The Illusion of Stillness

In laboratory science, we often equate stability with precision. We place a sample in a box furnace, close the door, and assume that if the display reads 1000°C, the sample is experiencing 1000°C.

But heat is not a static object; it is energy in transit.

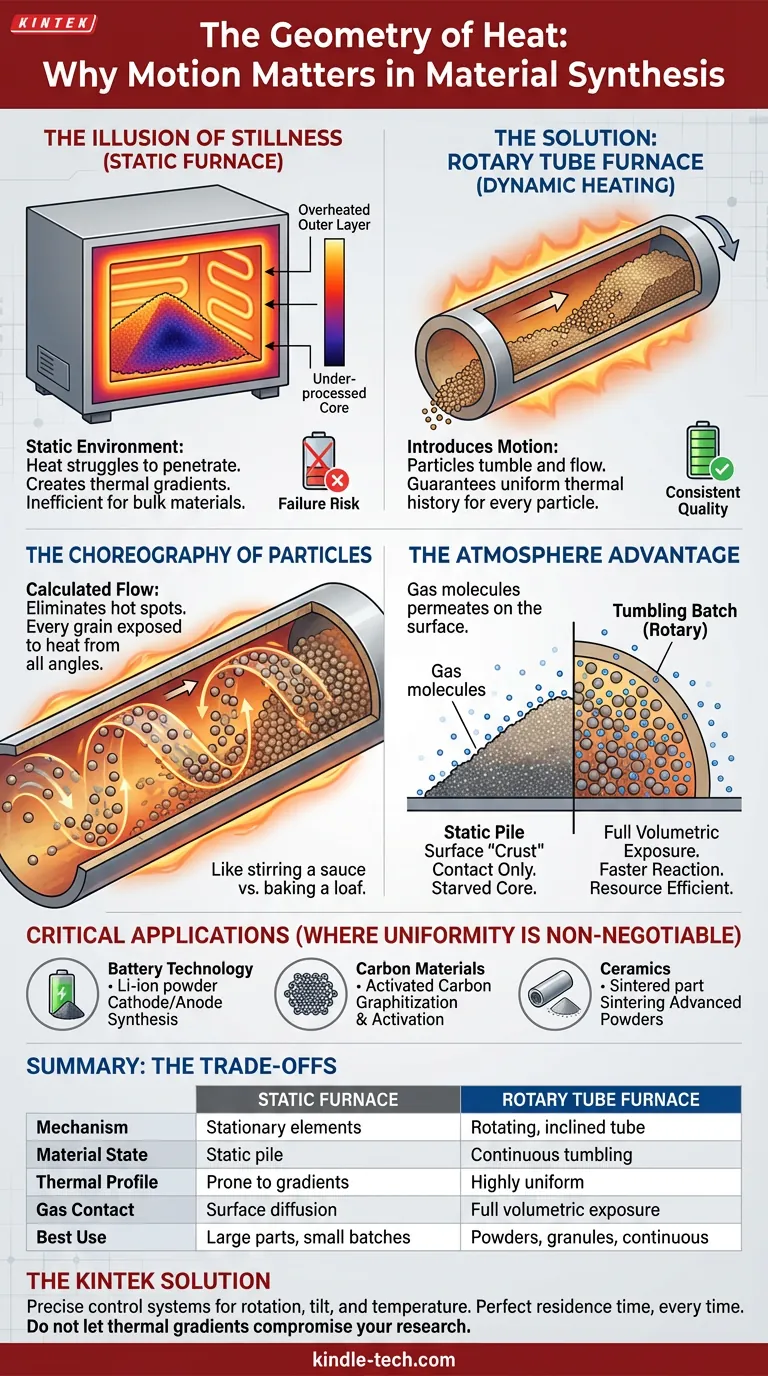

In a static environment, heat struggles to penetrate the center of a material pile. The outer layer overheats while the core remains under-processed. In high-stakes applications like battery material synthesis, this gradient isn't just an inefficiency—it is a failure of the system.

Enter the Rotary Tube Furnace.

It solves a fundamental physics problem not by adding more heat, but by adding motion. By accepting the mechanical complexity of rotation, it achieves what static furnaces cannot: the guarantee that every single particle shares the exact same thermal history.

The Choreography of Particles

The rotary tube furnace is defined by a deceptively simple mechanism: a cylindrical tube, lined with refractory material, rotating slowly at a slight incline.

It is engineering designed to fight gravity and stagnation.

As the tube turns, the material inside doesn't just sit; it tumbles. It cascades over itself, moving gradually from the higher entry point to the lower exit. This is not random movement. It is a calculated flow that exposes the material to the heat source from every conceivable angle.

Why Dynamic Heating Wins

The difference between static and dynamic heating is the difference between baking a loaf of bread and stirring a sauce.

- Static Furnaces: Rely on thermal conduction through the material itself. This is slow and often uneven.

- Rotary Furnaces: Rely on individual particle exposure. Every grain is brought to the surface, heated, and then folded back into the mass.

This "tumbling" action eliminates hot spots. It ensures that the particle in the center of the batch at minute one is on the surface at minute two.

The Atmosphere Advantage

Heat is rarely the only variable. In advanced material processing, chemistry is king.

Many processes require the material to interact with a specific gas atmosphere (such as nitrogen, hydrogen, or argon). In a static pile, gas only touches the surface "crust." The material underneath is starved of the reaction it needs.

The rotary furnace changes the surface area equation.

Because the particles are constantly airborne or cascading, the gas permeates the entire batch. This leads to two critical efficiency gains:

- Reaction Speed: Chemical conversion happens faster because diffusion barriers are removed.

- Resource Efficiency: You often need less process gas to achieve the same result.

Where Uniformity is Non-Negotiable

This technology is not a universal hammer for every nail. It is a scalpel designed for specific, granular materials.

The rotary tube furnace excels where consistency dictates performance.

Critical Applications

- Battery Technology: Synthesis of cathode and anode materials (Li-ion battery powders). Even a slight inconsistency here leads to reduced battery life.

- Carbon Materials: Graphitization and activation processes where surface structure is everything.

- Ceramics: Sintering of advanced ceramic powders.

The Limitations of Motion

Understanding the tool means understanding its limits. The rotary furnace introduces mechanical complexity—drive systems, seals, and motors—that static furnaces avoid.

It is not suitable for:

- Large, singular components.

- Fragile structures that cannot withstand tumbling.

- Materials that become sticky or viscous at high temperatures.

Summary: The Trade-Offs of Dynamics

To decide if this complexity is worth the investment, compare the operational realities.

| Feature | Static Furnace | Rotary Tube Furnace |

|---|---|---|

| Mechanism | Stationary heating elements. | Rotating, inclined tube. |

| Material State | Static pile or single part. | Continuous tumbling flow. |

| Thermal Profile | Prone to gradients (hot outside, cold inside). | Highly uniform; every particle treated equally. |

| Gas Contact | Surface diffusion only. | Full volumetric exposure. |

| Best Use | Large parts, small batches. | Powders, granules, continuous production. |

The KINTEK Solution

At KINTEK, we understand that "good enough" is rarely acceptable in modern materials science. Whether you are developing next-generation battery anodes or refining ceramic powders, the uniformity of your heat treatment defines the quality of your final product.

We specialize in high-precision lab equipment that bridges the gap between raw chemistry and engineering reality.

Our rotary tube furnaces are designed with precise control systems to manage rotation speed, tilt angle, and temperature profiles, ensuring your residence time is perfect, every time.

Do not let thermal gradients compromise your research.

Visual Guide

Related Products

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace