Yes, biomass is a significant and growing source of fuel for transportation. It is converted into a range of liquid biofuels, such as ethanol and biodiesel, which can power conventional cars, trucks, and even aircraft, either on their own or blended with petroleum-based fuels.

While biomass is a proven pathway for creating renewable transportation fuels, its overall viability is not a simple matter. The true challenge lies in navigating the trade-offs between different biomass sources—the "food vs. fuel" dilemma—and developing cost-effective technologies to convert non-food materials into high-performance fuels.

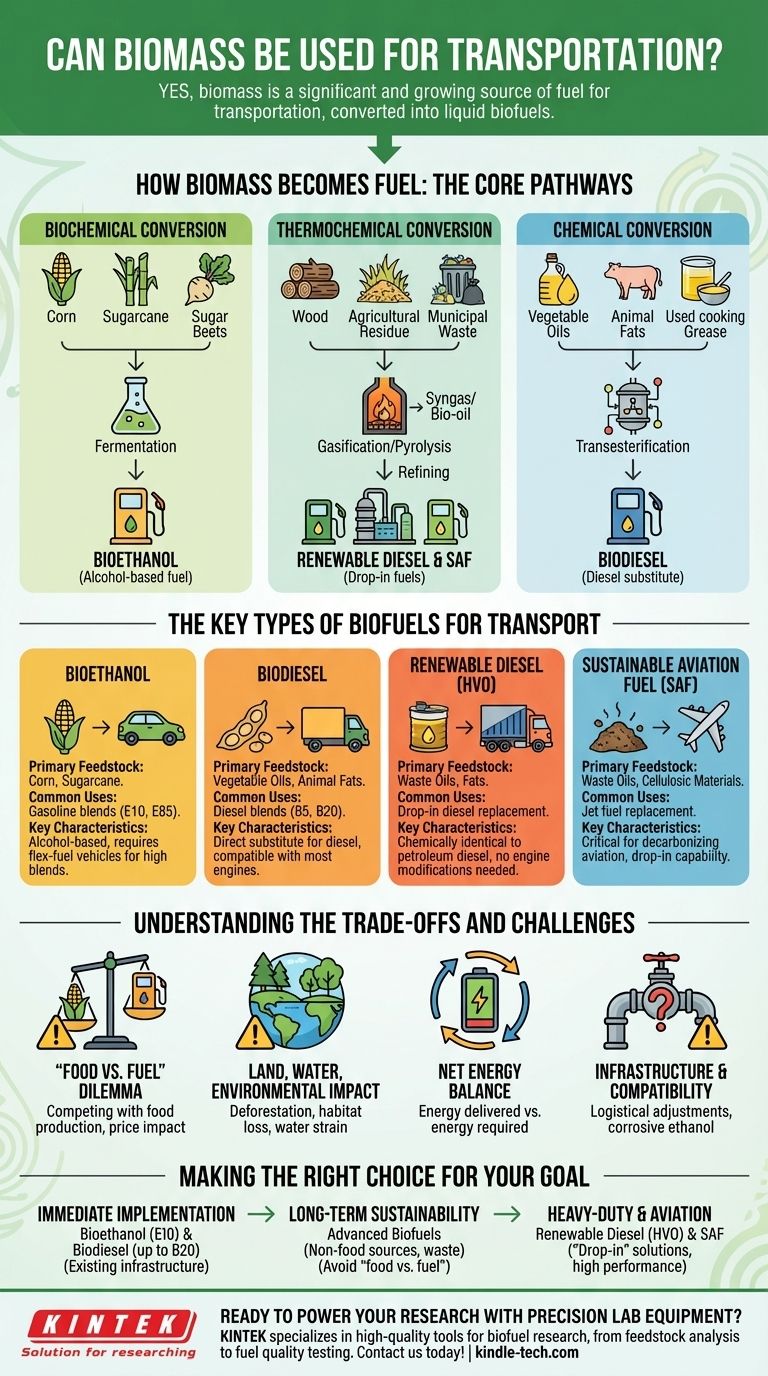

How Biomass Becomes Fuel: The Core Pathways

Biomass cannot be pumped directly into a vehicle; it must first be converted into a liquid fuel. This is accomplished through several distinct technological pathways, each suited for different types of raw materials.

Biochemical Conversion

This process uses microorganisms and enzymes to break down biomass. Fermentation is the most common example, where microbes consume plant sugars to produce bioethanol, in a process similar to brewing beer.

This method works best with feedstocks rich in sugars or starches, such as corn, sugarcane, and sugar beets.

Thermochemical Conversion

This pathway uses heat and catalysts to convert biomass. Processes like gasification and pyrolysis break down a wide range of organic matter—including wood, agricultural residue, and municipal waste—into an intermediate gas or oil.

This "syngas" or "bio-oil" can then be further refined into "drop-in" fuels like renewable diesel or sustainable aviation fuel, which are chemically identical to their fossil fuel counterparts.

Chemical Conversion

This involves direct chemical reactions to transform the biomass. The most established process is transesterification, where vegetable oils, animal fats, or used cooking grease are reacted with an alcohol (like methanol).

The result is biodiesel, a direct substitute for conventional diesel fuel.

The Key Types of Biofuels for Transport

The conversion processes yield several distinct types of fuel, each with specific applications and characteristics.

Bioethanol

Bioethanol is an alcohol-based fuel primarily used as a gasoline additive. Low-level blends like E10 (10% ethanol, 90% gasoline) are standard in many countries and require no vehicle modifications.

Higher blends like E85 (up to 85% ethanol) offer greater emission reductions but can only be used in specially designed "flex-fuel" vehicles.

Biodiesel

Biodiesel is a common substitute for petroleum diesel. It is typically blended with conventional diesel in formulations like B5 (5% biodiesel) or B20 (20% biodiesel) and is compatible with most modern diesel engines.

Its primary feedstocks are oil-rich crops like soybeans and canola, as well as waste vegetable oil and animal fats.

Renewable Diesel (HVO)

Often confused with biodiesel, renewable diesel—also known as Hydrotreated Vegetable Oil (HVO)—is a fundamentally different and higher-quality fuel. It is produced through a thermochemical process that makes it chemically indistinguishable from petroleum diesel.

As a "drop-in" fuel, it can be used at any blend level (up to 100%) in any diesel engine without modification and offers superior performance in cold weather.

Sustainable Aviation Fuel (SAF)

Representing the frontier of biofuel technology, SAF is a "drop-in" fuel designed to replace conventional jet fuel. It is currently produced in small but growing quantities from biomass feedstocks like waste oils and cellulosic materials.

SAF is considered a critical component for decarbonizing the aviation industry, which has few other viable alternative energy options.

Understanding the Trade-offs and Challenges

While biofuels present a clear renewable alternative, their production and use involve significant challenges that must be addressed for them to be truly sustainable.

The "Food vs. Fuel" Dilemma

The most prominent criticism is aimed at first-generation biofuels derived from food crops like corn and soybeans. Using agricultural land and resources to grow fuel can directly compete with food production, potentially driving up food prices and impacting global food security.

Land, Water, and Environmental Impact

Cultivating dedicated energy crops on a massive scale requires significant land and water resources. This can lead to deforestation, habitat loss, and strain on water supplies if not managed with strict sustainability standards.

Net Energy Balance

A critical technical hurdle is the net energy balance: the amount of energy delivered by the fuel versus the energy required to grow, harvest, transport, and convert the biomass. Early biofuels were criticized for having a poor or even negative energy return, though modern processes have improved this significantly.

Infrastructure and Compatibility

While drop-in fuels like renewable diesel integrate seamlessly, other biofuels require logistical adjustments. Ethanol, for instance, absorbs water and can be corrosive, meaning it cannot be transported in existing petroleum pipelines and requires specialized storage and blending infrastructure.

Making the Right Choice for Your Goal

The decision to use or invest in biomass for transportation depends entirely on the strategic priority. There is no single "best" solution, only the most appropriate one for a given objective.

- If your primary focus is immediate implementation with existing infrastructure: Bioethanol (as E10) and biodiesel blends (up to B20) are the most established and widely compatible options for the current vehicle fleet.

- If your primary focus is long-term sustainability and decarbonization: Prioritize advanced biofuels from non-food sources like cellulosic waste, municipal solid waste, and algae to avoid the "food vs. fuel" conflict.

- If your primary focus is heavy-duty transport and aviation: Renewable diesel (HVO) and Sustainable Aviation Fuel (SAF) are the most promising "drop-in" solutions that deliver high performance without requiring costly engine or infrastructure modifications.

Ultimately, harnessing biomass for transportation is a critical tool for reducing fossil fuel dependence, but its success hinges on developing sustainable feedstocks and efficient conversion technologies.

Summary Table:

| Biofuel Type | Primary Feedstock | Common Uses | Key Characteristics |

|---|---|---|---|

| Bioethanol | Corn, Sugarcane | Gasoline blends (E10, E85) | Alcohol-based, requires flex-fuel vehicles for high blends |

| Biodiesel | Vegetable Oils, Animal Fats | Diesel blends (B5, B20) | Direct substitute for diesel, compatible with most engines |

| Renewable Diesel (HVO) | Waste Oils, Fats | Drop-in diesel replacement | Chemically identical to petroleum diesel, no engine modifications needed |

| Sustainable Aviation Fuel (SAF) | Waste Oils, Cellulosic Materials | Jet fuel replacement | Critical for decarbonizing aviation, drop-in capability |

Ready to power your research with precision lab equipment?

As you explore the future of sustainable biofuels, having the right tools is essential for accurate analysis and development. KINTEK specializes in providing high-quality lab equipment and consumables tailored for biofuel research, from feedstock analysis to fuel quality testing.

Our products help researchers and engineers like you:

- Analyze feedstocks efficiently to select the best materials for conversion.

- Optimize conversion processes with reliable reactors and catalysts.

- Ensure fuel quality and compliance with precise testing instruments.

Whether you're working on biochemical conversion, thermochemical processes, or fuel blending, KINTEK has the equipment to support your innovation. Contact us today to discuss your specific laboratory needs and discover how we can help you achieve your biofuel research goals.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis