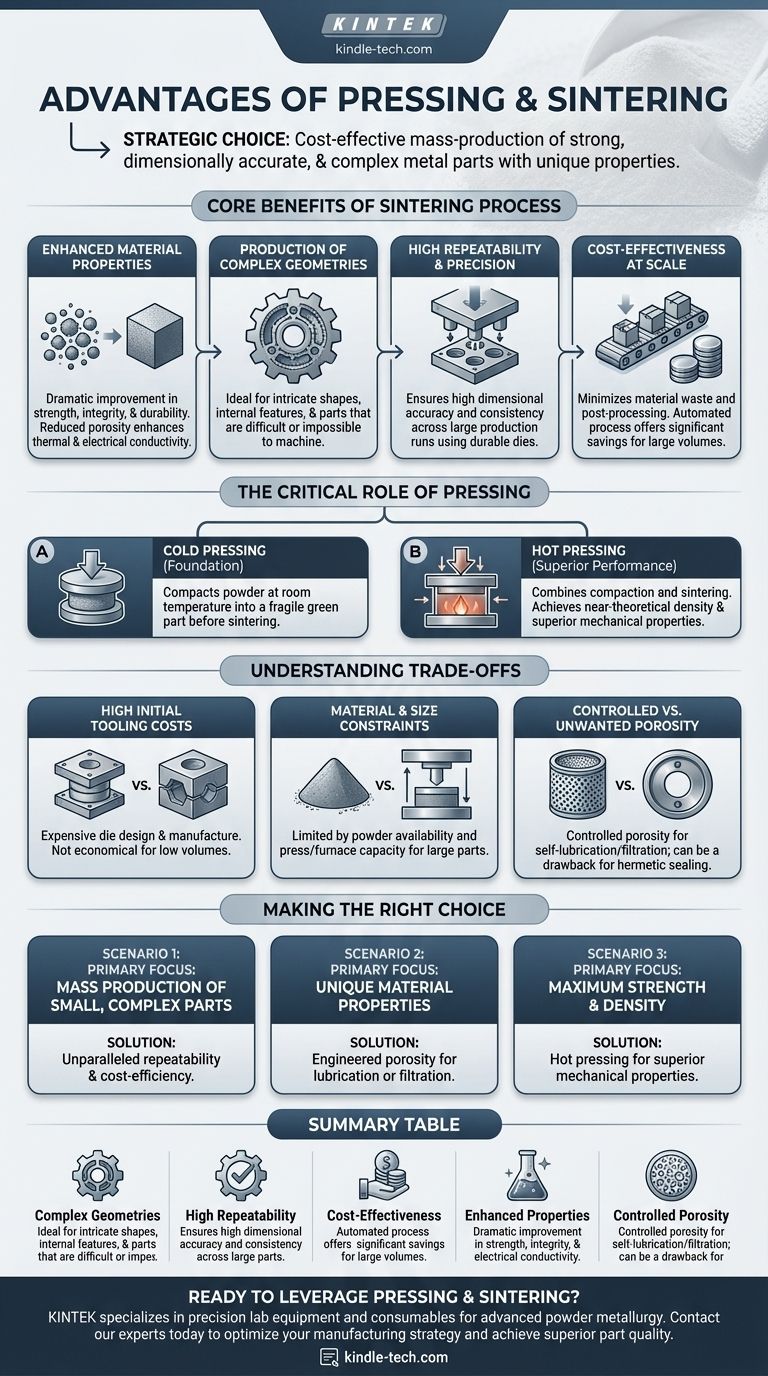

The primary advantages of pressing and sintering are the ability to cost-effectively mass-produce strong, dimensionally accurate, and complex metal parts. This powder metallurgy process excels at creating components with unique material properties and geometries that are often difficult or impossible to achieve through traditional machining or casting.

Pressing and sintering is not just a manufacturing method; it's a strategic choice for achieving a unique combination of geometric complexity, material performance, and high-volume economic efficiency that other processes cannot easily match.

Core Benefits of the Sintering Process

Sintering is the heart of the process, where compacted powder is heated to below its melting point. This thermal energy fuses the particles together, fundamentally transforming the material's structure and properties.

Enhanced Material Properties

Sintering dramatically improves the physical characteristics of the final part. The process reduces the empty space, or porosity, between the initial powder particles.

This densification leads directly to increased strength, integrity, and durability. Furthermore, it enhances both thermal and electrical conductivity as the particle-to-particle bonds become more robust.

Production of Complex Geometries

Pressing powder into a die allows for the creation of intricate shapes, including internal cavities or features that are non-machinable.

This capability makes it an ideal choice for parts that would otherwise require multiple components or extensive, costly machining operations.

High Repeatability and Precision

The use of durable, precision-machined dies for the pressing stage ensures that every part produced is nearly identical.

This process delivers high dimensional accuracy and repeatability across massive production runs, which is critical for components used in complex assemblies.

Cost-Effectiveness at Scale

While initial tooling costs can be significant, the process is highly automated and produces parts with a net shape that requires little to no finishing.

This minimizes material waste and post-processing, making it an extremely cost-effective method for large-volume production.

The Critical Role of Pressing

The "pressing" stage is what gives the part its initial shape and density before sintering can lock it in. The specific method of pressing has a significant impact on the final outcome.

Cold Pressing: The Foundation

In the most common method, powder is compacted at room temperature in a die to form a "green compact." This green part is fragile but holds its shape well enough to be transferred to the sintering furnace.

Hot Pressing: Superior Density and Performance

Hot pressing combines the compaction and sintering steps into a single operation. Pressure is applied to the powder while it is at an elevated temperature.

This method requires significantly less pressure than cold pressing and reduces the required sintering time and temperature. The result is a component with near-theoretical density, a fine grain structure, and superior mechanical properties.

Understanding the Trade-offs

No manufacturing process is perfect for every application. To leverage pressing and sintering effectively, you must understand its limitations.

High Initial Tooling Costs

The hardened steel or carbide dies required for pressing are expensive to design and manufacture. This upfront investment means the process is generally not economical for low-volume production or prototyping.

Material and Size Constraints

The process is best suited for materials available in powder form. While the range of available metal powders is vast, it is not infinite. Additionally, there are practical limitations on the size and weight of parts that can be produced due to press tonnage and furnace capacity.

Controlled vs. Unwanted Porosity

While sintering reduces porosity, it can be difficult to eliminate it entirely with standard cold press methods. For applications requiring absolute hermetic sealing, this can be a drawback.

However, this same feature is a key advantage for creating self-lubricating bearings (where pores hold oil) or filters. The process allows you to control porosity for a specific function.

Making the Right Choice for Your Goal

Use this framework to determine if pressing and sintering aligns with your project's needs.

- If your primary focus is mass production of small, complex parts: This process offers unparalleled repeatability and cost-efficiency at scale, making it a superior choice to machining.

- If your primary focus is creating parts with unique material properties: Sintering is ideal for manufacturing components with engineered porosity for self-lubrication or filtration.

- If your primary focus is achieving maximum strength and density: Hot pressing is a powerful variant that produces parts with mechanical properties that can rival those made from wrought materials.

Understanding the distinct advantages of this process empowers you to make more intelligent and effective manufacturing decisions.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Complex Geometries | Produces intricate, non-machinable shapes and internal features. |

| High Repeatability | Ensures dimensional accuracy and consistency across large production runs. |

| Cost-Effectiveness | Minimizes material waste and post-processing for high-volume orders. |

| Enhanced Properties | Increases strength, durability, and thermal/electrical conductivity. |

| Controlled Porosity | Enables creation of self-lubricating bearings or filters. |

Ready to leverage pressing and sintering for your component needs?

KINTEK specializes in precision lab equipment and consumables for advanced manufacturing processes like powder metallurgy. Our expertise can help you achieve superior part quality, complex geometries, and significant cost savings in high-volume production.

Contact our experts today to discuss how our solutions can optimize your manufacturing strategy and bring your most challenging designs to life.

Visual Guide

Related Products

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What is the core function of a laboratory heated hydraulic press in CSP? Revolutionize Low-Temp Ceramic Sintering

- How does a hydraulic hot press contribute to the fabrication of all-solid-state battery cells? Enhance Ion Transport

- What is the purpose of using a laboratory hydraulic press for nanocomposites? Ensure Precise Material Characterization

- What role does a laboratory hydraulic hot press play in rice husk-based composite boards? Achieve Structural Density