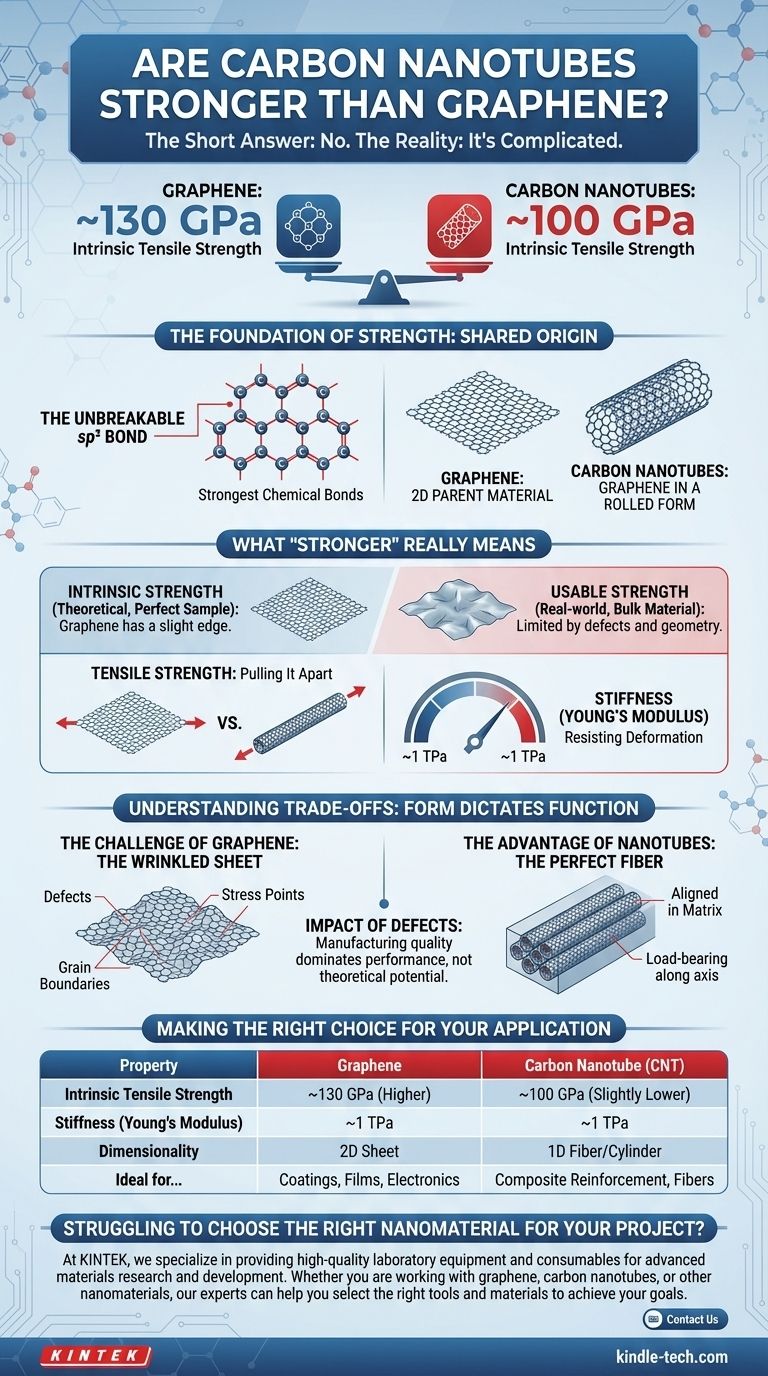

The short answer is no. Graphene is theoretically the strongest material ever measured, with a tensile strength of 130 gigapascals (GPa). However, this simple answer masks a much more complex and important reality. For practical engineering purposes, the "stronger" material depends entirely on the application and form factor.

While graphene holds the title for intrinsic strength in a perfect, two-dimensional plane, carbon nanotubes often deliver more effective and usable strength in real-world applications due to their one-dimensional, fiber-like structure.

The Foundation of Strength: A Shared Origin

Both graphene and carbon nanotubes (CNTs) derive their incredible properties from the exact same source: the arrangement of their carbon atoms.

The Unbreakable sp² Bond

At the atomic level, the strength of both materials comes from sp² hybridized carbon-carbon bonds. These are some of the strongest chemical bonds known, forming a hexagonal lattice that is exceptionally resistant to being pulled apart.

Graphene: The 2D Parent Material

Graphene is a single, flat sheet of these carbon atoms arranged in a honeycomb pattern. It is the fundamental building block. Its theoretical strength has been measured at ~130 GPa, making it the strongest material ever tested.

Carbon Nanotubes: Graphene in a Rolled Form

A single-walled carbon nanotube is best understood as a sheet of graphene that has been seamlessly rolled into a cylinder. Because it is made of the exact same atomic structure, its intrinsic strength is also exceptionally high, with theoretical values often cited around 100 GPa.

What "Stronger" Really Means

The term "stronger" can be misleading. In materials science, we must be specific about the properties we are measuring, as this context is crucial for any real-world application.

Intrinsic Strength vs. Usable Strength

Intrinsic strength refers to the theoretical strength of a perfect, defect-free sample. This is where graphene has a slight edge. Usable strength, however, is the strength you can actually achieve when you make a bulk material or component, which is always limited by defects and geometry.

Tensile Strength: Pulling It Apart

Tensile strength measures a material's resistance to being stretched before it breaks. While graphene's in-plane strength is the highest, it's difficult to pull on a two-dimensional sheet uniformly to take advantage of it. A CNT, being a one-dimensional fiber, is naturally suited to bearing a load along its length.

Stiffness (Young's Modulus): Resisting Deformation

Both materials are also incredibly stiff, with a Young's Modulus of approximately 1 Terapascal (TPa). This means it takes an enormous amount of force to elastically deform them, a property they share due to their common sp² bonding.

Understanding the Trade-offs: Form Dictates Function

The most significant difference between the two materials is not their atomic bonds, but their dimensionality. This is the factor that most often determines which one is the right choice for a specific engineering challenge.

The Challenge of Graphene: The Wrinkled Sheet

Graphene's primary challenge is its 2D nature. Producing large, defect-free sheets is extremely difficult. Real-world graphene is often plagued by defects, grain boundaries, and wrinkles, all of which act as stress concentration points and drastically reduce its effective strength from the theoretical maximum.

The Advantage of Nanotubes: The Perfect Fiber

The 1D, fiber-like structure of CNTs makes them almost perfect reinforcing agents. They can be aligned within a polymer or metal matrix to create a composite material. In this form, their exceptional tensile strength can be leveraged directly along their axis to carry a load, a task they are geometrically better suited for than a 2D sheet.

The Impact of Defects

For both materials, defects are the great equalizer. A high-quality, nearly perfect carbon nanotube will be much stronger in practice than a large-area graphene sheet with many defects and grain boundaries. The performance of any final product is dominated by manufacturing quality, not theoretical potential.

Making the Right Choice for Your Application

Choosing between these materials depends entirely on the engineering goal. The question should not be "Which is stronger?" but "Which geometry is right for my problem?"

- If your primary focus is creating ultra-strong, lightweight composites: Carbon nanotubes are often the more practical choice, as their fiber-like shape is ideal for reinforcing a matrix material.

- If your primary focus is on transparent conductive films or barrier coatings: Graphene's 2D sheet-like nature makes it the superior material, where its in-plane properties can be fully utilized.

- If your primary focus is fundamental research into the limits of material strength: Graphene remains the benchmark, as it represents the theoretical upper limit for sp²-bonded carbon.

Ultimately, the debate over strength is less about a theoretical contest and more about selecting the right geometry for the job.

Summary Table:

| Property | Graphene | Carbon Nanotube (CNT) |

|---|---|---|

| Intrinsic Tensile Strength | ~130 GPa (Higher) | ~100 GPa (Slightly Lower) |

| Stiffness (Young's Modulus) | ~1 TPa | ~1 TPa |

| Dimensionality | 2D Sheet | 1D Fiber/Cylinder |

| Ideal for... | Coatings, Films, Electronics | Composite Reinforcement, Fibers |

Struggling to choose the right nanomaterial for your project?

At KINTEK, we specialize in providing high-quality laboratory equipment and consumables for advanced materials research and development. Whether you are working with graphene, carbon nanotubes, or other nanomaterials, our experts can help you select the right tools and materials to achieve your goals.

Contact us today to discuss your specific application needs and discover how KINTEK can support your innovation in materials science. Get in touch via our contact form – let's build the future of materials together.

Visual Guide

Related Products

- Boron Nitride (BN) Ceramic Tube

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Vertical High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What are the disadvantages of brazing? Understanding the key limitations and trade-offs.

- What is a ceramic tube? A Guide to Extreme Environment Performance

- What are ceramic tubes used for? Essential Components for Extreme Heat & Electrical Insulation

- Why is Boron Nitride used in RRDE? Enhance Precision with Superior Insulating and Protective Material

- What are the strengths of brazing? Achieve Strong, Clean, and Precise Metal Joining