The Invisible Variable

In the laboratory, we tend to obsess over variables. We meticulously calculate molarities. We obsess over voltage parameters. We treat the hypothesis with reverence.

But we often ignore the vessel.

The side-window optical electrolytic cell is not merely a container; it is a lens through which you observe chemical truth. When that lens is dirty, the truth is distorted.

The difference between a breakthrough and an anomaly often comes down to a microscopic layer of residue left on a quartz window three days ago. Maintenance is not a chore. It is the calibration of your instrument's reality.

Here is how to maintain the integrity of your system, and by extension, your data.

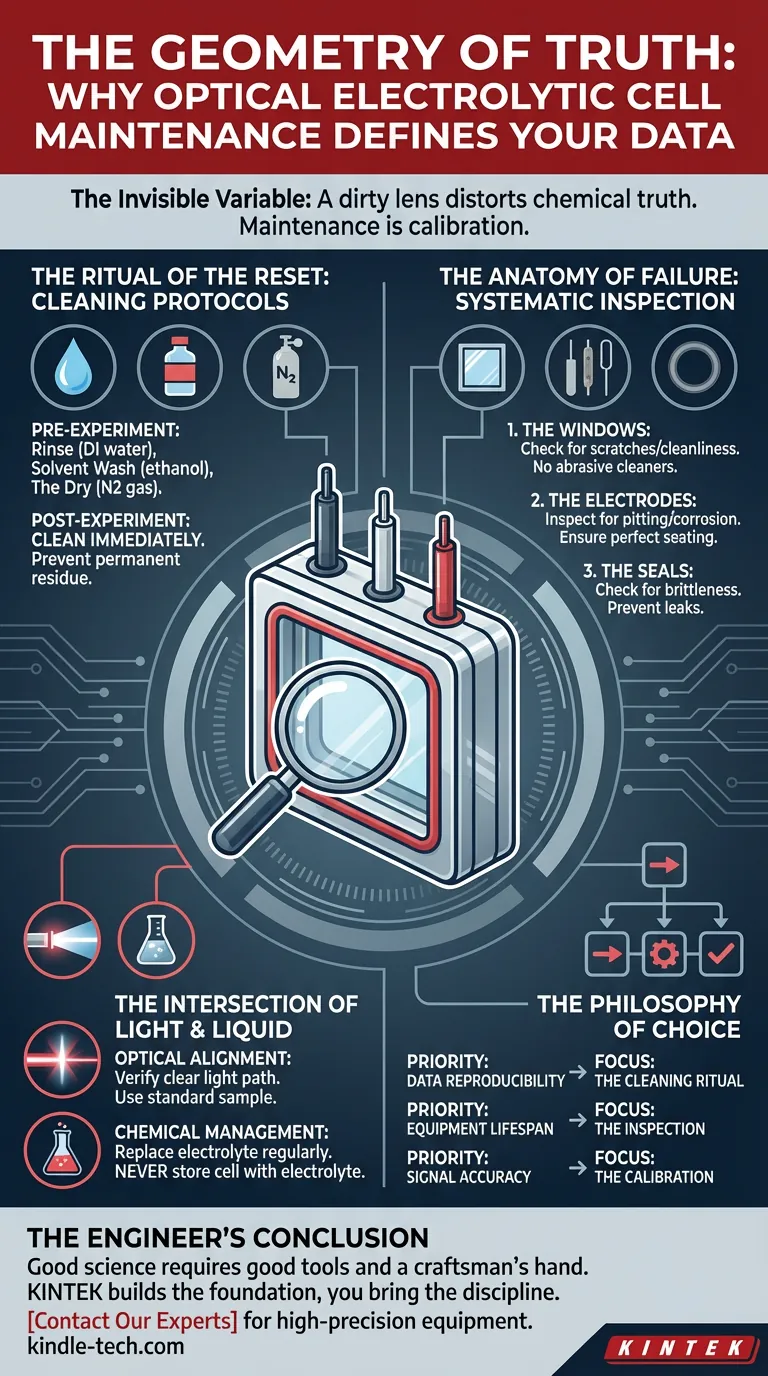

The Ritual of the Reset: Cleaning Protocols

Entropy is the enemy of the electrochemical cell. Every experiment leaves a ghost behind—salts, reaction byproducts, and organic residues.

If you do not exorcise these ghosts, they become part of your next experiment.

Pre-Experiment: The Tabula Rasa

Before you pour a single drop of electrolyte, you must ensure the cell has no memory of the past.

- Rinse: Use distilled or deionized water to flush surface particulates.

- Solvent Wash: Soak with an organic solvent (like ethanol) to dissolve stubborn organic residues.

- The Dry: Use a stream of high-purity nitrogen gas. Air drying leaves water spots; nitrogen leaves a void ready to be filled.

Post-Experiment: The Race Against Time

The most dangerous moment for a cell is the minute the experiment ends.

If you walk away for lunch, salts dry. Byproducts harden. The glass stains. Cleaning must be immediate. A delay converts a simple rinse job into a permanent scratch on your optical window.

The Anatomy of Failure: Systematic Inspection

Complexity disguises failure. A system looks fine until it isn't. To prevent catastrophic data loss, you must inspect the three points of vulnerability.

1. The Windows (The Eyes)

Your spectroelectrochemical data relies on light passing uninhibited through the cell.

- Check for transparency and cleanliness.

- Look for scratches. A scratch on the body is cosmetic; a scratch on the window is a prism that scatters your data.

- Never use abrasive cleaners. You cannot scrub a scratch away; you can only create more.

2. The Electrodes (The Hands)

Electrodes do the heavy lifting. They are consumables, not heirlooms.

- Inspect working and counter electrodes for pitting or corrosion.

- Check the reference electrode for physical wear.

- Ensure the seating is perfect. A loose connection introduces resistance, creating noise where there should be signal.

3. The Seals (The Skin)

The O-ring is the only thing standing between a controlled environment and a toxic leak.

- Check for brittleness or deformation.

- A compromised seal allows electrolyte to creep out, damaging the cell body and surrounding instrumentation.

The Intersection of Light and Liquid

Spectroelectrochemistry is a delicate marriage of optics and chemistry. Both systems must be calibrated to speak the same language.

Optical Alignment

You must prove the path is clear. Regularly verify that the light beam passes accurately through the sample. Use a standard sample with known absorbance to test the baseline. If the signal deviates, the cell is misaligned.

Chemical Management

The electrolyte is the blood of the system.

- Replace it based on usage frequency.

- Accumulated impurities alter optical properties.

- Crucial Rule: Never store the cell with electrolyte inside. It leads to electrode corrosion and seal degradation. Always disassemble, clean, and dry for storage.

The Philosophy of Choice

How you maintain your equipment depends on what you value most. Every action is a vote for the type of scientist you want to be.

| If your priority is... | Then your focus must be... |

|---|---|

| Data Reproducibility | The Cleaning Ritual. Standardized pre- and post-cleaning protocols eliminate variables between runs. |

| Equipment Lifespan | The Inspection. Catching seal brittleness or body cracks early prevents total system failure. |

| Signal Accuracy | The Calibration. Obsessive checking of the optical path and electrode integrity ensures the signal is real. |

The Engineer's Conclusion

Good science requires good tools. But even the best tools require a craftsman's hand.

At KINTEK, we build lab equipment designed to withstand the rigors of research, but we know that the hardware is only half the equation. The other half is the discipline you bring to the bench.

Whether you need high-precision electrolytic cells or the consumables to keep them running, we provide the foundation for your experiments.

Contact Our Experts today to secure the right equipment for your lab and ensure your data remains the truth, the whole truth, and nothing but the truth.

Visual Guide

Related Products

- Side Window Optical Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell with Five-Port

- Super Sealed Electrolytic Electrochemical Cell

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Thin-Layer Spectral Electrolysis Electrochemical Cell

Related Articles

- Advanced Electrolytic Cell Techniques for Cutting-Edge Lab Research

- The Silent Dialogue: Mastering Control in Electrolytic Cells

- Understanding Electrolytic Cells and Their Role in Copper Purification and Electroplating

- Understanding Quartz Electrolytic Cells: Applications, Mechanisms, and Advantages

- Electrochemistry The Science Behind Electrochemical Cells