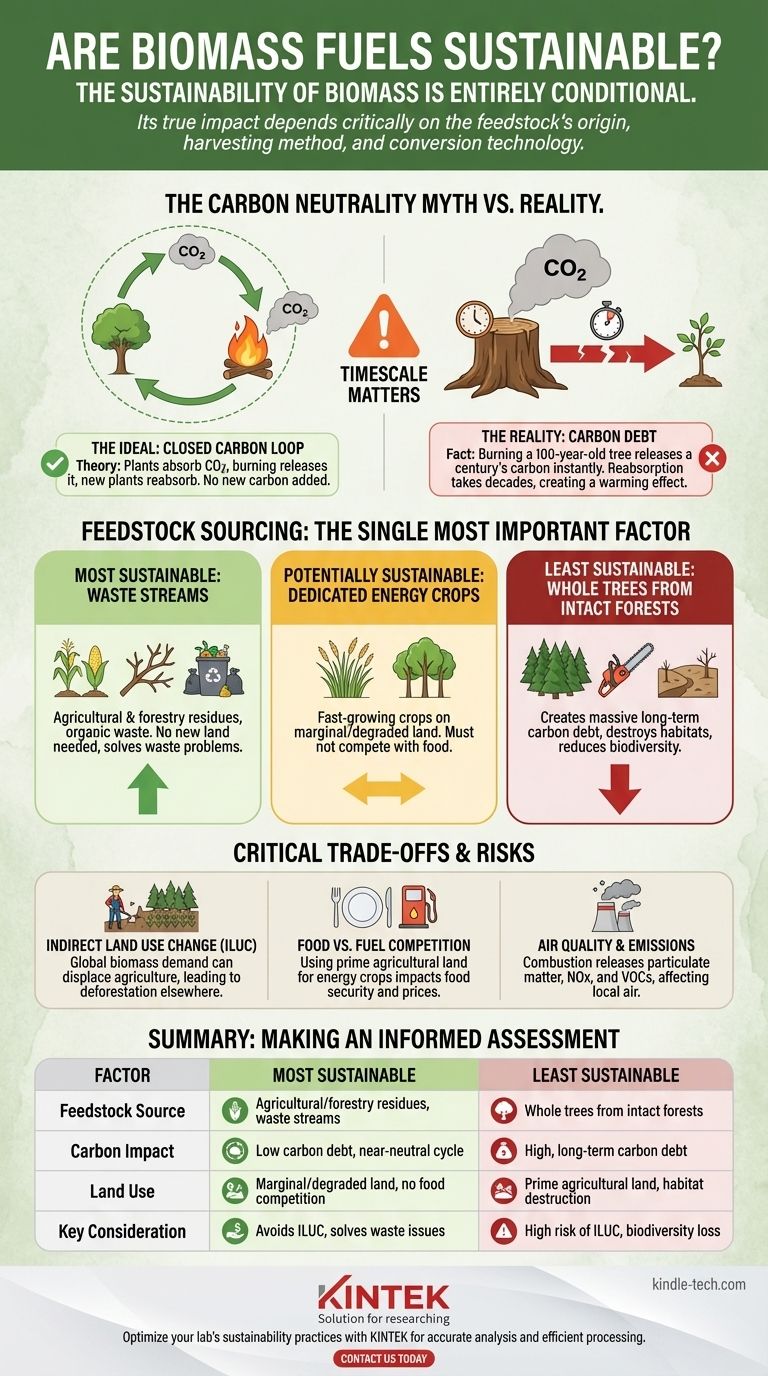

The sustainability of biomass is entirely conditional. While often classified as a renewable energy source, its true environmental impact depends critically on the feedstock's origin, how it is harvested, and the technology used for its conversion. True sustainability is achieved only under specific, carefully managed circumstances and is never a guaranteed property of the fuel itself.

Biomass is not inherently sustainable or unsustainable. Its sustainability is a direct result of its lifecycle management—from the sourcing of raw materials to energy conversion—making the choice of feedstock and process the determining factors.

The Carbon Neutrality Myth vs. Reality

To properly evaluate biomass, you must first understand the concept of carbon neutrality. This is the central claim for its sustainability, but the reality is far more complex.

The Ideal: A Closed Carbon Loop

The theoretical promise of biomass is a closed carbon loop. As plants grow, they absorb carbon dioxide (CO2) from the atmosphere. When this biomass is burned for energy, it releases that same CO2 back into the atmosphere, where it can be reabsorbed by new plant growth.

In this perfect model, no new carbon is added to the atmosphere, making the process "carbon neutral" in contrast to fossil fuels, which release ancient, long-sequestered carbon.

The Problem: The "Carbon Debt"

The ideal model breaks down when you consider timescale. Burning a 100-year-old tree releases a century's worth of stored carbon instantly. It will take another 100 years for a newly planted tree to reabsorb that same amount of carbon.

This time lag creates a "carbon debt." For decades or even centuries, that excess CO2 remains in the atmosphere, contributing to warming. The planet does not distinguish between a CO2 molecule from a lump of coal and one from a tree trunk; its warming effect is the same.

Feedstock Sourcing: The Single Most Important Factor

The source of the raw material, or feedstock, is the most critical variable determining whether a biomass fuel is truly sustainable or if it creates a significant carbon debt.

The Most Sustainable: Waste Streams

Biomass derived from waste products is generally the most sustainable option. This includes agricultural residues (like corn stalks), forestry residues (like branches and treetops left after logging), and the organic portion of municipal solid waste.

These sources are highly beneficial because they do not require new land to be cultivated, avoiding displacement of food crops or natural habitats. Using them for energy also solves a waste disposal problem, often avoiding methane emissions from decomposition in a landfill.

The Potentially Sustainable: Dedicated Energy Crops

Dedicated energy crops, such as fast-growing grasses (switchgrass, miscanthus) or trees (poplar, willow), can be a sustainable feedstock under the right conditions.

The key is growing them on marginal or degraded land that is not suitable for food production. This approach can improve soil health and create a new resource without competing with the food supply or clearing natural ecosystems.

The Least Sustainable: Whole Trees from Intact Forests

Using whole trees from existing, especially old-growth or primary, forests is the least sustainable and most environmentally damaging practice.

This feedstock creates a massive and long-term carbon debt, destroys critical habitats, reduces biodiversity, and disrupts vital ecosystem services like water filtration.

Understanding the Critical Trade-offs

Even with careful sourcing, biomass energy involves significant risks and trade-offs that are not present with non-combustion renewables like solar or wind.

The Danger of Indirect Land Use Change (ILUC)

Even if energy crops are grown on previously unused land, they can cause indirect land use change (ILUC). If a global demand for biomass drives up the price of agricultural land, a farmer elsewhere might be incentivized to clear a forest to plant food crops.

This "leakage" effect means that even a seemingly sustainable biomass project can be indirectly responsible for deforestation and carbon emissions elsewhere in the world.

Competition with Food Production

The "food vs. fuel" debate is a major ethical and economic concern. Using prime agricultural land to grow energy crops can reduce the global food supply, potentially leading to higher food prices and impacting food security, particularly in developing nations.

Air Quality and Emissions

Unlike wind or solar, biomass is a combustion-based energy source. Burning biomass releases air pollutants, including particulate matter (PM2.5), nitrogen oxides (NOx), and volatile organic compounds (VOCs).

While modern facilities use control technologies to minimize these emissions, they still have a tangible impact on local and regional air quality, which must be weighed against the benefits.

Making an Informed Assessment

Evaluating biomass requires moving beyond simple labels and scrutinizing the entire supply chain. Use the following criteria to guide your decision-making.

- If your primary focus is rapid, verifiable carbon reduction: Prioritize biomass derived from agricultural, forestry, or municipal waste streams, as they avoid land-use change and carry the lowest carbon debt.

- If your primary focus is developing a local, circular economy: Favor dedicated energy crops grown on certified marginal or degraded land that is unsuitable for food production, coupled with local processing and use.

- If your primary focus is risk mitigation: Scrutinize any biomass sourced from whole trees or feedstocks that could displace food crops, as these carry the highest risk of negative carbon, land-use, and social impacts.

Your ability to distinguish between a truly sustainable resource and a detrimental one lies in critically evaluating its entire lifecycle.

Summary Table:

| Factor | Most Sustainable | Least Sustainable |

|---|---|---|

| Feedstock Source | Agricultural/forestry residues, waste streams | Whole trees from intact forests |

| Carbon Impact | Low carbon debt, near-neutral cycle | High, long-term carbon debt |

| Land Use | Marginal/degraded land, no food competition | Prime agricultural land, habitat destruction |

| Key Consideration | Avoids ILUC, solves waste issues | High risk of ILUC, biodiversity loss |

Optimize your lab's sustainability practices with KINTEK.

As you navigate the complexities of biomass and other energy sources, having the right equipment is crucial for accurate analysis and efficient processing. KINTEK specializes in high-quality lab equipment and consumables, supporting researchers and industries in making data-driven, sustainable decisions.

Whether you're analyzing feedstock composition, testing emissions, or developing new bioenergy processes, our reliable tools help you achieve precise and reproducible results. Contact us today to discuss how our solutions can enhance your laboratory's capabilities and contribute to your sustainability goals.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Laboratory Hybrid Tissue Grinding Mill

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

People Also Ask

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- Which features of vacuum hot pressing equipment are utilized by the dual-step vacuum hot press process? Optimize AlMgTi

- Why is a vacuum hot-pressing furnace preferred for C_fiber/Si3N4 composites? Achieve High Density & Fiber Protection

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use