The Invisible Cost of Contamination

In high-stakes engineering, what isn't there is often more important than what is.

When you look at a vacuum furnace, you see a steel vessel designed to withstand pressure. But the real story happens inside, in the "hot zone." Here, the battle isn't just against temperature; it is a battle against entropy and contamination.

For industries like aerospace and medical technology, a microscopic speck of carbon dust is not a nuisance. It is a structural failure waiting to happen.

This is why the choice of metal in a hot zone is not merely a specification. It is a philosophy of risk management.

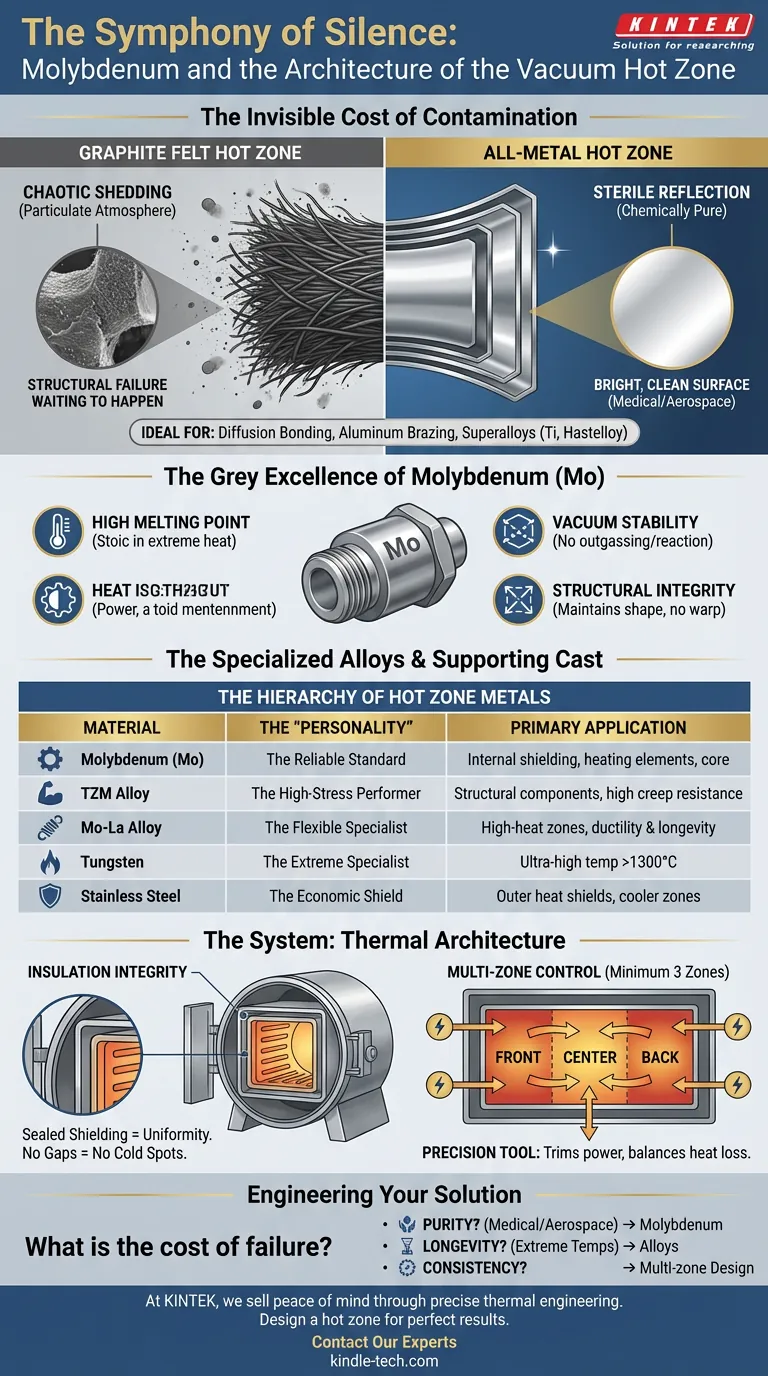

The Argument for All-Metal Environments

Most insulation works by trapping heat. Graphite felt, for example, is excellent at this. But graphite has a personality flaw: it sheds.

In a vacuum, that shedding creates a particulate atmosphere. For standard heat treating, this is acceptable. But for sensitive processes—diffusion bonding, aluminum brazing, or working with superalloys (Titanium, Hastelloy)—it is catastrophic.

An all-metal hot zone is the engineering answer to this problem.

It replaces the chaotic shedding of graphite with the sterile reflection of polished metal. It ensures that the parts coming out are as chemically pure as the materials that went in. In the medical sector, where a bright, clean surface is non-negotiable, this purity is the product.

The Grey Excellence of Molybdenum

If the hot zone is a stage, Molybdenum (Mo) is the lead actor.

It is the industry standard not because it is the cheapest, but because it is the most predictable. Molybdenum possesses a unique "engineer’s temperament":

- High Melting Point: It remains stoic in the face of extreme heat.

- Vacuum Stability: It does not outgas or react unpredictably.

- Structural Integrity: It maintains its shape when other metals would sag or warp.

However, even the best actors need support.

The Specialized Alloys: TZM and Mo-La

Pure Molybdenum has limits. Under specific high-stress conditions, it can suffer from recrystallization—essentially, the metal's grain structure changes, making it brittle.

To solve this, metallurgists introduce "impurities" on purpose to create strength:

- TZM Alloy (Titanium-Zirconium-Molybdenum): By adding trace amounts of Ti and Zr, we significantly boost the recrystallization temperature and creep resistance. It is Molybdenum, but tougher.

- Molybdenum-Lanthanum (Mo-La): This "doped" alloy offers superior ductility after high-temperature exposure.

The Supporting Cast

- Tungsten: Used when the heat goes beyond Molybdenum’s comfort zone (up to 2800°C+). It is the heavy lifter.

- Stainless Steel: Used for the outer layers where temperatures drop. It provides cost-effective structural support where the exotic properties of Mo aren't required.

The Hierarchy of Hot Zone Metals

Here is how engineers select the right tool for the thermal job:

| Material | The "Personality" | Primary Application |

|---|---|---|

| Molybdenum (Mo) | The Reliable Standard | Internal shielding, heating elements, core components. |

| TZM Alloy | The High-Stress Performer | Structural components requiring high creep resistance. |

| Mo-La Alloy | The Flexible Specialist | High-heat zones requiring ductility and longevity. |

| Tungsten | The Extreme Specialist | Ultra-high temperature zones exceeding 1300°C. |

| Stainless Steel | The Economic Shield | Outer heat shield layers (cooler zones). |

The System: It’s Not Just the Metal

Having the right materials is only half the equation. You can build a house out of marble, but if the walls have gaps, you will still freeze.

The performance of a vacuum furnace relies on Thermal Architecture.

The insulation integrity

Temperature uniformity is dictated by how well the shielding is assembled. Gaps in the insulation package—particularly around gas flow ports—create thermal leaks. These leaks lead to cold spots. In diffusion bonding, a cold spot means a bond that never formed.

Multi-zone control

A single heating source is rarely enough for precision work.

A robust design requires a minimum of three distinct heating zones. This allows the system to "trim" the power input, balancing the heat loss at the front and back of the furnace against the center. It turns a blunt instrument into a precision tool.

Engineering Your Solution

The choice between graphite and metal, or Pure Mo and TZM, comes down to one question: What is the cost of failure?

- If you need purity (Medical/Aerospace), you need Molybdenum.

- If you need longevity at extreme temps, you need Alloys.

- If you need consistency, you need a multi-zone design.

At KINTEK, we don't just sell equipment; we sell the peace of mind that comes from precise thermal engineering. We understand the nuance of superalloy processing and the strict demands of the medical industry.

Let us help you design a hot zone that disappears into the background, leaving you with nothing but perfect results.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

Related Articles

- How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production

- Your Furnace Hit the Right Temperature. So Why Are Your Parts Failing?

- Molybdenum Vacuum Furnace: High-Temperature Sintering and Advanced Applications

- Your Vacuum Furnace Hits the Right Temperature, But Your Process Still Fails. Here’s Why.

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries