What is infrared tablet press

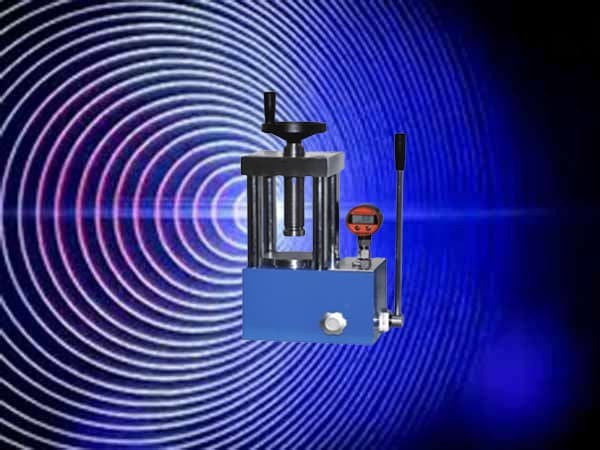

Infrared tablet press is a compact, labor-saving, convenient and specialized manual hydraulic machine designed specifically for the preparation of powder specimens for infrared spectrometers.

A spectrometer is an instrument that is used to measure properties of light over a specific portion of the electromagnetic spectrum, and the application of an infrared spectrometer led to the development of the supporting facilities infrared tablet press. The infrared spectrometer is used to identify functional groups in molecules, which in turn allows for the characterization of organic compounds. The infrared tablet press is a manual hydraulic type press that is used to produce tablets from a powder or granular material.

The infrared tablet press form Kindle Tech is designed for use in industrial, research, and teaching applications. The press has a compact footprint and can be easily integrated into a variety of systems. The press can be operated in both manual and automatic mode.

How to use

The use of an infrared tablet press is very simple. First, a small quantity of sample powder is placed onto the upper die of the press. Then, the operator uses the hydraulically operated handle to slowly apply pressure to the powder. As the pressure increases, the powder is compacted into a harder and denser form. Finally, when the desired tablet density is reached, the operator releases the pressure and removes the tablet from the die. The advantage of using an infrared tablet press for sample preparation is that it allows for great control over the density of the tablet. This is important because the density of the tablet will directly affect the quality of the infrared spectrum. In addition, the tablet press is very easy to use and can be easily operated by even inexperienced users.

Principle

The infrared tablet press is designed according to the hydraulic principle that the force acting on the two pistons is proportional to the cross-sectional area of the two pistons. This machine is very efficient in terms of energy consumption and its working process is very simple too. The machine is designed in such a way that the force required to operate it is very less as compared to other machines of its kind.

When the oil drain valve is tightened, the handle is repeatedly moved to make the small plunger reciprocate, and the sucked oil is pressed into the oil cavity of the large piston, thereby pushing the large piston to rise. When the large piston is blocked from rising, the pressure gauge displays the pressure value.

Application

The infrared tablet press is a mini-type pressure testing machine, a small, labor-saving, convenient, and strong manual hydraulic infrared tableting machine. It is specially designed for the preparation of powder samples by infrared spectrometers. The whole machine is made of aluminum alloy and stainless steel, which are corrosion-resistant and wear-resistant. The working table is equipped with four clamping rods, which can be adjusted freely according to the size of the mold.

The infrared tablet press can be used for other pressure tests, with pressure measurement indication function, especially suitable for supporting various Fourier transform infrared spectrometers. The tablet press can be used to test the pressure of various materials, and can also be used to calibrate the pressure measuring instruments.

Common problem

When the formulation contains crystalline and semi-crystalline resins (including curing agents), if the temperature of the mixing section exceeds 70℃, the discharge will be very viscous and cannot be pressed into tablets, because the crystalline and semi-crystalline resins have melted. When the resin is cooled to recrystallize (more than 10min), the amorphous resin has already cooled, and the material can no longer pass through the infrared tablet press.

As with any type of grinding or pulverizing, if the UV-curable powder coating contains semi-crystalline resin or the glass transition temperature in the formulation system is lower than 20℃, the material must be cooled before grinding and pulverizing by the infrared tablet machine. When grinding, the outlet temperature should not exceed 30℃. This is to prevent the UV-curable powder coating from becoming too viscous and difficult to work with.

Related Products

- Manual Lab Heat Press

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

Related Articles

- Applications and Importance of Hydraulic Press in Laboratories

- The Science Behind Hydraulic Presses and Their Applications

- Comprehensive Guide on Pellet Press Dies and Their Applications

- Comprehensive Guide to Hydraulic Hot Press: Function, Features and Applications

- Understanding Hydraulic Pellet Press: Working Mechanism and Applications