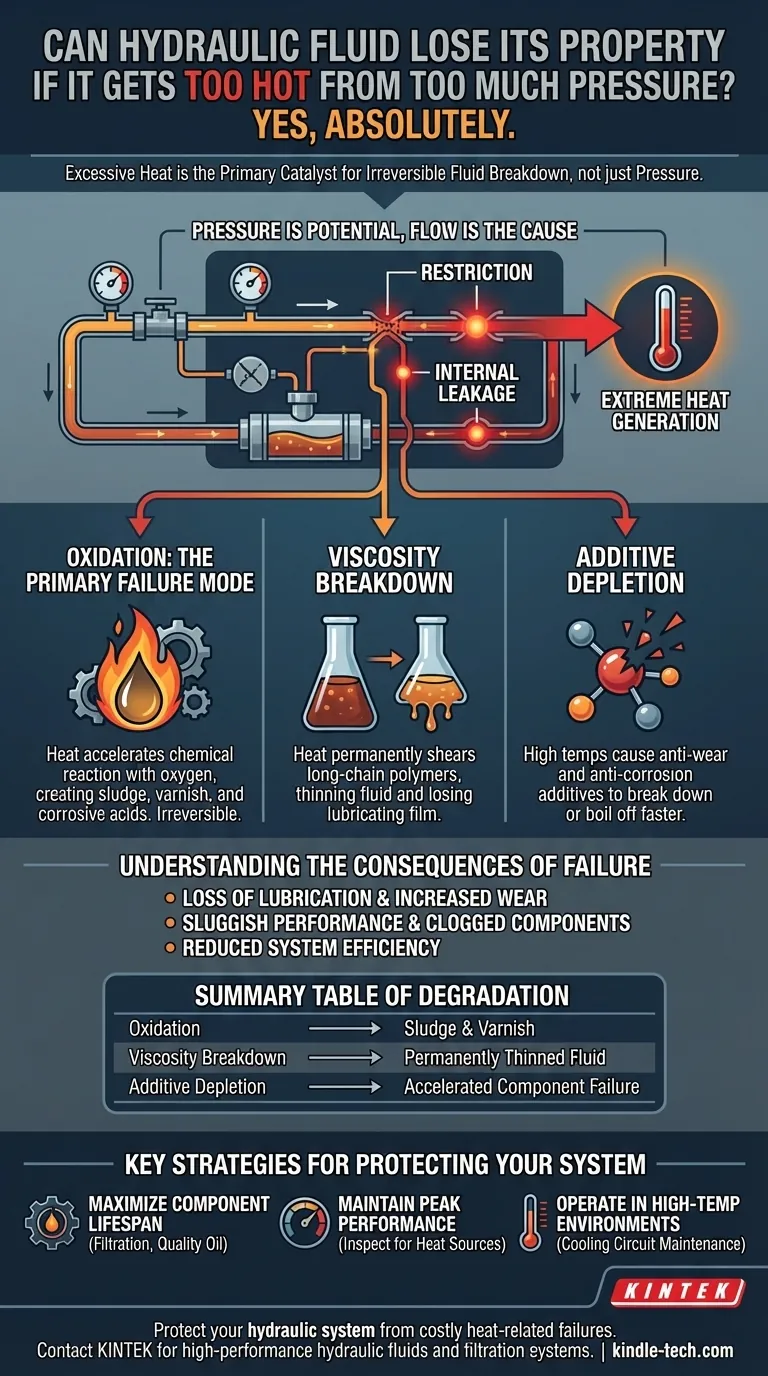

Yes, absolutely. A hydraulic fluid will permanently lose its essential properties if it gets too hot. While high pressure is a factor, it is the excessive heat—often generated by forcing fluid to move under that high pressure—that acts as the primary catalyst for irreversible chemical and physical breakdown of the oil.

The core issue is that high system pressure creates the conditions for extreme heat generation. It is this heat, not the pressure itself, that triggers oxidation and viscosity breakdown, permanently degrading the fluid and leading to component wear and system failure.

The Real Relationship Between Pressure and Heat

To protect a hydraulic system, it's critical to understand that pressure is the potential, but heat is the actual agent of destruction. Heat is not a byproduct of static pressure, but of fluid in motion against resistance.

Pressure is Potential, Flow is the Cause

Think of system pressure as stored energy. This energy is converted into heat when the fluid is forced to flow through restrictions or when it shears internally due to inefficiency. The higher the pressure drop across a restriction, the more energy is converted into heat.

Where Heat is Actually Generated

The most common sources of heat in a hydraulic circuit are points of significant pressure drop. This includes relief valves cycling unnecessarily, throttling or flow control valves, and—most critically—internal leakage past worn seals in pumps, motors, and cylinders.

The Vicious Cycle of Heat

As the fluid gets hotter, its viscosity (thickness) decreases. This thinner oil leaks more easily past internal seals, which in turn generates even more heat. This creates a feedback loop of escalating temperatures and accelerating fluid degradation.

How Excessive Heat Destroys Hydraulic Fluid

Temperatures above 180°F (82°C) begin to seriously accelerate the aging process of most mineral-based hydraulic oils. This degradation happens in three primary ways.

Oxidation: The Primary Failure Mode

Oxidation is a chemical reaction between the oil's hydrocarbon base and oxygen, massively accelerated by heat. This process "burns" the oil, creating byproducts like sludge, varnish, and corrosive acids that are completely irreversible. Varnish can cause valves to stick, while sludge clogs filters and passages.

Viscosity Breakdown

Hydraulic fluid is engineered to maintain a stable viscosity across a range of temperatures. Excessive heat permanently shears the long-chain polymer molecules (Viscosity Index Improvers) that provide this stability. The result is a fluid that is permanently thinner and can no longer create an adequate lubricating film between moving parts.

Additive Depletion

Modern hydraulic fluids contain a sophisticated package of additives for anti-wear, anti-foaming, and corrosion inhibition. High temperatures cause these additives to break down or "boil off" much faster than intended, leaving the base oil without its crucial protective qualities.

Understanding the Consequences of Failure

Operating with degraded fluid is not a sustainable condition. It actively damages the expensive components of your hydraulic system, leading to predictable and costly failures.

Loss of Lubrication and Increased Wear

When viscosity and anti-wear additives are compromised, the fluid film protecting metal surfaces becomes insufficient. This leads to direct metal-on-metal contact, causing accelerated wear in pumps, motors, and actuators, which generates metallic contaminants and further accelerates system destruction.

Sluggish Performance and Clogged Components

The sludge and varnish created by oxidation coat internal surfaces. This is most noticeable when it causes control valves to stick or respond slowly, leading to erratic machine operation. These deposits also clog filters and reduce the system's ability to dissipate heat.

Reduced System Efficiency

As fluid thins and internal leakage increases, the pump must work harder and consume more energy to perform the same amount of work. This wasted energy is converted directly into more heat, worsening the root problem and increasing operating costs.

Key Strategies for Protecting Your System

Preventing heat-related fluid degradation is the single most effective maintenance strategy for ensuring hydraulic system reliability and longevity. Your approach should be proactive, not reactive.

- If your primary focus is maximizing component lifespan: Maintain meticulous fluid cleanliness through a strict filtration schedule and use a high-quality oil with a robust additive package designed for your operating conditions.

- If your primary focus is maintaining peak system performance: Regularly inspect the system for sources of heat, such as a relief valve set too low or worn components causing excessive internal leakage, and address them immediately.

- If your primary focus is operating in high-temperature environments: Ensure the system's cooling circuit (heat exchanger, fans, reservoir) is clean, functional, and properly sized for the application's thermal load.

Ultimately, managing heat is the most critical factor in controlling the health and longevity of any hydraulic system.

Summary Table:

| Aspect of Degradation | Key Consequence |

|---|---|

| Oxidation | Creates sludge and varnish, leading to clogged components and valve sticking. |

| Viscosity Breakdown | Permanently thins the fluid, reducing lubrication and increasing wear. |

| Additive Depletion | Removes anti-wear and anti-corrosion protection, accelerating component failure. |

Protect your hydraulic system from costly heat-related failures. KINTEK specializes in lab equipment and consumables, including high-performance hydraulic fluids and filtration systems designed to withstand extreme conditions. Our solutions help maintain fluid integrity, reduce wear, and extend the life of your critical components. Contact us today to find the right fluid and maintenance strategy for your laboratory's hydraulic needs!

Visual Guide

Related Products

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- How does a laboratory hydraulic hot press ensure the quality of PHBV/natural fiber composites? Expert Guide

- Why is a hydraulic press used for pre-deformation treatment? Enhance Coating Hardness & Thermal Stability

- What role does a laboratory hydraulic hot press play in rice husk-based composite boards? Achieve Structural Density

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What technical conditions does a heated hydraulic press provide for PEO batteries? Optimize Solid-State Interfaces