Yes, you can absolutely melt aluminum with induction heating. In fact, for many industrial and high-purity applications, induction is not just a viable option but the preferred method. Its efficiency, speed, and precision make it exceptionally well-suited for processing aluminum and its alloys.

Induction is a superior technology for melting aluminum in professional settings because it generates heat directly within the metal itself. This provides unparalleled speed, energy efficiency, and metallurgical control that older methods cannot match.

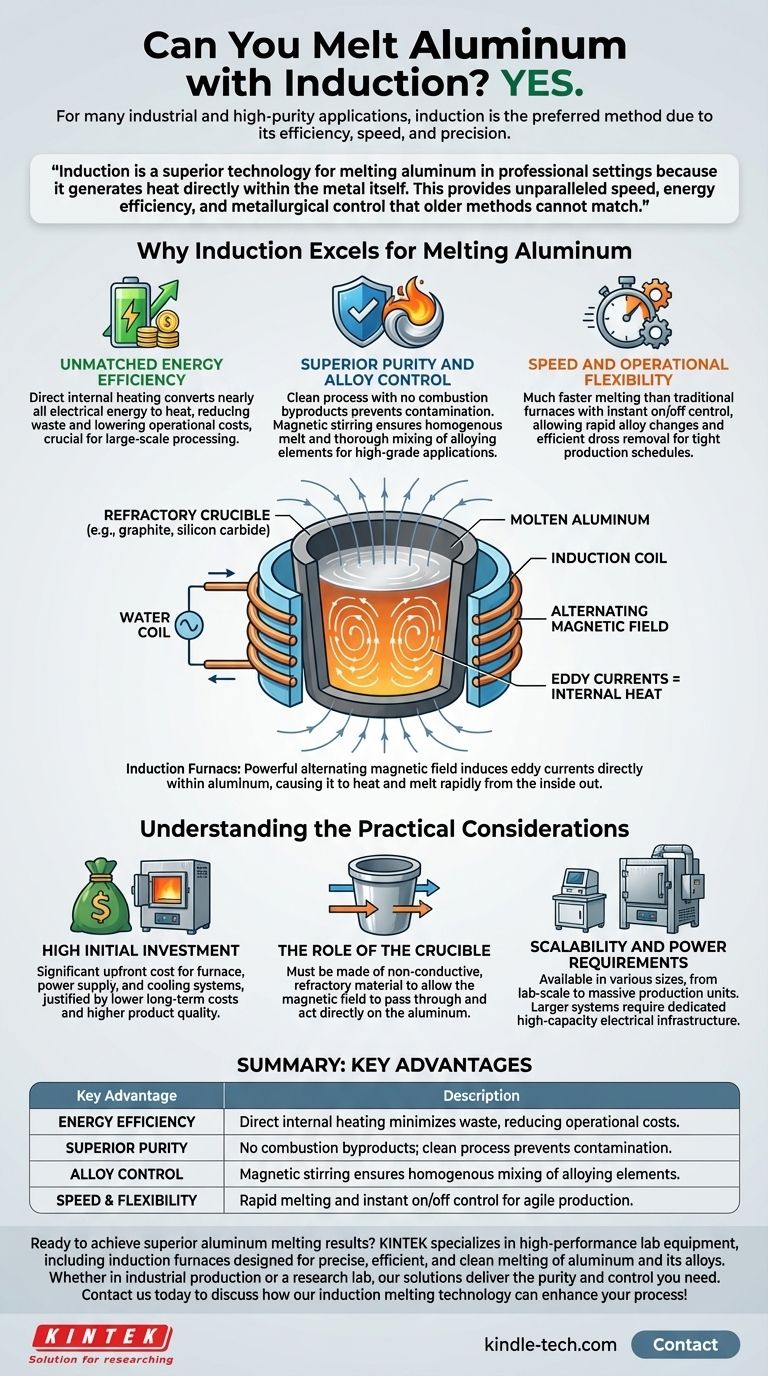

Why Induction Excels for Melting Aluminum

The core of induction heating lies in its method. Instead of applying external heat from a flame or a resistive element, an induction furnace uses a powerful, alternating magnetic field. This field induces strong electrical currents—known as eddy currents—directly within the aluminum, causing it to heat up and melt rapidly from the inside out.

Unmatched Energy Efficiency

Aluminum has a high specific heat and latent heat of fusion, meaning it requires a significant amount of energy to melt. Induction furnaces are highly efficient because nearly all the electrical energy is converted directly into heat within the aluminum charge, with very little waste. This translates directly to lower energy consumption and reduced operational costs, a critical factor in large-scale aluminum processing.

Superior Purity and Alloy Control

Because no combustion byproducts are involved, induction melting is an exceptionally clean process. This prevents impurities from being introduced into the melt. Furthermore, the magnetic field creates a natural stirring action, ensuring the molten metal is homogenous and that alloying elements are mixed thoroughly and evenly. This level of control is essential for producing high-grade aluminum alloys for demanding industries like aerospace.

Speed and Operational Flexibility

Induction furnaces can melt aluminum much faster than traditional furnaces. The ability to start and stop the heating process almost instantly allows for rapid alloy changes and efficient dross removal. This operational agility is a significant advantage in modern casting facilities where production schedules are tight and product specifications vary.

Understanding the Practical Considerations

While highly effective, induction melting is a sophisticated process with specific requirements. Understanding these trade-offs is key to determining if it's the right choice for your specific application.

High Initial Investment

The primary barrier to entry for induction melting is the cost of the equipment. An induction furnace, its power supply, and the associated cooling systems represent a significantly higher upfront investment compared to a simple gas-fired or resistance furnace. This cost is typically justified by lower long-term operating costs and higher product quality in commercial settings.

The Role of the Crucible

The aluminum must be held in a container called a crucible. For induction melting, this crucible must be made of a non-conductive, refractory material like graphite or silicon carbide. This allows the magnetic field to pass through the crucible and act directly on the aluminum. Using the wrong type of crucible will render the process ineffective.

Scalability and Power Requirements

Induction systems range from small, benchtop units for jewelers and labs to massive furnaces capable of melting many tons of metal. The size and power of the unit must be matched to the volume of aluminum you intend to melt. Larger systems require a dedicated, high-capacity electrical infrastructure.

Making the Right Choice for Your Goal

Selecting a melting method depends entirely on your project's scale, budget, and quality requirements.

- If your primary focus is high-volume industrial production or casting critical alloys: Induction is the industry standard due to its efficiency, speed, and superior metallurgical control.

- If your primary focus is small-scale or hobbyist metal casting: Induction is a premium option that offers excellent results, but you must weigh its high initial cost against simpler and cheaper methods like propane forges.

- If your primary focus is achieving the highest possible purity: The clean, contained nature of induction melting makes it the ideal choice for applications where contamination is not an option.

By understanding these core principles, you can confidently determine whether induction technology is the correct tool for your aluminum melting objectives.

Summary Table:

| Key Advantage | Description |

|---|---|

| Energy Efficiency | Direct internal heating minimizes energy waste, reducing operational costs. |

| Superior Purity | No combustion byproducts; clean process prevents contamination. |

| Alloy Control | Magnetic stirring ensures homogenous mixing of alloying elements. |

| Speed & Flexibility | Rapid melting and instant on/off control for agile production. |

Ready to achieve superior aluminum melting results?

KINTEK specializes in high-performance lab equipment, including induction furnaces designed for precise, efficient, and clean melting of aluminum and its alloys. Whether you're in industrial production or a research lab, our solutions deliver the purity and control you need.

Contact us today to discuss how our induction melting technology can enhance your process!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance