, target materials, nonequilibrium materials, and medical implants.

Criteria for SPS Furnace Selection

When selecting an SPS furnace, careful consideration should be given to specific requirements and applications. To ensure optimal performance and alignment with operational needs, the following criteria should be evaluated:

- Heating rate: SPS furnaces are characterized by their high heating rates, significantly reducing sintering time.

- Pressure: The applied pressure during sintering influences the density and microstructure of the final product.

- Temperature uniformity: Uniform temperature distribution within the furnace chamber is crucial for consistent and high-quality sintering.

- Gas flow control: The ability to control gas flow and composition is essential for achieving desired material properties.

- Automation: Automated systems enhance process control, precision, and reproducibility.

- Sample size and shape: Furnace dimensions and sample handling capabilities should accommodate the size and shape of the materials being sintered.

- Safety features: Robust safety mechanisms are paramount to ensure operator safety and prevent accidents.

- Maintenance requirements: Consider the frequency and complexity of maintenance procedures to minimize downtime and operational costs.

- Energy efficiency: Energy consumption and efficiency are important factors to optimize operating expenses.

- Supplier reputation and support: Choosing a reputable supplier with a proven track record and comprehensive support services ensures reliable performance and minimizes disruptions.

Maintenance of SPS Furnaces

Preventative maintenance is essential for maximizing SPS furnace performance and longevity. Regular inspections, servicing, and timely repairs can significantly extend furnace life and minimize the risk of major mechanical failures.

- Regular inspections: Conduct regular visual inspections to identify any potential issues, such as loose connections, wear and tear, or signs of damage.

- Scheduled servicing: Follow recommended servicing schedules to ensure proper functioning of all components, including temperature sensors, heating elements, and gas lines.

- Component replacement: Monitor the lifespan of critical components, such as heating elements and seals, and replace them before they fail to prevent costly repairs or downtime.

- Emergency repairs: Address any unexpected faults promptly to minimize production disruptions and potential safety hazards.

- Maintenance records: Maintain accurate records of all inspections, servicing, and repairs to facilitate problem diagnosis and anticipate future maintenance needs.

By implementing a comprehensive maintenance plan, businesses can ensure optimal performance of their SPS furnaces, minimize downtime, and maximize productivity.

Conclusion: The Future of SPS Technology

The future of SPS technology holds immense promise for the advancement of materials science and engineering. With ongoing research and development, SPS furnaces are expected to play an increasingly vital role in the production of innovative materials with tailored properties. The versatility and precision of SPS technology will continue to drive its adoption across diverse industries, enabling the creation of advanced composites, electronic devices, and other cutting-edge products. As SPS technology continues to evolve, we can anticipate even more groundbreaking applications and discoveries that will shape the future of manufacturing and innovation.

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

Related Articles

- Comprehensive Guide to Spark Plasma Sintering Furnaces: Applications, Features, and Benefits

- Dental Sintering Furnaces The Impact on Restoration Quality and Durability

- Understanding Saturated Calomel Reference Electrodes: Composition, Uses, and Considerations

- Understanding the PECVD Method

- An In-depth Analysis of Hot Pressing Technology and Its Applications