Yes, absolutely. A metal can be both compressed and bent, but these two actions describe fundamentally different responses to force that are governed by a material's internal atomic structure. While metals are incredibly resistant to being squeezed into a smaller volume (compression), they can be readily reshaped (bent) by pushing their atoms into new, permanent positions.

The core principle is this: Metals behave like a spring under small forces, returning to their original shape. But under larger forces, they bend and deform permanently. True compression, or reducing the metal's actual volume, requires immense, almost astronomical pressure because their atoms are already so tightly packed.

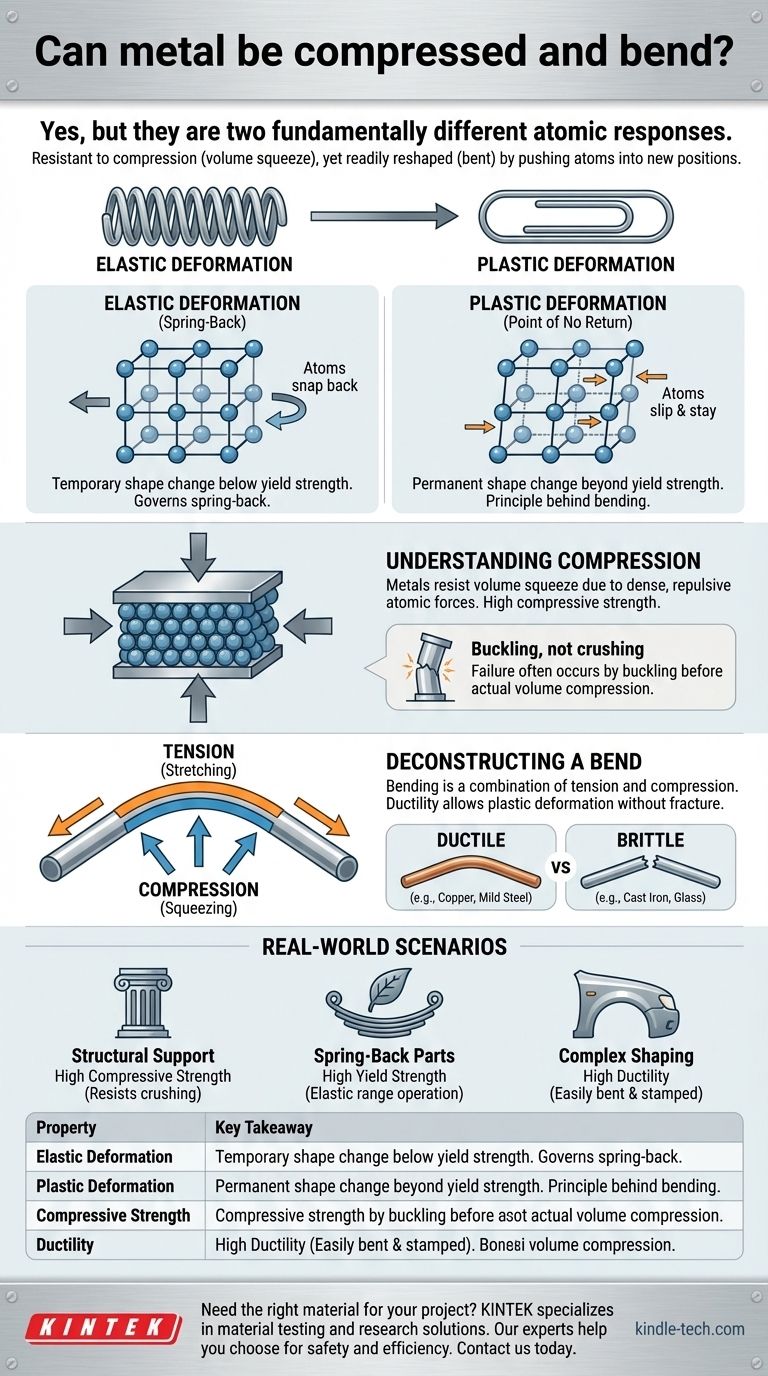

The Two Fundamental Responses of Metal: Elastic vs. Plastic

To understand how metals behave, we must first distinguish between two types of deformation. These principles govern everything from a bridge support to a paperclip.

Elastic Deformation: The Spring-Back Effect

When a small amount of force (stress) is applied to a metal, it deforms slightly (strain). The atoms in its crystal lattice are stretched apart or pushed together, but their bonds don't break.

If you remove the force, the atomic bonds pull everything back into its original position. This is elastic deformation. Think of it like gently pressing on a stiff spring; it gives a little but snaps right back when you let go.

Plastic Deformation: The Point of No Return

If you apply a force that exceeds the metal's elastic limit (also known as its yield strength), you start to cause permanent change.

The atoms are pushed so far that they slip past one another into new, stable positions within the crystal lattice. When the force is removed, the metal stays in its new shape. This is plastic deformation, and it is the physical principle behind bending.

Understanding Compression in Metals

When we talk about "compressing" a metal, it's crucial to be precise.

How Metals Resist Compression

Metals have a crystalline structure where atoms are packed together in a dense, orderly lattice. Strong metallic bonds hold them in place.

Trying to squeeze this structure into a smaller volume requires fighting the immense repulsive forces between the atomic nuclei. This is why metals are exceptionally stiff and possess very high compressive strength. For most practical engineering purposes, solids and liquids are considered incompressible.

What "Compressive Failure" Means

In the real world, a metal column under a heavy load doesn't fail by being crushed into a diamond. It typically fails by buckling—bowing outwards to the side—long before its material volume actually compresses in any meaningful way.

Deconstructing How Metal Bends

Bending is not a simple, single action. It's a complex combination of forces that leverages a metal's ability to deform plastically.

The Forces at Play in a Bend

Imagine bending a metal rod. You are simultaneously creating two different forces within the material:

- Tension: The atoms on the outer curve of the bend are being pulled apart.

- Compression: The atoms on the inner curve of the bend are being squeezed together.

The ability of the metal to stretch on the outside while squeezing on the inside without breaking is what allows it to bend.

The Role of Ductility

The property that allows for this permanent reshaping is ductility. Ductility is a metal's ability to undergo significant plastic deformation before fracturing.

Materials like copper and mild steel are very ductile, allowing them to be bent, stretched into wires, and hammered into sheets. In contrast, a brittle material like cast iron or glass will simply snap because it cannot deform plastically.

Common Pitfalls and Misconceptions

Understanding the nuances between these terms is key to avoiding common mistakes in design and material selection.

"Incompressible" is Relative

While we treat metals as incompressible in daily life, they are not truly so. Under the extreme pressures found in industrial forges or deep within the Earth's core, metal will compress and its density will increase. However, these forces are far beyond typical applications.

Not All Metals Are Equal

It is a mistake to think all metals behave the same way. The balance between strength, stiffness, and ductility varies enormously between different alloys.

A high-carbon tool steel is incredibly strong but brittle; it will snap before it bends much. A soft aluminum alloy is weak but highly ductile, bending with very little effort.

How This Applies to Real-World Scenarios

Choosing the right material always depends on understanding which property is most critical for your goal.

- If your primary focus is supporting a heavy load without crushing (like a building column): You need a material with high compressive strength.

- If your primary focus is creating a part that springs back (like a leaf spring): You need a material with a high yield strength that can operate in its elastic range without permanent bending.

- If your primary focus is shaping a material into a complex part (like a car fender): You need a material with high ductility that can be easily bent and stamped.

Understanding these foundational properties is the key to engineering materials that are both safe and perfectly suited to their task.

Summary Table:

| Property | Definition | Key Takeaway |

|---|---|---|

| Elastic Deformation | Temporary shape change; metal returns to original form when force is removed. | Governs spring-back behavior. Occurs below the yield strength. |

| Plastic Deformation | Permanent shape change; atoms slip into new positions. | The fundamental principle behind bending and shaping metals. |

| Compressive Strength | Resistance to being squeezed into a smaller volume. | Metals are highly resistant to compression due to their dense atomic lattice. |

| Ductility | The ability to undergo significant plastic deformation before fracturing. | Determines how easily a metal can be bent, stamped, or drawn. |

Need the Right Material for Your Project?

Understanding the difference between elastic and plastic deformation is crucial for selecting the right metal. Whether you need a highly ductile material for complex shaping or one with high compressive strength for structural support, KINTEK is here to help.

KINTEK specializes in providing high-quality laboratory equipment and consumables, serving diverse material testing and research needs. Our experts can help you choose the perfect materials and tools for your specific application, ensuring safety, efficiency, and optimal performance.

Contact our team today to discuss your material requirements and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual Lab Heat Press

People Also Ask

- What are the advantages of microwave pyrolysis? Faster, More Efficient Waste Conversion

- How do activators function in SHS coating? Master Gas-Phase Transport for Rapid Coating Deposition

- What is the name of the industrial furnace? A Guide to Classifying Heating Equipment

- What are the factors affecting the yield of bio-oil from the pyrolysis of coconut shell? Control 4 Key Parameters

- What is the mechanism of reactive sputtering? A Guide to Thin Film Deposition

- What is an ultra-low temperature freezer? Protect Your Most Valuable Biological Samples

- How to do sintering? Master the Process for High-Performance Ceramics & Metals

- What are the disadvantages of sintering? High Costs and Process Control Challenges