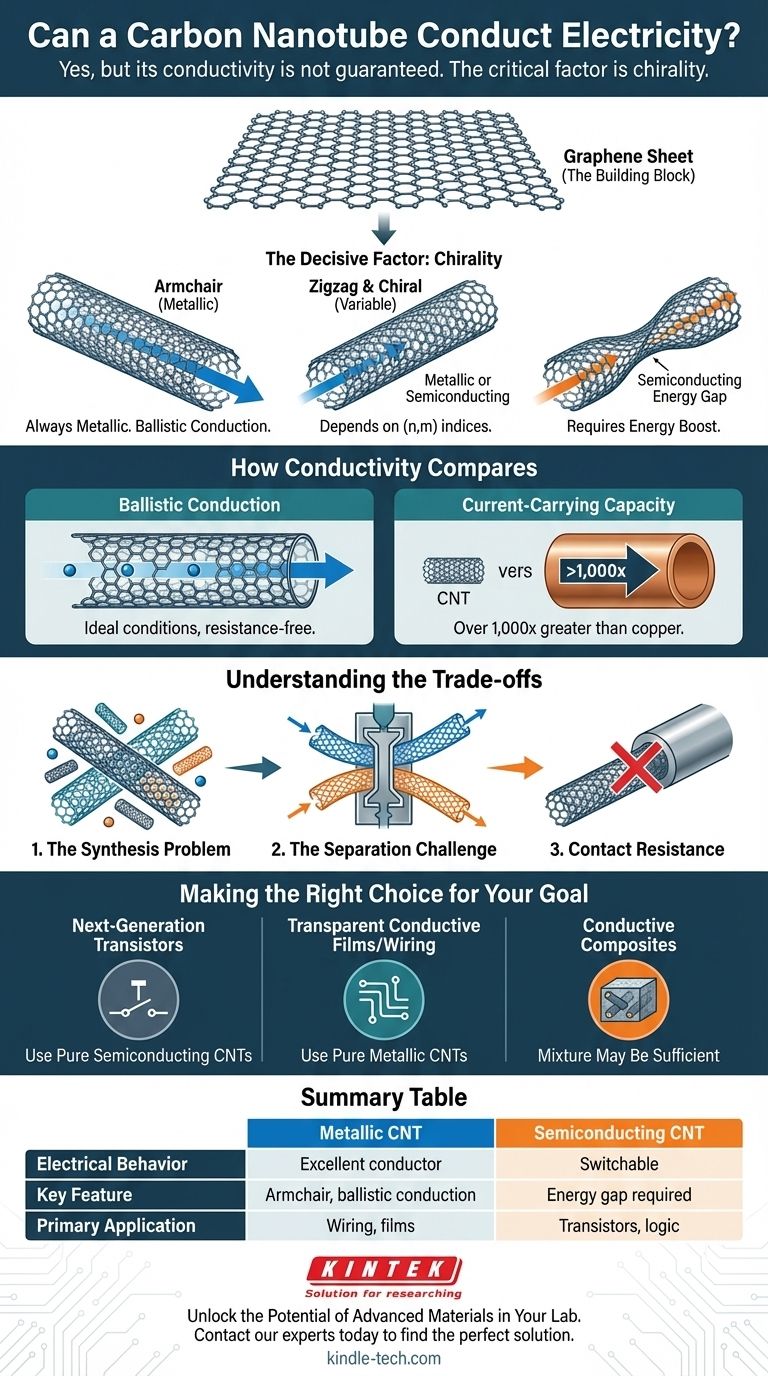

Yes, but its conductivity is not guaranteed. A carbon nanotube (CNT) can be an excellent electrical conductor—often better than copper—or it can be a semiconductor, similar to silicon. This critical difference is not determined by the material itself, but by the specific atomic geometry of the individual nanotube.

The single most important factor determining a carbon nanotube's electrical properties is its chirality—the angle at which the seamless graphite sheet is "rolled" to form the tube. This structural twist dictates whether electrons can flow freely (metallic) or require an energy boost to flow (semiconducting).

From Graphene Sheet to Nanotube

The Building Block: Graphene

To understand a nanotube, you must first understand graphene. Graphene is a single, one-atom-thick sheet of carbon atoms arranged in a honeycomb lattice. It is a highly conductive two-dimensional material.

A carbon nanotube is simply a sheet of graphene rolled into a seamless cylinder. The way you roll this sheet fundamentally defines the resulting tube's properties.

The Decisive Factor: Chirality

The term chirality refers to the angle and diameter of the rolled graphene sheet. This geometry is specified by a pair of indices (n,m) that describe how the sheet is wrapped.

Based on these indices, CNTs fall into three main categories, each with distinct electrical behaviors.

Armchair: The Perfect Conductor

When the graphene sheet is rolled straight, creating a pattern that resembles the armrests of a chair along the tube's circumference, it is called an armchair nanotube.

Armchair nanotubes are always metallic. They are exceptional conductors because their atomic structure provides a direct, unobstructed path for electrons to flow.

Zigzag and Chiral: The Variable Tubes

If the sheet is rolled at any other angle, it forms either a zigzag or chiral (meaning "twisted") nanotube.

These types can be either metallic or semiconducting, depending on their precise geometry. A simple rule of thumb exists: if the difference in their (n,m) indices is a multiple of three, the tube behaves like a metal. If not, it behaves like a semiconductor.

How Conductivity Compares

Ballistic Conduction

Under ideal conditions, electrons can pass through short carbon nanotubes without scattering off atoms, a phenomenon known as ballistic conduction.

This allows for nearly resistance-free electron flow, making CNTs theoretically superior to traditional conductors like copper, where electrons constantly collide with the material's lattice, generating heat and energy loss.

Current-Carrying Capacity

Carbon nanotubes also possess an incredibly high current-carrying capacity (ampacity). They can sustain electrical current densities more than 1,000 times greater than that of copper without melting or degrading.

Understanding the Trade-offs

The remarkable properties of CNTs are well-established in the lab, but their practical, large-scale application faces significant hurdles.

The Synthesis Problem

Current synthesis methods, such as chemical vapor deposition, produce a mixture of nanotubes. The resulting material is a random assortment of metallic and semiconducting tubes with various diameters and chiralities.

For most electronic applications, this mixture is unusable. A wire made of mixed tubes has inconsistent properties, and a transistor built from it would be unreliable.

The Separation Challenge

Because synthesis creates a mix, researchers must perform post-processing to separate the metallic tubes from the semiconducting ones.

This sorting process is complex, expensive, and remains a major bottleneck to the commercialization of CNT-based electronics.

Contact Resistance

Creating a clean, low-resistance electrical connection between a microscopic nanotube and a macroscopic metal wire (like a circuit board trace) is extremely difficult.

Poor contacts can introduce significant resistance, negating the inherent advantages of the nanotube's low internal resistance.

Making the Right Choice for Your Goal

The "right" kind of carbon nanotube depends entirely on the intended application.

- If your primary focus is next-generation transistors: You must isolate purely semiconducting CNTs, which can be switched on and off to represent the 1s and 0s of digital logic.

- If your primary focus is transparent conductive films or wiring: You need to isolate purely metallic CNTs to create low-resistance, high-ampacity electrical pathways.

- If your primary focus is creating conductive composites: A mixture of CNT types may be sufficient to add electrical conductivity and mechanical strength to a bulk material like a polymer.

Harnessing the full potential of carbon nanotubes depends on our ability to control their structure at the atomic level.

Summary Table:

| Property | Metallic CNT | Semiconducting CNT |

|---|---|---|

| Electrical Behavior | Excellent conductor (like copper) | Can be switched on/off (like silicon) |

| Key Feature | Armchair structure; ballistic conduction | Requires energy gap for conduction |

| Primary Application | Wiring, transparent conductive films | Transistors, digital logic |

Unlock the Potential of Advanced Materials in Your Lab

Harnessing the unique properties of materials like carbon nanotubes requires precision equipment. Whether you are developing next-generation electronics or conductive composites, KINTEK provides the reliable lab equipment and consumables you need to innovate with confidence.

Let's achieve your research goals together. Contact our experts today to find the perfect solution for your laboratory.

Visual Guide

Related Products

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Electrode Polishing Material for Electrochemical Experiments

- Custom PTFE Teflon Parts Manufacturer for PTFE Containers

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- What are the categories of carbon nanotubes? Understand SWCNT vs. MWCNT for Your Application

- Which parameters affect sputter yield using an ion beam? Master Ion Energy, Mass, Angle & Material Properties

- What is the synthesis process of graphene? A Guide to Top-Down and Bottom-Up Methods

- Why is coating thickness important? Achieve Optimal Performance and Cost Control

- What is sputter coating SEM? Achieve Clear, High-Resolution Imaging for Non-Conductive Samples

- What are the applications of sputtering deposition? Achieve Superior Thin Films for Electronics, Optics & Tools

- Which is the chemical exfoliation method for graphene synthesis? A Top-Down Approach for Mass Production

- Which is better CVD or HPHT lab-grown diamonds? Focus on Quality, Not the Method.